Method for encapsulating homogeneous catalyst in pore channels of mesoporous molecular sieve

A homogeneous catalyst and mesoporous molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as difficult separation and non-reusable use, achieve low price, realize separation and repeated use , the effect of a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

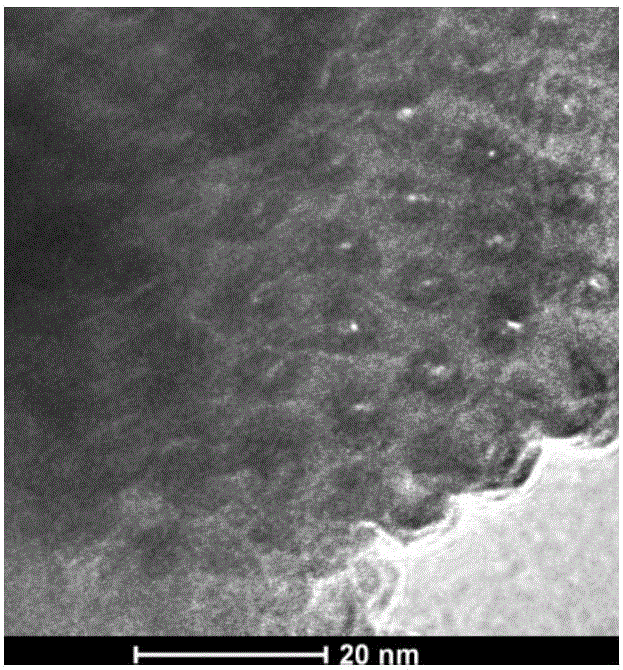

[0042] Dissolve b in dichloromethane with magnetic stirring to make a 0.001 g / mL solution. According to the ratio of molecular sieve volume and vacuum chamber as 1:10, put SBA-15 into a vacuum bottle to pump air, and pump SBA-15 at 120°C for 12 hours, and then press the mass ratio of b to SBA-15 1:0.01, inject the prepared homogeneous solution into the vacuum bottle containing SBA-15 and stir vigorously for 12 hours, then drain the dichloromethane solvent in the system at 40°C in vacuum, and the obtained sample is b / SBA-15 15.

[0043] Weigh sample b / SBA-15 and place it on a quartz plate, and smear it evenly with petroleum ether to control the thickness at 1 mm. Then place the dried quartz sheet in vacuum atomic layer deposition (ALD) equipment. Deposition of Al on SBA-15 orifices by atomic layer deposition 2 o 3 Implement encapsulation. The set deposition parameters are as follows: the deposition temperature is 100° C., the temperature of the reaction source trimethylalu...

Embodiment 2

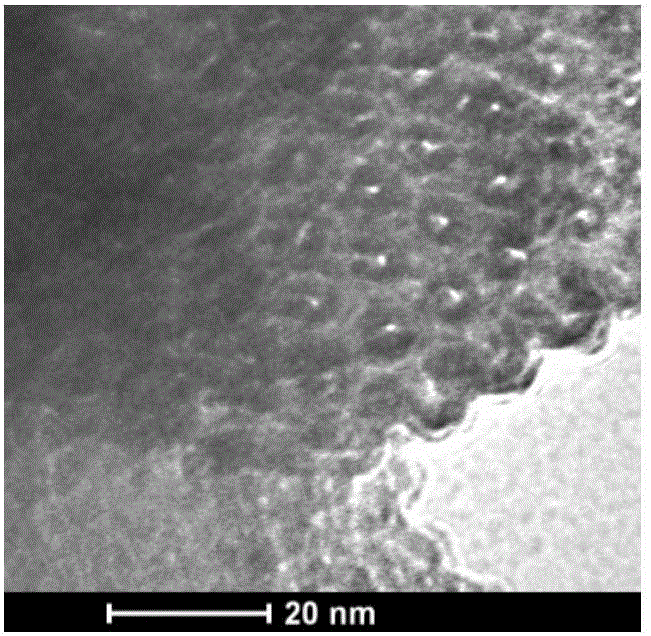

[0046] Dissolve c in toluene and stir magnetically to form a 0.01g / mL solution. According to the ratio of molecular sieve volume and vacuum chamber as 1:50, put MCM-41 into a vacuum bottle to pump air. At 80°C, pump MCM-41 for 24 hours, and then press c and the mass of MCM-41 The ratio is 1:10, inject the prepared homogeneous solution into the vacuum bottle containing MCM-41 and stir vigorously for 18 hours, then drain the toluene solvent in the system at 60°C in vacuum, and the obtained sample is c / MCM-41 .

[0047] Weigh the sample c / MCM-41 and place it on a quartz plate, and smear it evenly with ethanol to control the thickness at 2 mm. Then place the dried quartz sheet in vacuum atomic layer deposition (ALD) equipment. Deposition of TiO at MCM-41 Orifices by Atomic Layer Deposition 2 Implement encapsulation. The deposition parameters are set as follows: the deposition temperature is 60° C., the temperatures of the reaction source titanium tetraisopropoxide and water ar...

Embodiment 3

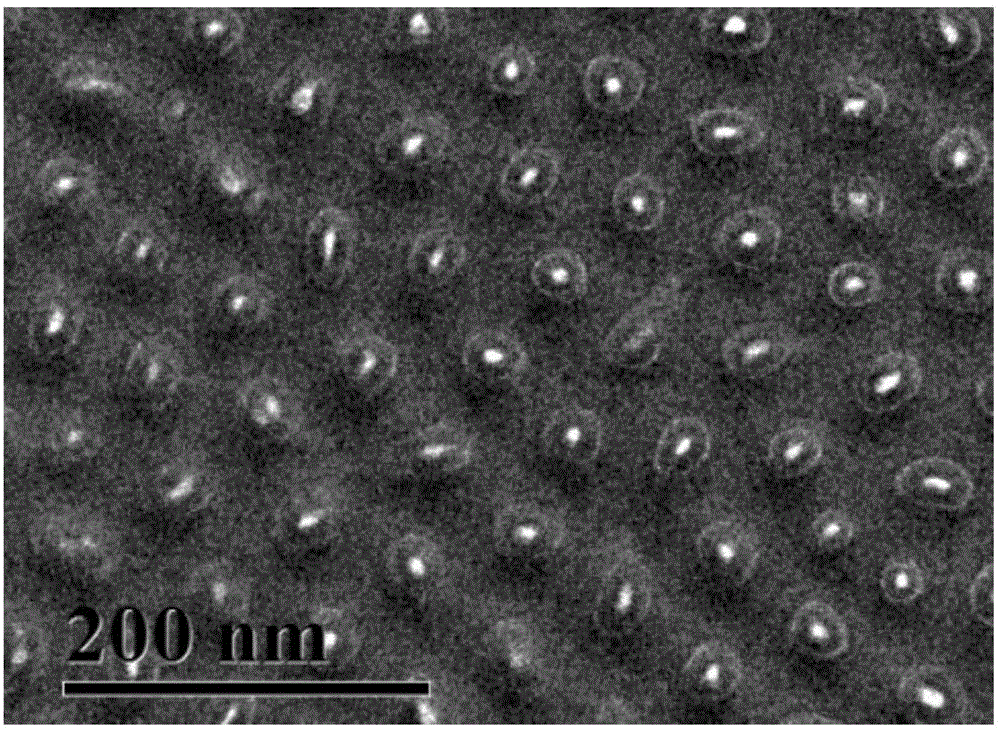

[0050] Dissolve d in chloroform with magnetic stirring to make a 1 g / mL solution. According to the ratio of molecular sieve volume to vacuum chamber 1:100, put SBA-16 into a vacuum bottle to pump air, and pump SBA-16 at 100°C for 18 hours, and then press the mass ratio of d to SBA-16 1:100, inject the prepared homogeneous solution into the vacuum bottle containing SBA-16 and stir vigorously for 24 hours, then drain the chloroform solvent in the system at 80°C in vacuum, and the obtained sample is d / SBA-16.

[0051] Weigh sample d / SBA-16 and place it on a quartz plate, and smear it evenly with dichloromethane to control the thickness at 0.5 mm. Then place the dried quartz sheet in vacuum atomic layer deposition (ALD) equipment. Encapsulation is achieved by depositing ZnO at the orifice of SBA-16 by atomic layer deposition. The deposition parameters are set as follows: the deposition temperature is 50° C., the temperatures of the reaction source diethyl zinc and water are 60° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com