Novel water-based automobile surface lacquer

An automotive surface, water-based technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of decreased wear and scratch resistance, high material requirements, poor outdoor durability, etc., to achieve enhanced adhesion, gloss The effect of high and VOC emission control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

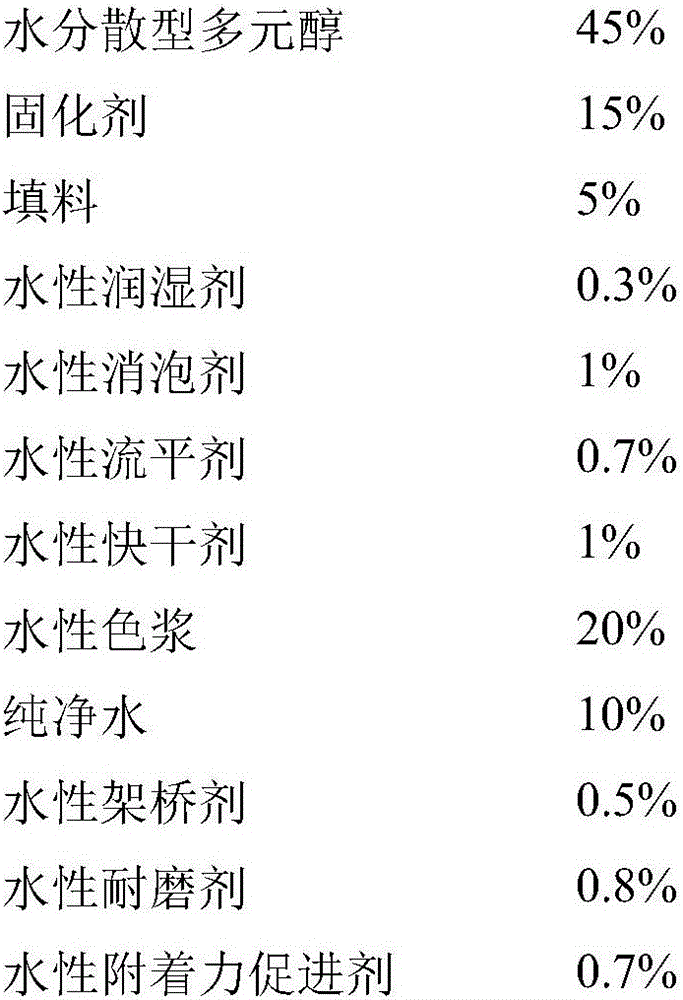

Embodiment 1

[0039] The raw materials and reagents described in this embodiment mainly include: water-dispersible polyols are selected from hydroxyacrylate aqueous dispersion; water-based isocyanate curing agent is Bayhydur XP 2655 from Bayer; filler is from Hongna New Material Technology Co., Ltd. The water-based graphene slurry; the water-based quick-drying agent is a product of our company, model GS-A006, which is a white emulsion of high molecular weight zinc oxide. Its preparation method is: first dissolve 112g of ammonium carbonate with 154g of water for 3 to 5 minutes, Add 75g zinc oxide again, become opaque liquid after 2~3 minutes, add the ammoniacal liquor of 28% concentration of 159g again, promptly obtain 500g content be the zinc oxide solution of 15% after 3~5 minutes, get 15 parts of zinc oxide solutions, Sequentially add 2 parts of 28% ammonia water, 15 parts of deionized water and 68 parts of water-based acrylic emulsion (Argentina diransa, model SF) to the zinc oxide soluti...

Embodiment 2

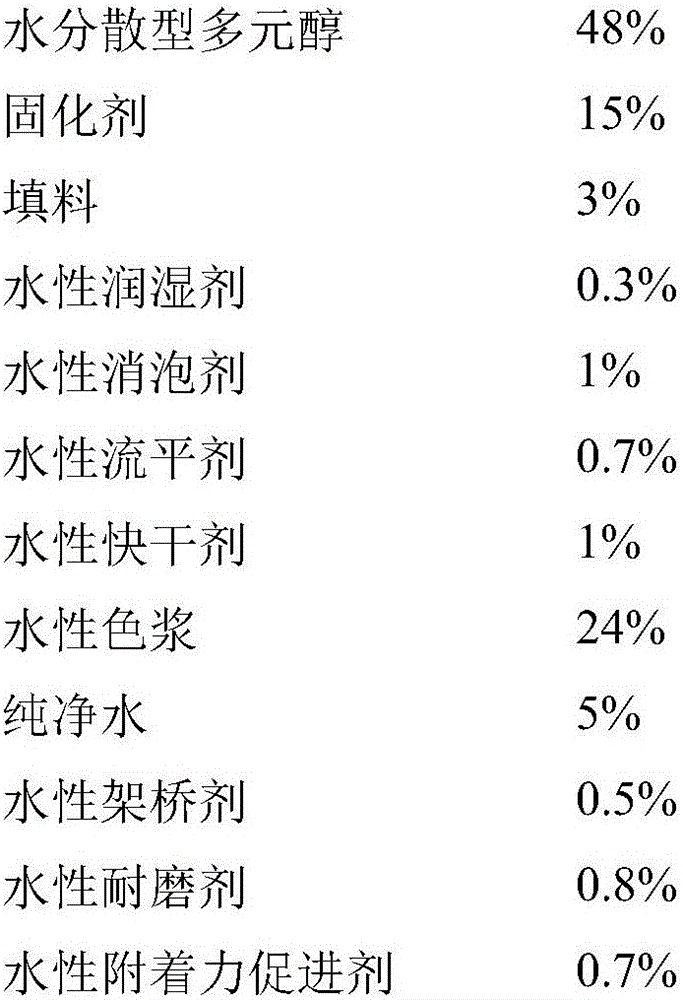

[0047] The raw materials and reagents described in this embodiment mainly include: water-dispersible polyols are selected from hydroxyacrylate aqueous dispersion; water-based isocyanate curing agent is Bayhydur XP 2655 from Bayer; filler is from Hongna New Material Technology Co., Ltd. The water-based graphene slurry; the water-based quick-drying agent is a product of our company, model GS-A006, which is a white emulsion of high molecular weight zinc oxide. Its preparation method is: first dissolve 112g of ammonium carbonate with 154g of water for 3 to 5 minutes, Add 75g zinc oxide again, become opaque liquid after 2~3 minutes, add the ammoniacal liquor of 28% concentration of 159g again, obtain 500g content be the zinc oxide solution of 15% after 3~5 minutes, get 15 parts of zinc oxide solutions, Add 2 parts of 28% ammonia water, 15 parts of deionized water and 68 parts of water-based acrylic emulsion (Argentina diransa, model SF) to the zinc oxide solution in sequence, which ...

Embodiment 3

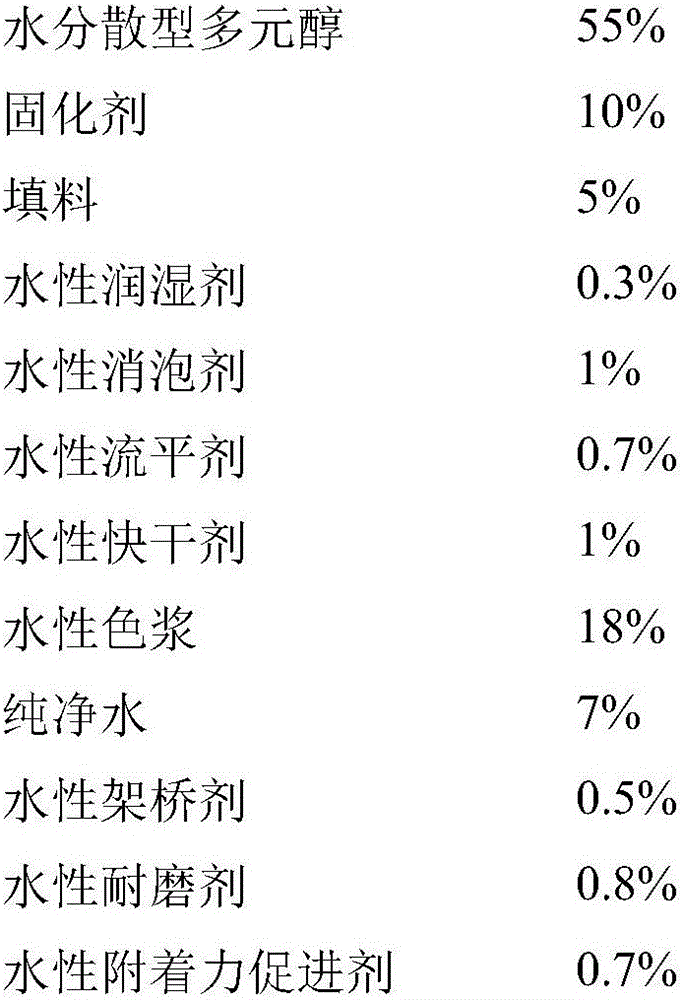

[0055] The raw materials and reagents described in this embodiment mainly include: water-dispersible polyols are selected from hydroxyacrylate aqueous dispersion; water-based isocyanate curing agent is Bayhydur XP 2655 from Bayer; filler is from Hongna New Material Technology Co., Ltd. The water-based graphene slurry; the water-based quick-drying agent is a product of our company, model GS-A006, which is a white emulsion of high molecular weight zinc oxide. Its preparation method is: first dissolve 112g of ammonium carbonate with 154g of water for 3 to 5 minutes, Add 75g zinc oxide again, become opaque liquid after 2~3 minutes, add the ammoniacal liquor of 28% concentration of 159g again, promptly obtain 500g content be the zinc oxide solution of 15% after 3~5 minutes, get 15 parts of zinc oxide solutions, Sequentially add 2 parts of 28% ammonia water, 15 parts of deionized water and 68 parts of water-based acrylic emulsion (Argentina diransa, model SF) to the zinc oxide soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com