Preparation method of supported catalyst with anchoring enhanced NOx removal

A catalyst and carrier technology, applied in the field of carrier catalyst preparation, can solve the problems of narrow catalyst temperature window, cumbersome and complicated preparation process, and less enrichment coating amount, etc., to solve uneven coating, low firmness, and wide temperature range window effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

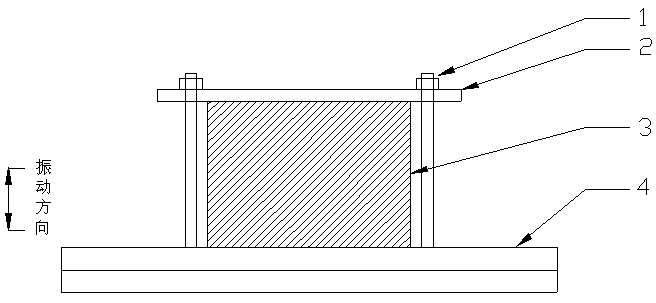

Image

Examples

Embodiment 1

[0014] (1) Pretreatment of cordierite honeycomb carrier

[0015] Soak the cordierite ceramic carrier in 2% ammonia water at room temperature, take it out after 60 minutes, rinse it with deionized water repeatedly until the pH of the solution after washing is neutral, dry it at 105°C, and calcinate at 500°C for 4 hours .

[0016] (2) Preparation of anchoring enhancement mixture

[0017] a. Weigh 300g of copper nitrate, 240g of ferric nitrate, 120g of cerium nitrate and dissolve in 5300g of deionized water; b. Add 1200g of Sapo34 molecular sieve powder and stir for 2h; c. Add 21.2g of ammonium carbamate and stir for 1h at 60°C; 400g silica sol (SiO 2 content is 40%), 450g aluminum sol (Al 2 o 3 content is 40%), 400g sodium carboxymethyl cellulose aqueous solution (mass fraction 1%), and stir evenly to obtain a mixed solution.

[0018] (3) Activation of cordierite honeycomb support

[0019] Put the cordierite honeycomb carrier obtained after the pretreatment in (1) into the...

Embodiment 2

[0025] (1) Pretreatment of cordierite honeycomb carrier

[0026] Soak the cordierite ceramic carrier in 3.8% ammonia water at room temperature, take it out after 60 minutes, rinse it with deionized water repeatedly until the pH of the solution after washing is neutral, dry it at 105°C, and calcinate at 500°C for 4h .

[0027] (2) Preparation of anchoring enhancement mixture

[0028] a. Weigh 480g of copper nitrate, 400g of ferric nitrate, 150g of lanthanum nitrate and dissolve in 5200g of deionized water; b. Add 1200g of ZSM5 molecular sieve powder and stir for 4h; c. Add 34.2g of ammonium carbamate and stir for 3h at 45°C; 180g silica sol (SiO 2Content is 40%), 200g aluminum sol (Al 2 o 3 content of 40%), 550g sodium carboxymethyl cellulose aqueous solution (mass fraction 1%), and stir evenly to obtain a mixed solution.

[0029] (3) Activation of cordierite honeycomb support

[0030] Put the cordierite honeycomb carrier obtained after pretreatment in (1) into the molecu...

Embodiment 3

[0032] (1) Pretreatment of cordierite honeycomb carrier

[0033] Soak the cordierite ceramic carrier in 2% ammonia water at room temperature, take it out after 30 minutes, rinse it with deionized water repeatedly until the pH of the solution after washing is neutral, dry it at 105°C, and calcinate at 500°C for 3 hours .

[0034] (2) Preparation of anchoring enhancement mixture

[0035] a. Weigh 400g of copper nitrate, 400g of ferric nitrate, 180g of manganese nitrate and dissolve in 6200g of deionized water; b. Add 1200g of Sapo34 molecular sieve powder and stir for 2h; c. Add 32.8g of ammonium carbamate and stir for 2h at 55°C; 350g silica sol (SiO 2 content is 40%), 300g aluminum sol (Al 2 o 3 content of 40%), 180g sodium carboxymethyl cellulose aqueous solution (mass fraction 1%), and stir evenly to obtain a mixed solution.

[0036] (3) Activation of cordierite honeycomb support

[0037] Put the cordierite honeycomb carrier obtained after pretreatment in (1) into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com