Soft glazed ceramic tile and preparation method thereof

A ceramic tile and soft light technology, which is applied in the field of architectural ceramics, can solve the problems of toxicity, high acidity, and increased production costs, and achieve the effects of soft luster, uniform and soft luster, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

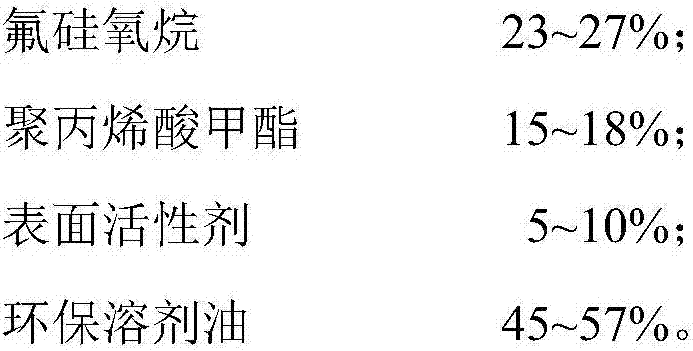

Method used

Image

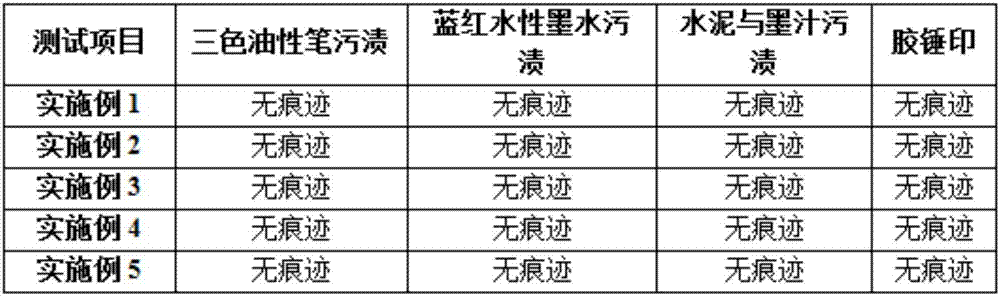

Examples

Embodiment 1

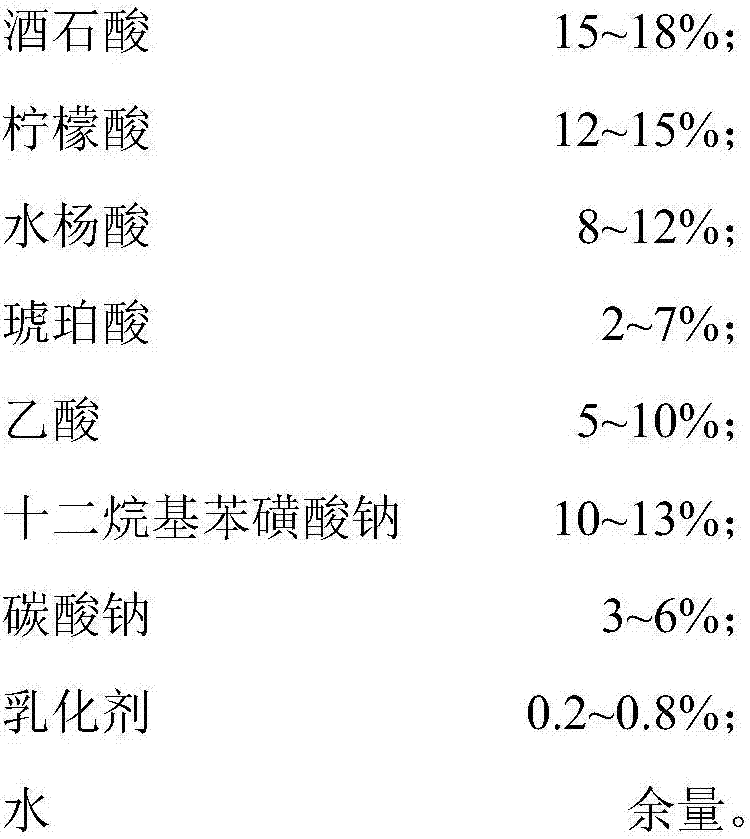

[0021] On the surface of semi-finished polished glazed tiles after fine polishing, the amount of polishing coating is 75g / m 2 , an environmentally friendly water-soluble corrosion inhibitor for polishing, after repeated polishing of 15 sets of planetary grinding discs, a soft surface layer is formed; the amount of polishing plating is 75g / m 2 , polishing and plating penetrating antifouling agent, through repeated polishing of 3 groups of planetary grinding discs, it forms a penetrating antifouling film layer on the brick surface, and the soft light ceramic tile of Example 1 with a brick surface gloss of 10 degrees is obtained.

[0022] The pH value of the environment-friendly water-soluble corrosion inhibitor described in this example is 6, which includes: 15% tartaric acid, 15% citric acid, 8% salicylic acid, 2% succinic acid, and 10% acetic acid in terms of raw material weight percentage 10% sodium dodecylbenzenesulfonate, 6% sodium carbonate, 0.2% emulsifier and the balance...

Embodiment 2

[0024] On the surface of semi-finished polished tiles after fine polishing, the amount of plating is 50g / m 2 , an environmentally friendly water-soluble corrosion inhibitor for polishing, after repeated polishing by 12 groups of planetary grinding discs, a soft surface layer is formed; the amount of polishing coating is 25g / m 2 , polishing and plating penetrating antifouling agent, through repeated polishing of 6 groups of planetary grinding discs, it forms a penetrating antifouling film layer on the brick surface, and obtains the soft light ceramic tile of Example 2 with a brick surface glossiness of 35 degrees.

[0025] The pH value of the environment-friendly water-soluble corrosion inhibitor described in this example is 6.5, which includes: 18% tartaric acid, 12% citric acid, 10% salicylic acid, 7% succinic acid, 5% acetic acid in terms of raw material weight percentage 13% sodium dodecylbenzenesulfonate, 3% sodium carbonate, 0.8% emulsifier and the balance of water. The ...

Embodiment 3

[0027] On the surface of semi-finished polished glazed tiles after fine polishing, the dosage of polishing plating is 25g / m 2 , an environmentally friendly water-soluble corrosion inhibitor for polishing, after repeated polishing of 15 sets of planetary grinding discs, a soft surface layer is formed; the amount of polishing plating is 25g / m 2 , polishing and plating penetrating antifouling agent, through repeated polishing of 3 groups of planetary grinding discs, it forms a penetrating antifouling film layer on the brick surface, and obtains the soft light ceramic tile of Example 3 with a brick surface gloss of 50 degrees.

[0028] The pH value of the environment-friendly water-soluble corrosion inhibitor described in this example is 6.2, which includes: 16% tartaric acid, 13% citric acid, 12% salicylic acid, 5% succinic acid, 8% acetic acid in terms of raw material weight percentage 12% sodium dodecylbenzenesulfonate, 5% sodium carbonate, 0.5% emulsifier and the balance of wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com