Lithium-sulfur battery, assembly thereof and application of functional material layer in lithium-sulfur battery

A functional material, lithium-sulfur battery technology, applied to battery components, battery electrodes, lithium batteries, etc., can solve problems such as unsatisfactory effects, and achieve the effects of improving electrochemical performance, inhibiting shuttle, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

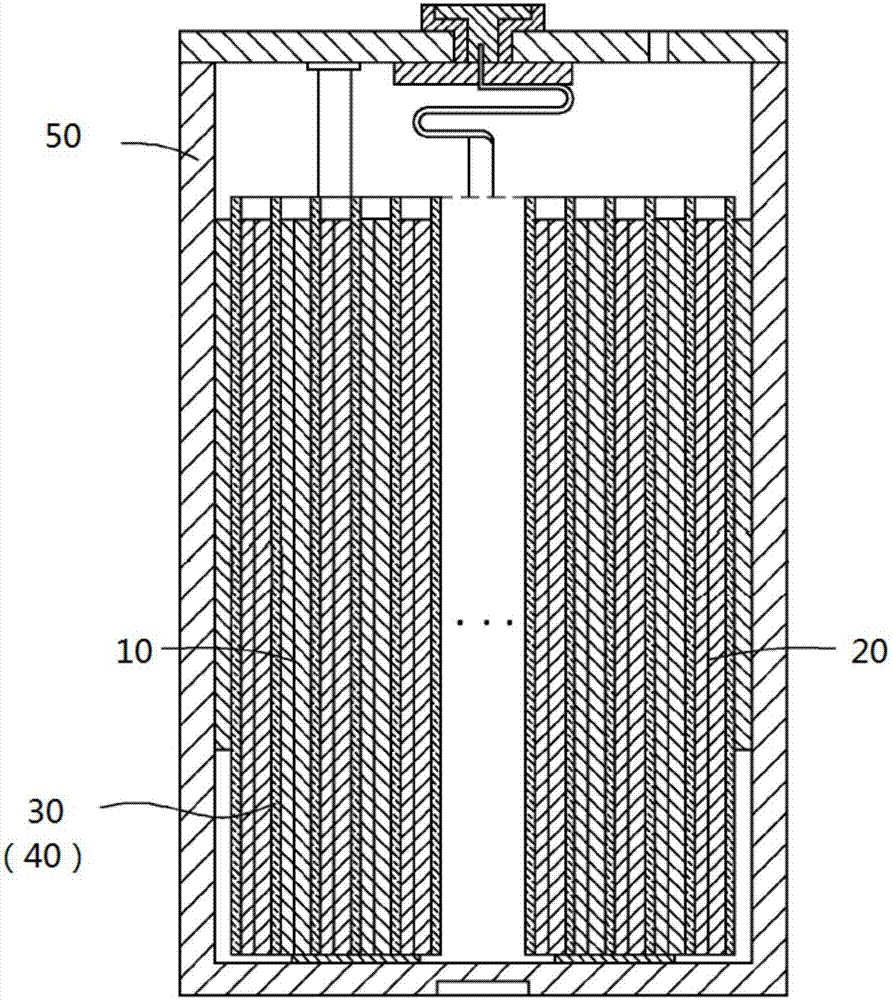

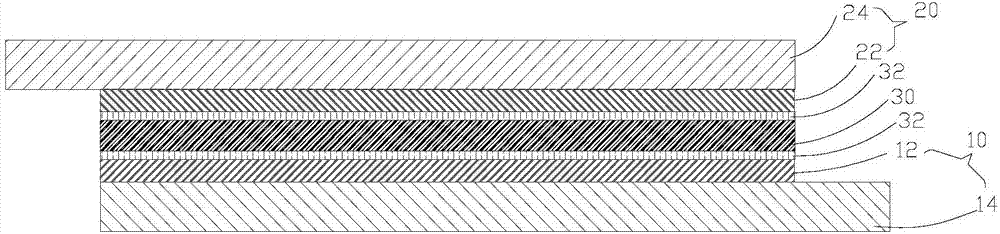

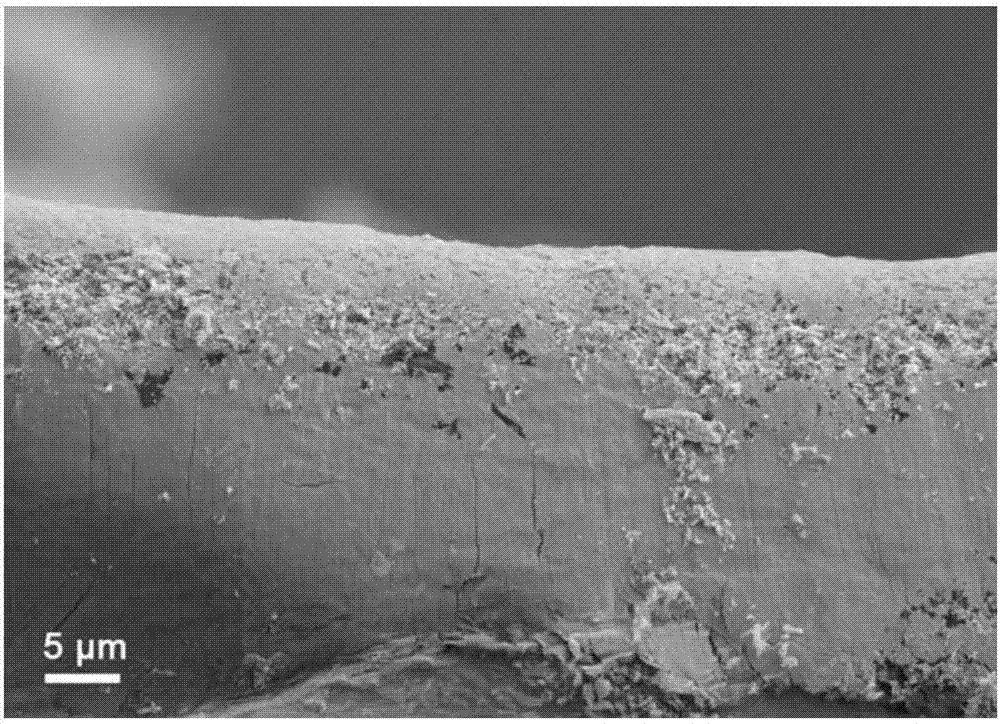

[0076] 1) Preparation of Li-H-M-O system compound-based functional material layer: Li 1.81 h 0.19 Ti 2 o 5-σ (σ represents oxygen vacancies), Super P and PVDF were added to N-methylpyrrolidone at a mass ratio of 8:1:1 and mixed to form a slurry, and then coated on one side of the polypropylene separator by casting method The above slurry was then vacuum-dried at 60°C for 10 hours to obtain a composite separator with a Li-H-Ti-O system compound-based functional material layer (hereinafter referred to as PP@C&LHTO-1). Scanning electron microscope (SEM) image of functional material layer in PP@C&LHTO-1 image 3 shown.

[0077] 2) Assembly of lithium-sulfur battery: Sublimated sulfur is used to prepare sulfur positive electrode, metal lithium sheet is used as negative electrode, PP@C&LHTO-1 is used as separator, and electrolyte is LiTFSI and LiNO 3 The mixed solution formed in the mixed solvent of DME and DOL (the volume ratio of DME and DOL is 1:1, the concentration of LiTFS...

Embodiment 2

[0091] 1) Preparation of functional material layer with Li-H-M-O system compound: Li 0.71 h 0.49 mn 1.73 o 3.88 , Ketjen Black, and PVDF were added to ethanol solvent at a mass ratio of 7:2:1 and mixed to form a slurry, and then the above slurry was coated on both sides of the polyethylene diaphragm by spin coating, and then the slurry was heated at 80°C After drying under vacuum for 10 hours, a composite separator with a Li-H-Mn-O system compound-based functional material layer (hereinafter referred to as PE@C&LHMO-2) was obtained.

[0092] 2) Assembly of lithium-sulfur battery: the same as in Example 1, the only difference is that PP@C&LHTO-1 is replaced by PE@C&LHMO-2.

Embodiment 3

[0094] 1) Preparation of functional material layer with Li-H-M-O system compound: 7Li 2 WO 4 4H 2 O, acetylene black, and LA were added to deionized water at a mass ratio of 85:15:5 and mixed to form a slurry, and then the polyethylene-polypropylene double-layer diaphragm was coated on one side with the suction filtration (filtration) coating method. slurry, and then vacuum-dried the slurry at 80°C for 10 hours to obtain a composite separator with a Li-H-W-O system compound-based functional material layer (hereinafter referred to as PE / PP@C&LHWO-3).

[0095] 2) Lithium-sulfur battery assembly: the same as in Example 1, the only difference is that the sublimated sulfur is replaced by a sulfur-carbon composite material, and PP@C&LHTO-1 is replaced by PE / PP@C&LHWO-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com