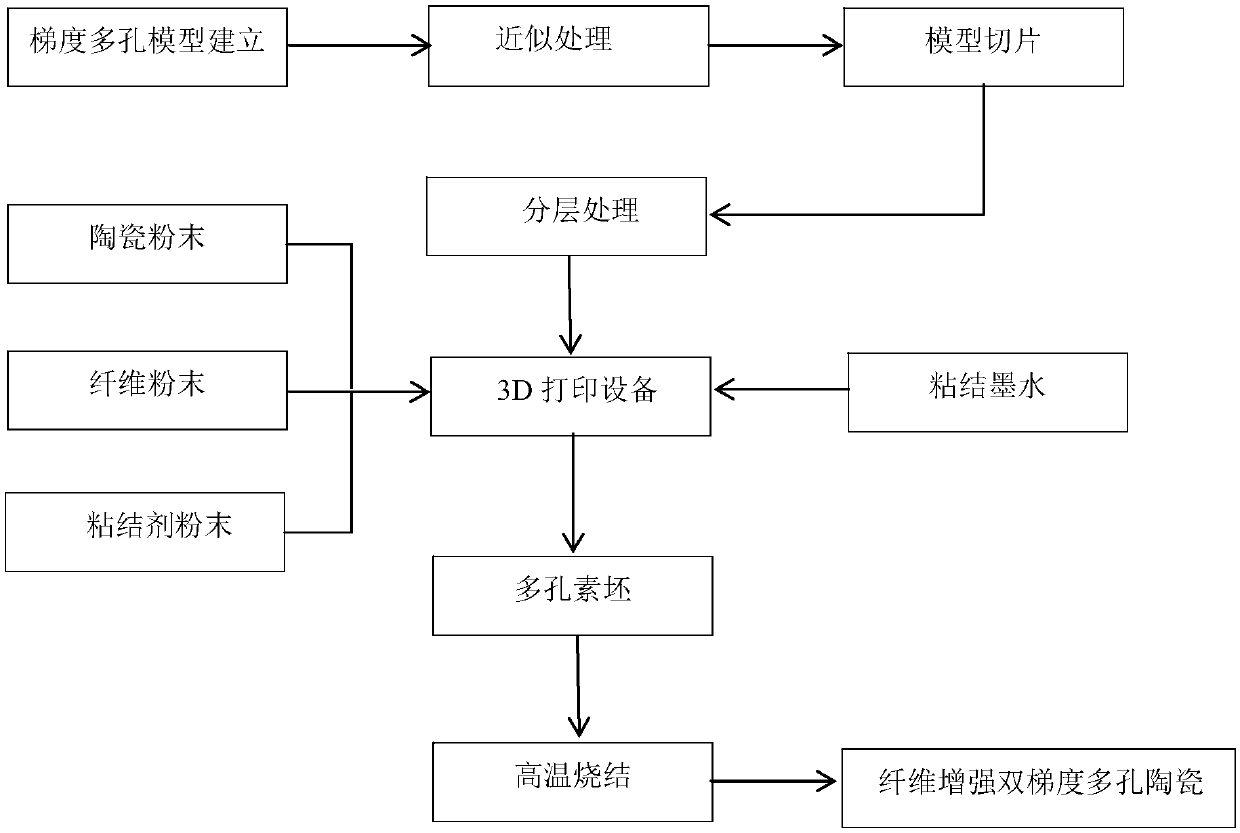

Method for manufacturing fiber reinforced gradient porous ceramic based on 3D printing

A manufacturing method and fiber-reinforced technology, applied in the field of 3D printing rapid prototyping, can solve the problems of difficult continuous change of materials, difficulty in controlling the pore size and distribution of gradient porous ceramics, etc., to reduce dust bridging, facilitate dust removal, and improve application The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

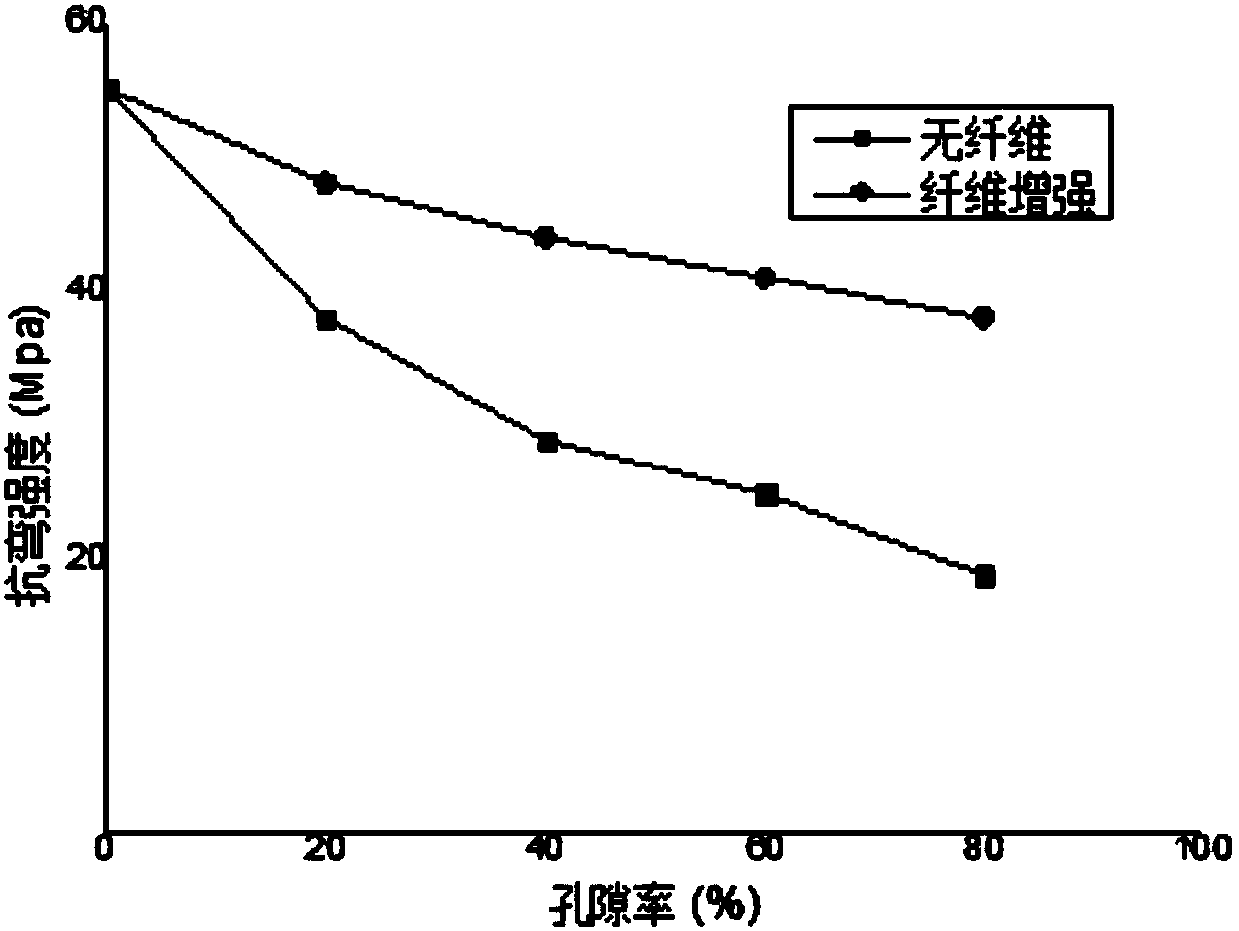

[0039] 1) Use computer-aided design modeling software: CAD, UG, Pro / E, etc. to design a three-dimensional solid model of gradient pore structure (pore gradient is 20% to 80%) according to the requirements of product pore size, pore distribution, and pore shape. The 3D model was approximated to obtain the STL format file, and the 3D model was discretized into a series of ordered 2D layers along the forming height direction with a layer interval of 0.1 mm. The 3D printer software guided the printer to print layer by layer. In this embodiment, printing of five layers is taken as an example, and Table 1 shows the porosity distribution of the three-dimensional model in this embodiment.

[0040] 2) To form gradient porous ceramics, the composition ratio requirements of each layer are: from the bottom to the top, the mass fraction of carbon fiber in each layer is: 0%, 13%, 22%, 26%, and 30%, and the mass fraction of polyvinyl alcohol is 8%. , the mass fractions of alumina are: 92%, 7...

Embodiment 2

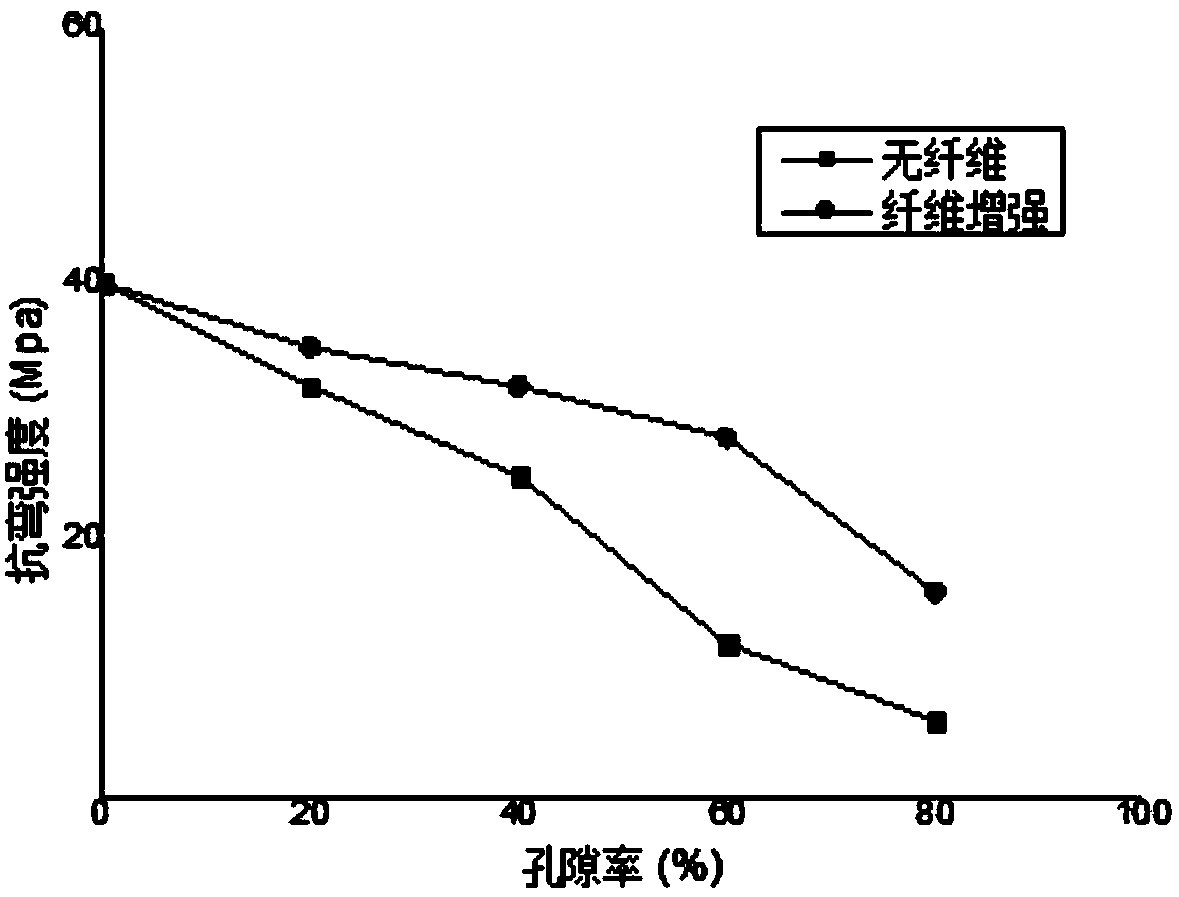

[0050] 1) Use computer-aided design modeling software: CAD, UG, Pro / E, etc. to design a three-dimensional solid model of gradient pore structure according to the requirements of product pore size, pore distribution, and pore shape (the pore gradient is 20% to 80%, see Table 1), approximate the 3D model to obtain the STL format file, discretize the 3D model into a series of ordered 2D layers along the forming height direction, the layer interval is 0.1 mm, and the 3D printer software guides the printer to print layer by layer.

[0051] 2) The component ratio requirements for forming gradient porous ceramics are: from the bottom to the top, the mass fractions of carbon fibers in each layer are: 0%, 11%, 19%, 25%, 30%, the mass fraction of polyvinyl alcohol is 8%, silicon carbide The mass fractions are: 92%, 81%, 73%, 67%, 62%, respectively.

[0052] 3) Add bonding ink to the nozzle, wherein the bonding ink is composed of distilled water, glycerol and polyvinylpyrrolidone; the di...

Embodiment 3

[0057] 1) Use computer-aided design modeling software: CAD, UG, Pro / E, etc. to design a three-dimensional solid model of gradient pore structure (pore gradient is 60% to 70%) according to the requirements of product pore size, pore distribution, and pore shape. The 3D model was approximated to obtain the STL format file, and the 3D model was discretized into a series of ordered 2D layers along the forming height direction with a layer interval of 0.1 mm. The 3D printer software guided the printer to print layer by layer.

[0058] 2) The composition ratio requirements for forming gradient porous ceramics are as follows: from the bottom to the top, the mass fraction of silicon carbide fibers in each layer is 0%, 16%, 24%, 28%, and 33%, and the mass fraction of polyvinyl alcohol is 8%. Silicon mass fractions are: 92%, 76%, 68%, 64%, 59%.

[0059] 3) Add bonding ink to the nozzle, wherein the bonding ink is composed of distilled water, glycerol and polyvinylpyrrolidone; the distri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com