A method for controlling the atmosphere in the sintering process of high frequency, wide temperature and low loss mnzn ferrite

A technology of sintering process and control method, applied in the direction of inductance/transformer/magnet manufacturing, electrical components, inorganic material magnetism, etc., can solve the problems of product cracking, multi-grain, defects, etc. The effect of improving high frequency magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

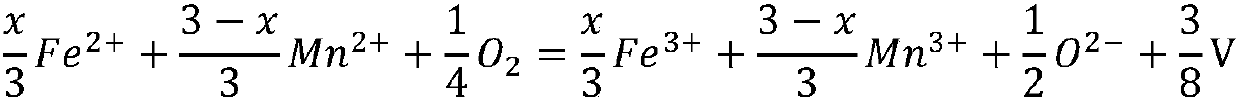

Method used

Image

Examples

Embodiment example 1

[0039] The content of the selected main components is calculated as oxides: Fe 2 o 3 : 71.2wt%, ZnO: 5.82wt%, MnO: the balance, the main component was ball milled for 1 hour, and the powder obtained from the first ball mill was heated to 930°C at a rate of 200-300°C / h in an air atmosphere , keep warm for 2 hours, and get a sintered powder with furnace cooling; add an appropriate amount of In to the black powder obtained by pre-sintering 2 o 3 , CoO, CaO, TiO 2 , SiO 2and other additives, and add an appropriate amount of deionized water, mill the second time for 4 hours to obtain powder particles with a particle size of 0.7-2 μm, and the particle size distribution obeys the normal distribution; dry the particles after the second ball milling, grind and disperse, add Polyvinyl alcohol is granulated, and sieved to obtain manganese-zinc-ferrite powder; the powder obtained by granulation is pressed into shape, and the green density should reach 2.6-3.6gcm -3 Put it into an atm...

Embodiment example 2

[0042] The content of the selected main components is calculated as oxides: Fe 2 o 3 : 71.64wt%, ZnO: 5.46wt%, MnO: the balance, the main component was ball milled for 1 hour, and the powder obtained by the first ball mill was heated to 930°C at a rate of 200-300°C / h in an air atmosphere , keep warm for 2 hours, and get a sintered powder with furnace cooling; add an appropriate amount of In to the black powder obtained by pre-sintering 2 o 3 , CoO, CaO, TiO 2 , SiO 2 and other additives, and add an appropriate amount of deionized water, mill the second time for 4 hours to obtain powder particles with a particle size of 0.7-2 μm, and the particle size distribution obeys the normal distribution; dry the particles after the second ball milling, grind and disperse, add Polyvinyl alcohol is granulated, and sieved to obtain manganese-zinc-ferrite powder; the powder obtained by granulation is pressed into shape, and the green density should reach 2.6-3.6g cm -3 Put it into an at...

Embodiment example 3

[0045] The content of the selected main components is calculated as oxides: Fe 2 o 3 : 71.07wt%, ZnO: 5.10wt%, MnO: the balance, the main component was ball milled for 1 hour, and the powder obtained from the first ball mill was heated to 930°C at a rate of 200-300°C / h in an air atmosphere , keep warm for 2 hours, and get a sintered powder with furnace cooling; add an appropriate amount of In to the black powder obtained by pre-sintering 2 o 3 , CoO, CaO, TiO 2 , SiO 2 and other additives, and add an appropriate amount of deionized water, mill the second time for 4 hours to obtain powder particles with a particle size of 0.7-2 μm, and the particle size distribution obeys the normal distribution; dry the particles after the second ball milling, grind and disperse, add Polyvinyl alcohol is granulated, and sieved to obtain manganese-zinc-ferrite powder; the powder obtained by granulation is pressed into shape, and the green density should reach 2.6-3.6g cm -3 Put it into an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com