Shield machine main bearing sealing grease and preparation method thereof

A technology for sealing grease and main bearings, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of extended construction period, loss of construction enterprises, damaged main bearings, etc., and achieves improved water erosion resistance, improved anti-emulsification, and good anti-emulsification sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

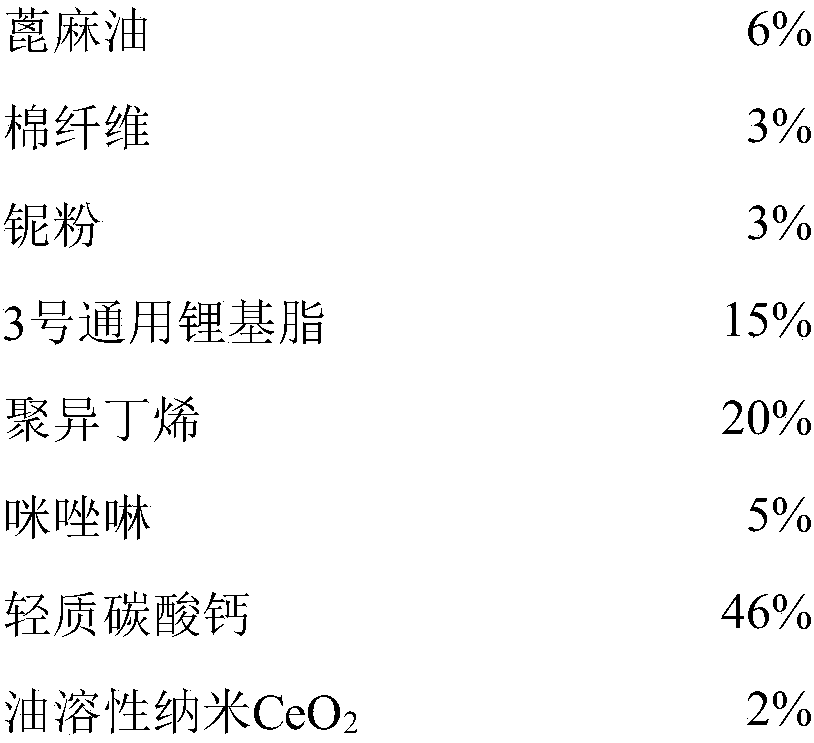

[0021] A shield machine main bearing sealing grease, its components and mass percentages are as follows:

[0022]

[0023] Preparation method: according to the above mass percentage, the oil-soluble nano-CeO 2 Add it into castor oil, stir for 1 hour at room temperature, then add niobium powder, No. 3 general-purpose lithium base grease, polyisobutylene, imidazoline, stir for 2 hours, then add cotton fiber material, stir for 2 hours, then add light calcium carbonate, and continue stirring 1h is enough.

Embodiment 2

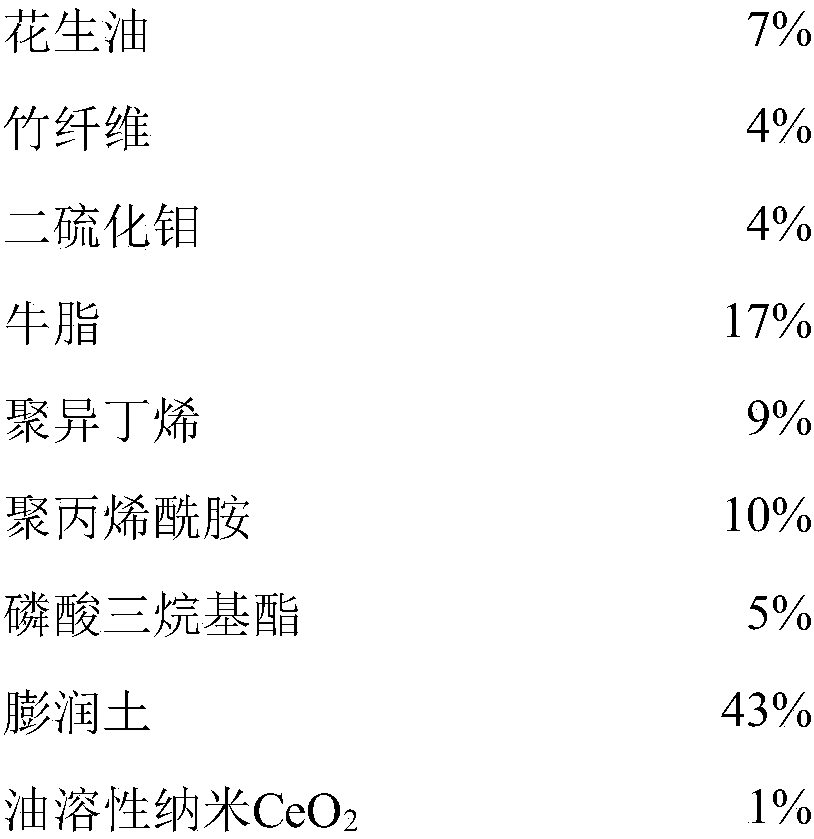

[0025] A shield machine main bearing sealing grease, its components and mass percentages are as follows:

[0026]

[0027] Preparation method: according to the above mass percentage, the oil-soluble nano-CeO 2 Add to peanut oil, stir for 1.5h, then add molybdenum disulfide, tallow, polyisobutylene, polyacrylamide, trialkyl phosphate, stir for 2.5h, then add bamboo fiber material, stir for 2.5h, then add bentonite, continue stirring 1.5h is enough.

Embodiment 3

[0029] A shield machine main bearing sealing grease, its components and mass percentages are as follows:

[0030]

[0031]

[0032] Preparation method: According to the above mass percentage, the oil-soluble nano-La 2 o 3 Add to soybean oil, stir for 2 hours, then add graphite, titanium-based grease, complex calcium sulfonate-based grease, ethylene propylene copolymer, 2,4,6-trimercapto-1,3,5-triazine, and stir for 3 hours , then add sepiolite fiber, stir for 3h, then add talcum powder, and continue stirring for 2h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com