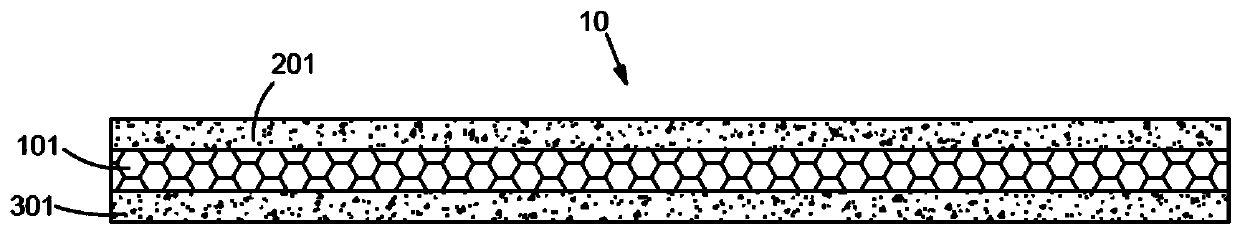

A kind of flexible heat dissipation film and its manufacturing method and composite flexible heat dissipation film

A heat-dissipating film and a technology for its production method are applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., which can solve the problems of unbendable tensile strength and easy breakage, and achieve good flexibility, The effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Material selection: The metal foam base material is nickel foam base material, which adopts a coil with a thickness of 1.0mm and a width of 200mm. %, bulk density is 0.45g / cm 3 The coating material is selected to contain 0.2% nano-copper, 0.3% acrylic resin binder, 1.5% graphene, and a modified graphene slurry composed of 98% solvent.

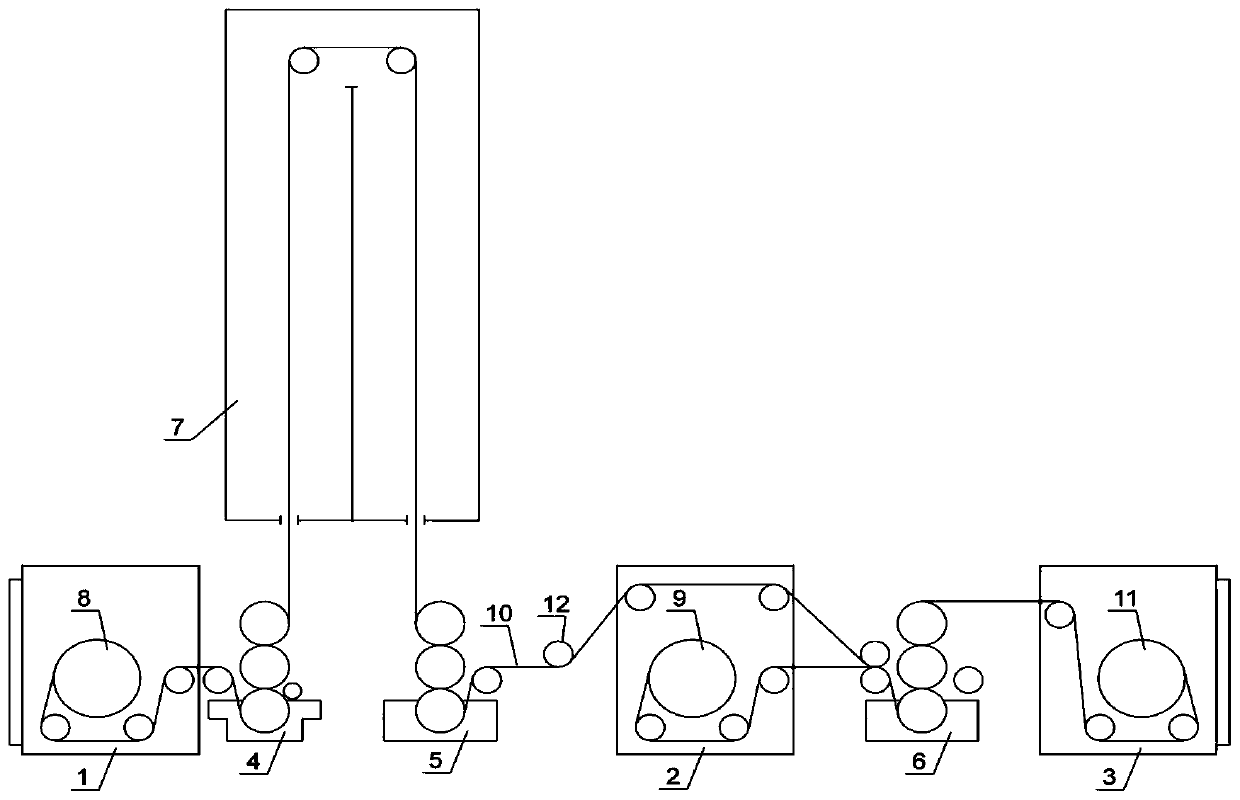

[0029] Use attached figure 2 The process shown produces a flexible heat dissipation film coil, wherein the coating material is coated on the surface of the substrate by dip coating. The specific production steps are as follows:

[0030] 1. System feed roller dip coating and low temperature vacuum drying

[0031] The foamed nickel substrate 8 enters the three-roll mixed dip coating system 4 through the substrate unwinding system 1 isotensively, and the surface of the foamed nickel substrate 8 is dip-coated with a coating containing 0.1% nano-copper-modified graphene slurry. material; and then dried by the low-temperature vacuum dryin...

Embodiment 2

[0036] Material selection: The metal foam base material is nickel foam base material, which adopts a coil with a thickness of 0.1mm and a width of 1800mm. %, bulk density is 0.5g / cm 3 ;Choose copper-modified graphene material and nickel electroplating solution for compounding, and the compounding content is controlled between 0.5% and 0.8%. The electroplating solution consists of: nickel sulfate 250g / L, nickel chloride 30g / L, boric acid 30g / L , copper modified graphene 0.55g / L, sodium lauryl sulfate 0.03g / L, 1,4-butynediol 0.8g / L, PH=5.0, T=45℃), dispersant (CMC) The mass concentration is 2g / L.

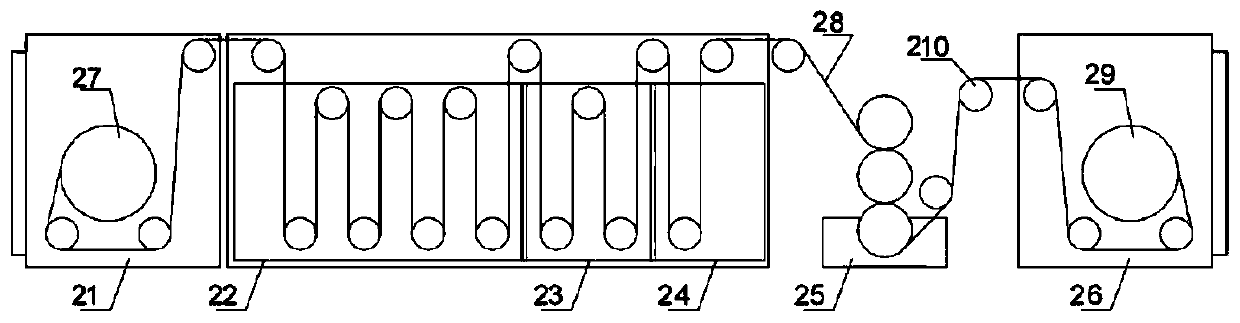

[0037] Use attached image 3 The shown process produces a flexible heat dissipation film coil, wherein the coating material is coated on the surface of the substrate by electroplating. The specific production steps are as follows:

[0038]1. System feed and process flow

[0039] The substrate 27 is isotonically introduced into the electroplating system 22 via the substrate unwind...

Embodiment 3

[0045] Material selection: Foam metal base material is copper foam base material, which adopts a coil with a thickness of 1.0mm and a width of 200mm. %, bulk density is 0.45g / cm 3 ; Coating material selection containing 0.1% nano-copper modified graphene slurry.

[0046] Use attached Figure 4 The process shown produces a flexible heat dissipation film coil, wherein the coating material is coated on the surface of the substrate by dip coating. The specific production steps are as follows:

[0047] 1. System feeding and high vacuum

[0048] The foamed copper substrate 38 enters the three-roller mixed dip coating system 32 through the substrate unwinding system 31 isotensively, and the surface of the foamed nickel substrate 38 is dip-coated with a coating containing 0.1% nano-copper modified graphene slurry. Material 37; then dried by a low-temperature vacuum drying system 35 to obtain an orderly arranged nanometer-sized network three-dimensional structure layer, wherein the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com