Porcine feed additive capable of promoting growth and improving meat quality and preparation method of porcine feed additive

A feed additive and raw material technology, applied in the field of animal husbandry, can solve the problems of no improvement in pork quality, harm to eating people, and decreased appetite of pigs, so as to increase pork flavor, reduce feed-to-meat ratio, and increase protein content and intramuscular fat content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

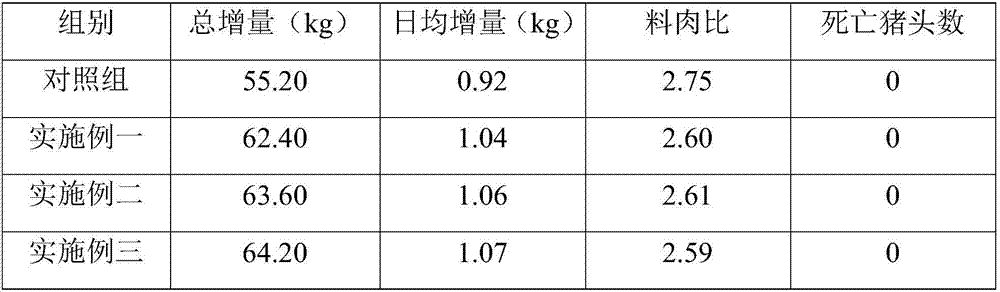

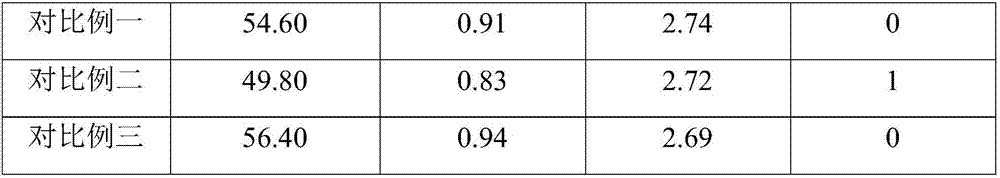

Examples

Embodiment 1

[0022] This embodiment provides a feed additive for pigs. The raw material components are calculated in parts by weight, including: 3 parts by weight of multivitamins, 4 parts by weight of compound amino acid preparations, 2 parts by weight of compound enzyme preparations, 15 parts by weight of fermentation powder and 4 parts by weight of plant extracts. parts by weight.

[0023] Wherein, the raw material components of the multivitamin include: 4 parts of vitamin A, 2 parts of vitamin B2, 3 parts of vitamin E, 8 parts of folic acid, 10 parts of vitamin C and 8 parts of biotin in parts by weight.

[0024] The raw material components of the compound amino acid include, in parts by weight, 5 parts of lysine, 3 parts of methionine, 4 parts of threonine, 2 parts of tryptophan and 6 parts of arginine.

[0025] The raw material components of the compound enzyme preparation include: 6 parts of lipase, 7 parts of maltase, 1 part of xylanase, 4 parts of beta-glucanase and 3 parts of pro...

Embodiment 2

[0034] This embodiment provides a feed additive for pigs. The raw material components are calculated in parts by weight, including: 5 parts by weight of compound vitamins, 2 parts by weight of compound amino acid preparations, 3 parts by weight of compound enzyme preparations, 10 parts by weight of fermentation powder and 5 parts by weight of plant extracts. parts by weight.

[0035] Wherein, the raw material components of the multivitamin include: 8 parts of vitamin A, 1 part of vitamin B2, 5 parts of vitamin E, 6 parts of folic acid, 12 parts of vitamin C and 6 parts of biotin in parts by weight.

[0036] The raw material components of the compound amino acid include, in parts by weight, 8 parts of lysine, 2 parts of methionine, 6 parts of threonine, 1 part of tryptophan and 8 parts of arginine.

[0037] The raw material components of the compound enzyme preparation include: 10 parts of lipase, 5 parts of maltase, 3 parts of xylanase, 2 parts of beta-glucanase and 5 parts of...

Embodiment 3

[0046] This embodiment provides a feed additive for pigs. The raw material components are calculated in parts by weight, including: 4 parts by weight of compound vitamins, 3 parts by weight of compound amino acid preparations, 2.5 parts by weight of compound enzyme preparations, 12 parts by weight of fermentation powder and 4.5 parts by weight of plant extracts. parts by weight.

[0047] Wherein, the raw material components of the multivitamin include: 6 parts of vitamin A, 1.5 parts of vitamin B2, 4 parts of vitamin E, 7 parts of folic acid, 11 parts of vitamin C and 7 parts of biotin in parts by weight.

[0048] The raw material components of the compound amino acid include, in parts by weight, 6 parts of lysine, 2.5 parts of methionine, 5 parts of threonine, 1.5 parts of tryptophan and 7 parts of arginine.

[0049] The raw material components of the compound enzyme preparation include: 8 parts of lipase, 6 parts of maltase, 2 parts of xylanase, 3 parts of beta-glucanase and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com