Soluble microneedle patch containing purified protein derivatives of tuberculin, and preparation method of soluble microneedle patch

A technology for tuberculin and protein derivatives, which is applied in the field of soluble microneedle patches loaded with pure protein derivatives of tuberculin and its preparation, which can solve the problem of high dissolution rate, poor rigidity, and high dissolution rate. Slowness and other problems, to achieve good skin puncture strength, conducive to popularization and use, and good compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The soluble microneedle patch loaded with tuberculin pure protein derivative provided in this example was prepared by the following method:

[0055] (1) Preparation of needle solution: Accurately weigh 0.25 g of sodium hyaluronate with an average molecular weight of 8,000, 0.3 g of hydroxyethyl starch with an average molecular weight of 40,000, 0.1 g of polyvinylpyrrolidone with an average molecular weight of 12,000, 0.1 g of glucosamine, Amino acid 0.03g, sodium dihydrogen phosphate 10mg, 300ug / ml tuberculin pure protein derivative water solution for injection 2.0ml, mix, dissolve and swell.

[0056] (2) Preparation of flexible base layer solution: Accurately weigh 8.0 g of hydroxypropyl methylcellulose (the viscosity of 10% aqueous solution is 5 mPa.s), 15.0 g of hydroxypropyl cellulose (the viscosity of 10% aqueous solution is 300 mPa.s), .s), 0.30g of sodium hyaluronate with an average molecular weight of 4 million, 80g of water for injection, vortex, mix evenly, an...

Embodiment 2

[0061] The soluble microneedle patch loaded with tuberculin pure protein derivative provided in this example was prepared by the following method:

[0062] (1) Preparation of needle solution: Accurately weigh 0.3 g of sodium hyaluronate with an average molecular weight of 8,000, 0.15 g of hydroxyethyl starch with an average molecular weight of 20,000, 0.15 g of polyvinylpyrrolidone with an average molecular weight of 30,000, glutamic acid 0.15 g, 8 mg of sodium dihydrogen phosphate, 2.0 ml of aqueous solution of water for injection of tuberculin pure protein derivatives at 600 ug / ml, mix, dissolve and swell.

[0063] (2) Preparation of flexible base layer solution: Accurately weigh 20.0 g of hydroxypropyl methylcellulose (the viscosity of a 10 wt % aqueous solution is 5 mPa.s), 1.0 g of sodium hyaluronate with an average molecular weight of 2 million, and water for injection 80g, vortex, mix well and dissolve.

[0064] (3) Preparation of soluble microneedle patch loaded with ...

Embodiment 3

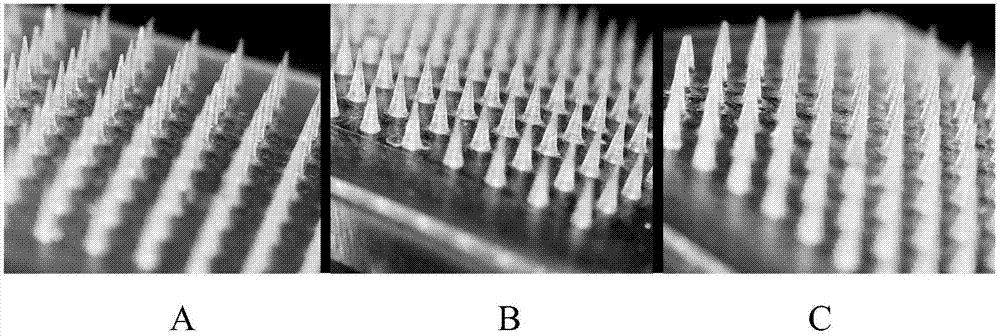

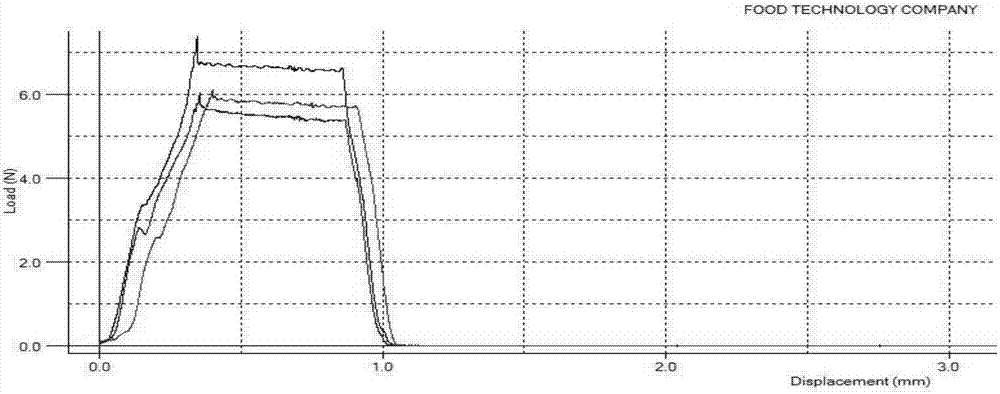

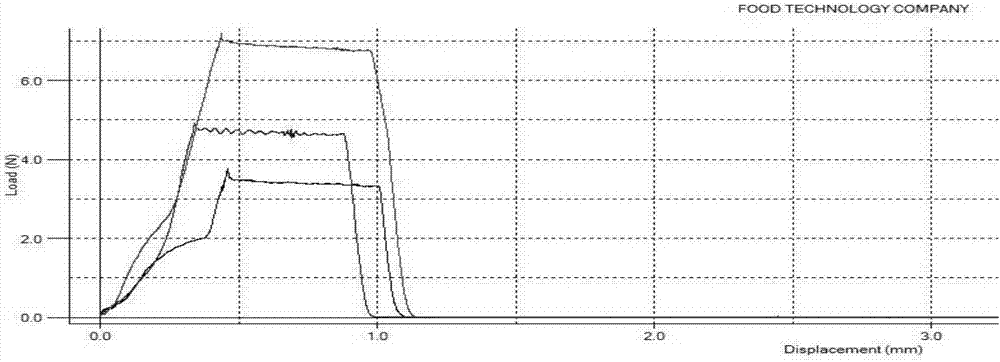

[0074] For the soluble microneedles prepared in Example 1-2 and Comparative Example 1, compare the hardness, puncture property and solubility of the microneedles, and the specific evaluation and comparison methods are as follows:

[0075] (1) Microneedle hardness test

[0076] The prepared microneedle patch was cut into a 10×10 array patch (100 needles), and the needle tip was placed on the horizontal test platform of the TMS-PRO food property analyzer of the FTC company in the United States, and passed through the P / 6 flat-head stainless steel Cylindrical probe, at a stable speed of 0.1mm / sec, excitation force 0.05N, apply axial vertical force, set measurement parameters, probe descending speed 10mm / min, probe compression speed, probe lifting speed, compression 90%, acquisition Rate 200pps / s. The analyzer records the mechanical changes during the probe contact with the needle tip until reaching the preset compression amount (microneedle height 400 μm). After the test is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com