Manufacturing method and application of alveolate blind hole toughened zirconium oxide ceramic shell

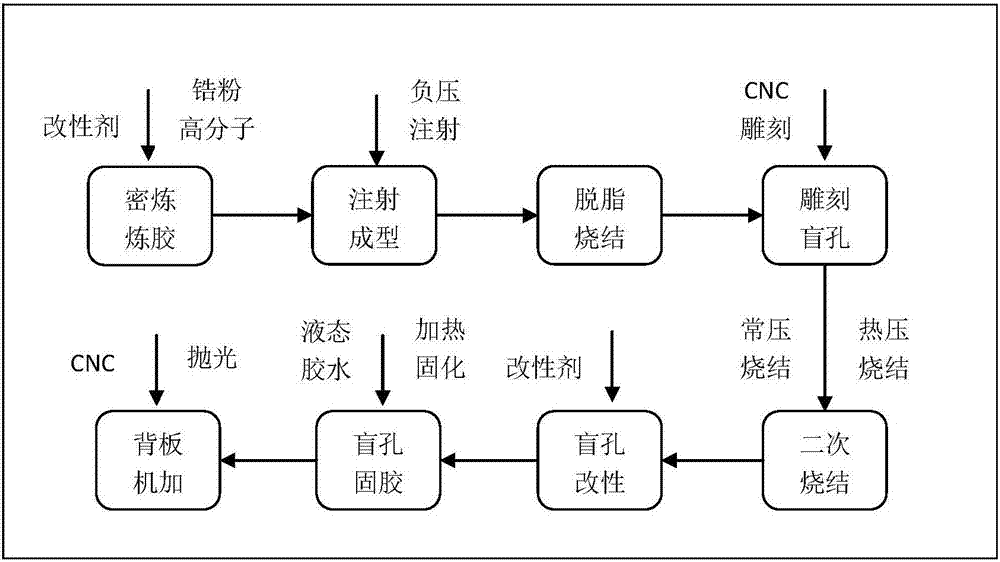

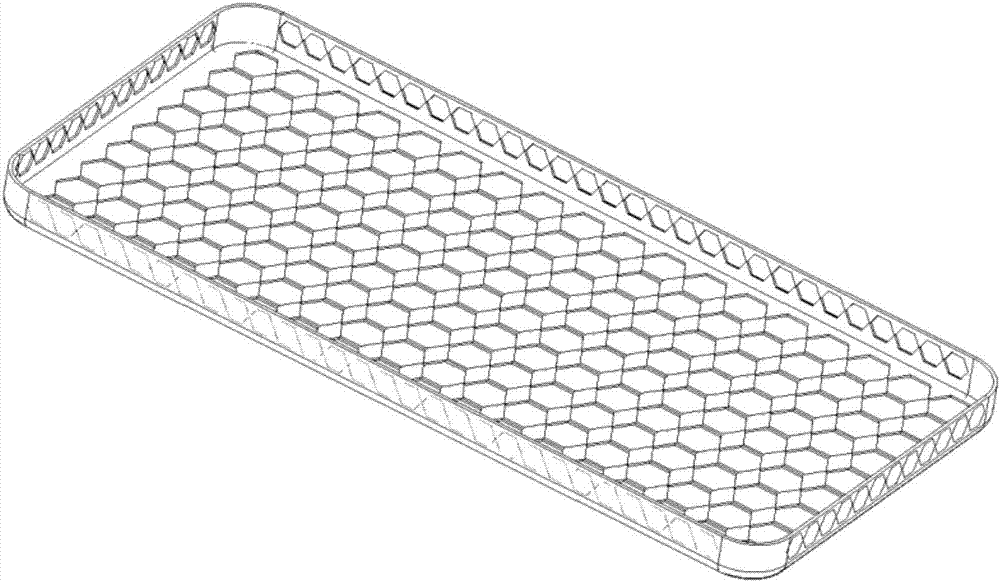

A technology of zirconia ceramics and a manufacturing method, which is applied to the structure of telephones and other directions, can solve the problems of inconsistent development paths of light and thin electronic products, cumbersome zirconia ceramic backplanes, poor anti-drop performance, etc., and achieve high processing efficiency and cost advantages. , Conducive to the development of light and thin, and the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh 14g of γ-(methacryloyloxy)propyltrimethoxysilane, 1.706kg of 3Y-TZP ceramic powder with a D50 of 30nm, 180g of No. 58 paraffin and 100g of polypropylene, and add the weighed organic matter into a 3L Heat up the internal mixer to 130°C to melt it, then add the ceramic powder into the internal mixing in 3 times, after the ceramic powder is added, pump the negative pressure of the internal mixer to -0.05MPa, and internally mix at 135°C for 3 hours get fed. Put the feed into the hopper of the injection molding machine, put the 2.15-inch watch case mold cavity into the injection molding machine, pump the 2.15-inch watch case mold cavity to -0.08MPa, set the barrel temperature of the injection molding machine to 145°C, and inject The pressure is 180MPa for injection molding, so that the molten feeding material is injected into the mold cavity at high speed and kept under pressure for 4 seconds to obtain the watch case back plate blank.

[0040] Palletize the watch case...

Embodiment 2

[0046] Weigh 16g of ammonium stearate, 1.704kg of 3Y-TZP ceramic powder with a D50 of 30nm, 180g of No. 56 paraffin and 100g of polyethylene, add the weighed organic matter into a 3L internal mixer and heat up to 115°C to melt it. Then add the ceramic powder into the internal mixing in 3 times. After the ceramic powder is added, the negative pressure of the internal mixer is pumped to -0.05MPa, and the internal mixing is carried out at 120°C for 4 hours to obtain the feed. Put the feed material into the hopper of the injection molding machine, put the cavity of the mobile phone mold with a thickness of 5 inches into the injection molding machine, pump the cavity of the 5-inch mobile phone mold to -0.09MPa, set the temperature of the barrel of the injection molding machine to 130°C, and inject The pressure is 250MPa for injection molding, so that the molten feed material is injected into the mold cavity at high speed and kept under pressure for 3 seconds to obtain the mobile pho...

Embodiment 3

[0053] Weigh 10g of stearic acid, 1.85kg of 3Y-TZP ceramic powder with a D50 of 200nm, 80g of No. 58 paraffin and 60g of polyphenylene sulfide, add the weighed organic matter into a 3L internal mixer and heat up to 120°C to melt it , and then add the ceramic powder into the internal mixing in 3 times. After the ceramic powder is added, the negative pressure of the internal mixer is pumped to -0.08MPa, and the internal mixing is carried out at 150°C for 1 hour to obtain the feed. Put the feed into the hopper of the injection molding machine, put the 8-inch flat mold cavity into the injection molding machine, pump the 8-inch flat mold cavity to -0.07MPa, set the barrel temperature of the injection molding machine to 155°C, and the injection pressure For 200MPa injection molding, the molten feed material is injected into the mold cavity at high speed and kept under pressure for 5 seconds to obtain a flat shell blank.

[0054] Palletize the flat shell blanks into the degreasing fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com