Method used for leaching antimony and manganese simultaneously from stibnite and pyrolusite

A technology of stibnite and pyrolusite, which is applied in the field of metallurgy and chemical industry, can solve the problems of large amount of slag, affecting manganese recovery rate, low reduction rate and leaching rate, etc., achieve high leaching rate of antimony and manganese, avoid poor production environment, and reduce resource consumption. The effect of high comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

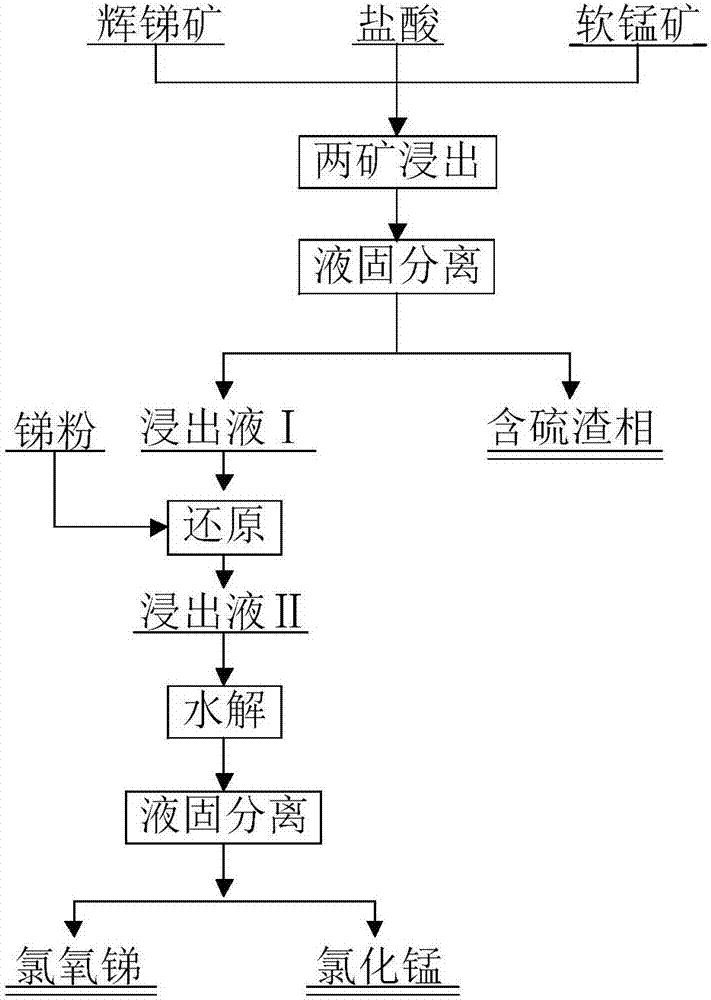

[0045] a kind of like figure 1 The method for simultaneously leaching antimony and manganese from stibnite and pyrolusite of the present invention as shown, specifically comprises the following steps:

[0046] (1) With antimony mass fraction of 42% stibnite, containing MnO 2 The pyrolusite with a mass fraction of 38.18% is the raw material, and the main component of the stibnite is Sb 2 S 3 .

[0047] (2) Configure 500mL of 4mol / L hydrochloric acid, heat the hydrochloric acid to 70 degrees, use the crushed stibnite and pyrolusite with a particle size of 180-250 mesh as raw materials, and weigh it according to Mn / S (molar ratio) 1.2 / 1 After measuring well, add it to the reaction tank filled with hydrochloric acid. The volume of hydrochloric acid is measured according to the liquid-solid ratio (mL / g) of 5 / 1. Stir to make the stibnite and pyrolusite evenly distribute and fully react in hydrochloric acid.

[0048] (3) During the leaching process, the rotational speed is contr...

Embodiment 2

[0053] (1) With antimony mass fraction of 42% stibnite, containing MnO 2 The pyrolusite with a mass fraction of 38.18% is the raw material, and the main component of the stibnite is Sb 2 S 3 .

[0054] (2) Configure 500mL of 5mol / L hydrochloric acid, heat the hydrochloric acid to 80 degrees, weigh the broken particles with a particle size of 180-250 mesh according to the Mn / S (mole) of 1.2 / 1, and add it to a container filled with hydrochloric acid In the reaction tank, the volume of hydrochloric acid is measured as 7 / 1 according to the liquid-solid ratio (mL / g). Stir to make the stibnite and pyrolusite evenly distribute and fully react in hydrochloric acid.

[0055] (3) During the leaching process, the rotational speed is controlled at 500r / min, and the leaching time is 4h.

[0056] (4) After the leaching process, the obtained pulp is filtered while hot at the leaching temperature to obtain a solution mainly composed of antimony chloride and manganese chloride and a slag p...

Embodiment 3

[0060] (1) With antimony mass fraction of 42% stibnite, containing MnO 2 The pyrolusite with a mass fraction of 38.18% is the raw material, and the main component of the stibnite is Sb 2 S 3 .

[0061] (2) Configure 500mL of 5mol / L hydrochloric acid, heat the hydrochloric acid to 90 degrees, weigh the broken particles with a particle size of 180-250 mesh according to the Mn / S (mole) of 1.4 / 1, and add it to a container filled with hydrochloric acid In the reaction tank, the volume of hydrochloric acid is measured as 10 / 1 according to the liquid-solid ratio (mL / g). Stir to make the stibnite and pyrolusite evenly distribute and fully react in hydrochloric acid.

[0062] (3) During the leaching process, the rotational speed is controlled at 600r / min, and the leaching time is 5h.

[0063] (4) After the leaching process, the obtained pulp is filtered while hot at the leaching temperature to obtain a solution mainly composed of antimony chloride and manganese chloride and a slag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com