Gradient transition layer for metal-based thin film sensor and preparation method thereof

A thin-film sensor and transition layer technology, which is applied in metal material coating process, coating, vacuum evaporation plating, etc., can solve problems affecting service life, cracks and cracks, etc., to avoid excessive oxidation, release internal stress, avoid The effect of micro-cracks or even cracking and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a gradient transition layer for a metal-based film sensor, such as figure 2 As shown, it includes a three-layer structure, from bottom to top are NiCrAlY alloy layer, NiCrAlY alloy and Al 2 o 3 Gradient layer, Al 2 o 3 layer; thin-film sensors based on this graded transition layer include a five-layer structure, such as image 3 As shown, from bottom to top are nickel base alloy substrate 1, gradient transition layer 2, Al 2 o 3 Ceramic insulating layer 3, sensitive functional layer 4 and Al 2 o 3 protective layer5. The preparation method of this film sensor comprises the following steps:

[0027] Step 1. Surface treatment of the Ni-based alloy substrate: first, polish the surface of the alloy substrate, then use industrial degreaser, acetone, alcohol and deionized water to ultrasonically clean the alloy substrate successively, dry it with a nitrogen gun, and place it in an oven Dry in medium, and use plasma to clean the substrate before ...

Embodiment

[0037] In this embodiment, the nickel-based alloy plate is used as the alloy substrate to be tested, and the process of preparing the gradient transition layer of the present invention thereon includes the following steps:

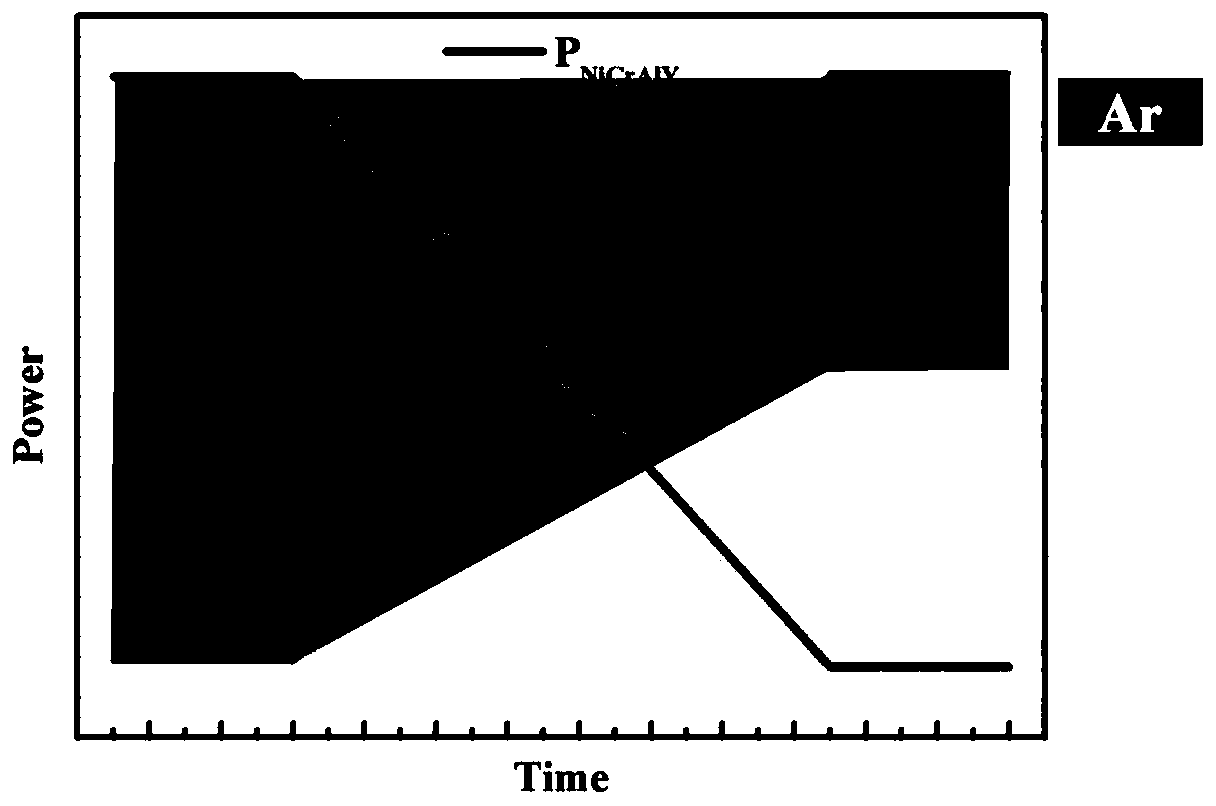

[0038] Step 1. Preparation of NiCrAlY alloy layer: Put the polished and cleaned nickel-based alloy substrate on the back and the vacuum degree is 8.0×10 -4 In a vacuum environment of Pa, argon gas with a purity of 99.999% (volume percentage) is introduced as the sputtering medium, and NiCrAlY alloy is used as the target material, at a sputtering pressure of 0.4Pa, a sputtering power of 200W, and a substrate temperature of 500°C Under the condition of , the NiCrAlY alloy was deposited on the cleaned nickel-based alloy substrate by DC sputtering method, and the thickness of the deposited film was 10 μm;

[0039] Step 2. NiCrAlY Alloy and Al 2 o 3 Preparation of the gradient layer: After the NiCrAlY alloy layer with a thickness of 10 μm is prepared in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com