Preparation method of hybrid silicon film with hydrophilically modified surface

A hybrid silicon membrane and hydrophilic modification technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of weak surface hydrophilicity, achieve convenient post-processing, and avoid pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

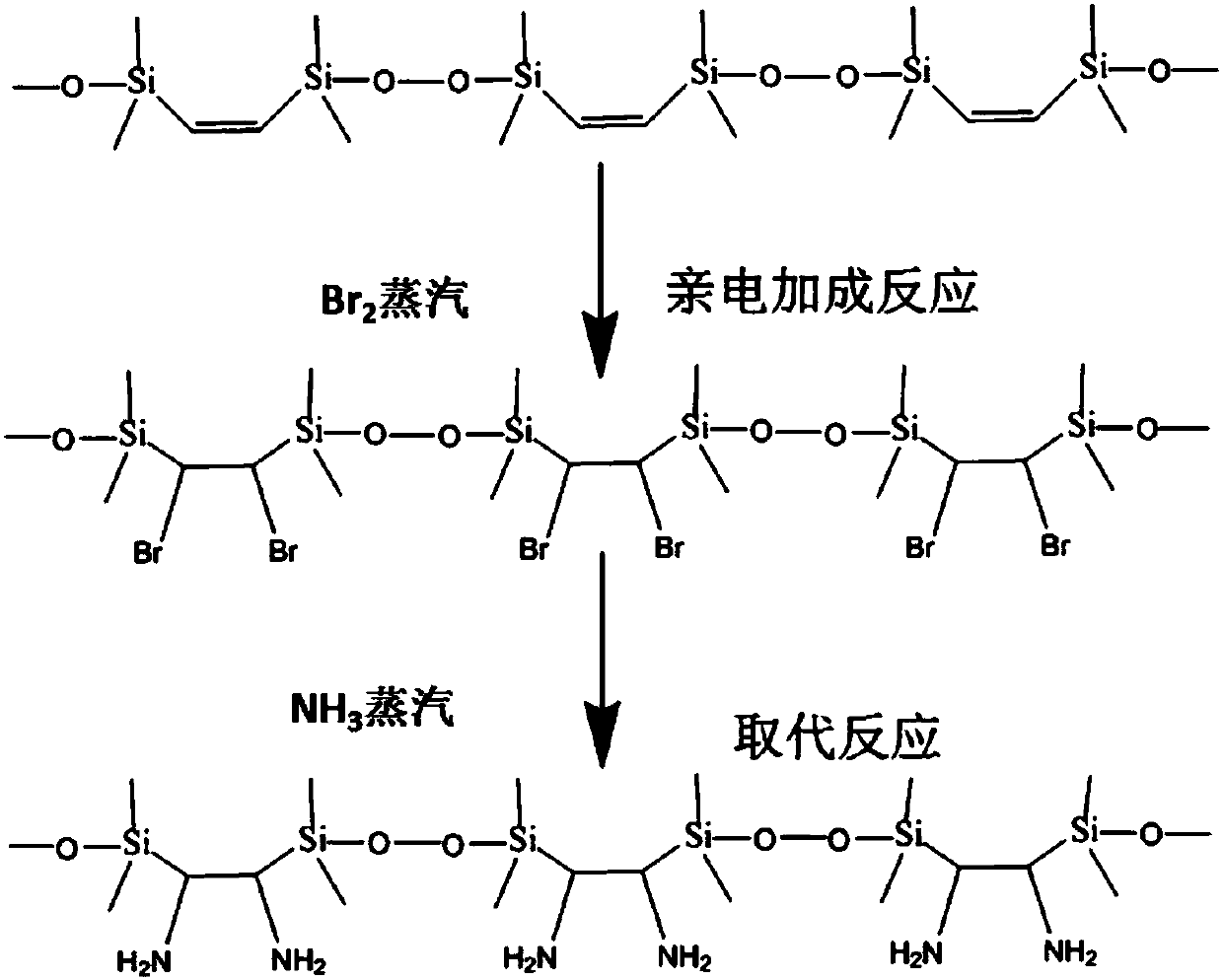

Method used

Image

Examples

Embodiment 1

[0026] (1) Put a beaker and a watch glass in the vacuum drying dish, put excess liquid bromine in the beaker, put into the watch glass by 1,2-bis(triethoxysilyl) ethylene sol to prepare the separation layer Hybrid silicon membrane, the hybrid silicon membrane is not in direct contact with liquid bromine,

[0027] Exhaust the vacuum drying dish, and control the pressure down to 3kPa at room temperature (25°C, the same below) to allow the bromine vapor to react with the hybrid silicon film;

[0028] (2) Evacuation step (1) The liquid bromine vapor in the vacuum drying dish, take out the hybrid silicon film, and carry out vacuum heating and drying at 100° C. for 12 hours at 0.0133 Pa;

[0029] (3) Put the hybrid silicon film dried in step (2) into a vacuum drying dish containing excess ammonia water in the same non-contact manner, and then also exhaust the vacuum drying dish at room temperature (25°C, the same below). Control the pressure down to 80kPa to fully react the hybrid ...

Embodiment 2

[0031] (1) with embodiment 1;

[0032] (2) with embodiment 1;

[0033] (3) Immerse the hybrid silicon membrane dried in step (2) into excess ethylenediamine solution, take out the hybrid silicon membrane after fully reacting, wash it with absolute ethanol for 3 times, and then put it into a 60°C vacuum drying oven save in .

Embodiment 3

[0035] (1) First, immerse the raw material hybrid silicon membrane consistent with step (1) of Example 1 into anhydrous acetonitrile containing excess sodium hydroxide solution, and after cooling to -5°C in an ice-water bath, add excess tert-butyl peroxide Oxidize the hydrogen solution and stir it sufficiently to cause an epoxidation reaction;

[0036] (2) Wash the membrane prepared in step (1) fully with absolute ethanol, dry it and put in excess NaHSO 3 / Na 2 SO 3 solution, fully stirred at 40°C for ring-opening sulfonation reaction, then washed with a large amount of distilled water, and then stored in a 60°C drying oven.

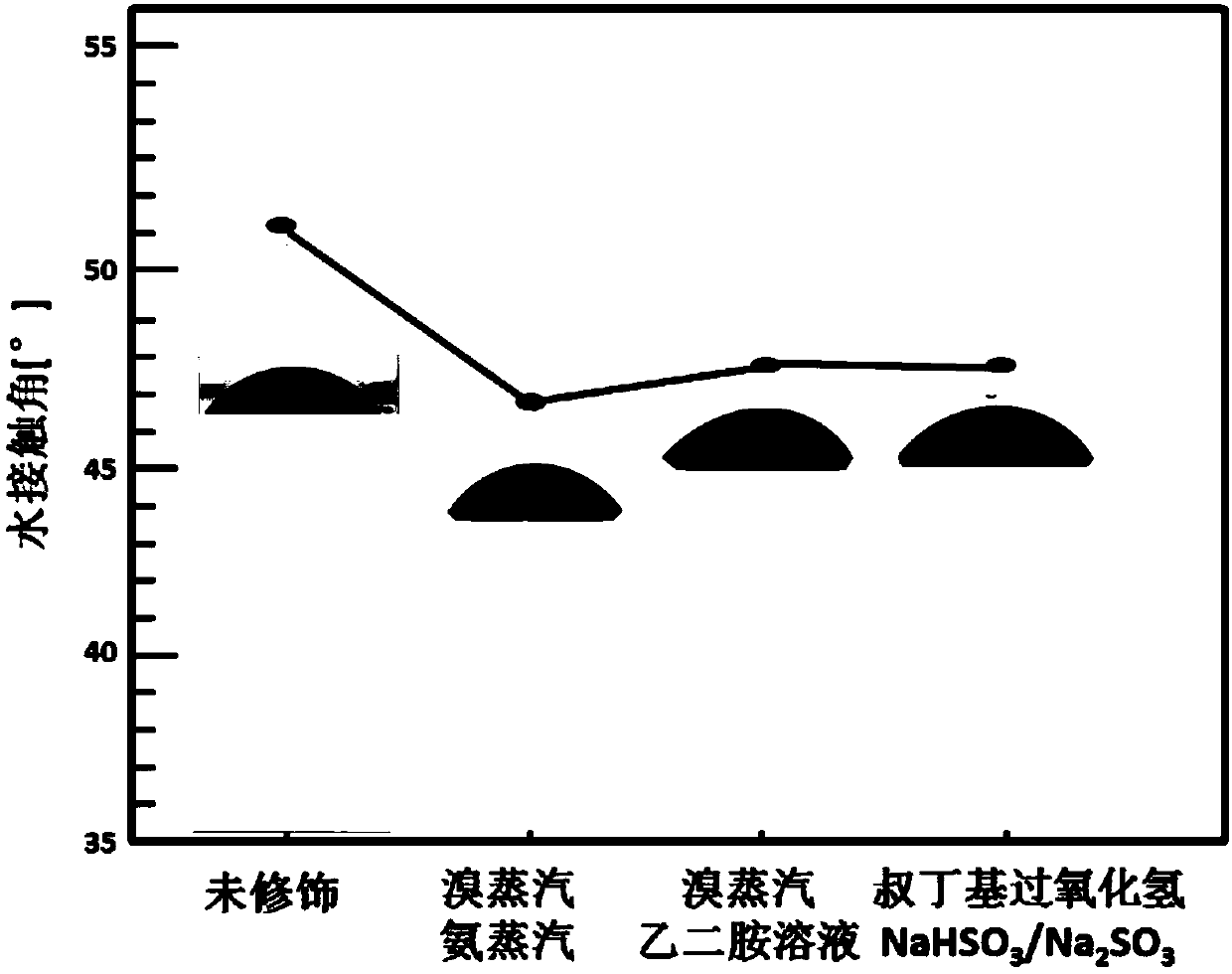

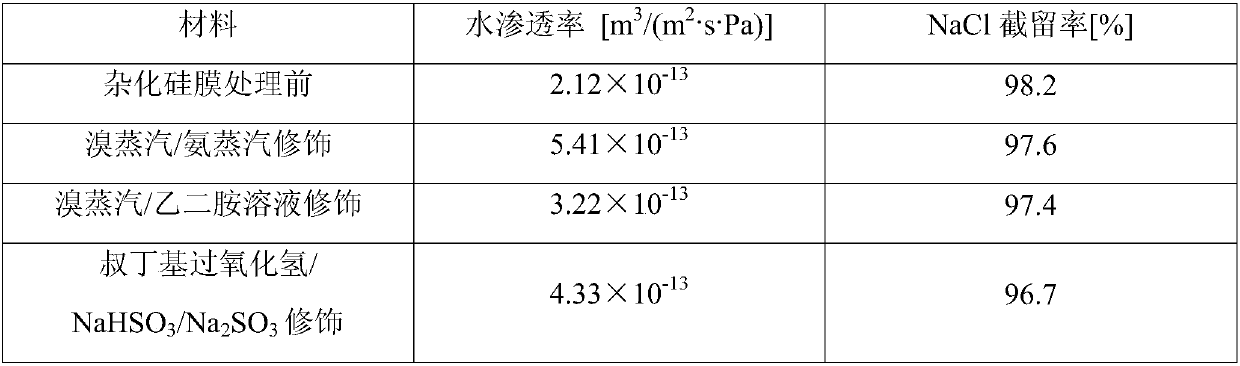

[0037] Table 1 is before hybrid silicon membrane treatment in embodiment 1 and with bromine vapor / ammonia vapor (embodiment 1), bromine vapor / ethylenediamine solution (embodiment 2) and tert-butyl hydroperoxide / NaHSO 3 / Na 2 SO 3 After the solution (embodiment 3) was processed, in the reverse osmosis experiment, the contrast of permeability and NaCl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com