Method for preparing layered ceramic tool based on shock wave conduction theory

A ceramic cutting tool and shock wave technology, applied in the field of layered ceramic cutting tool preparation based on shock wave conduction theory, can solve problems such as collapse, and achieve the effects of small friction factor, good comprehensive mechanical properties, and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

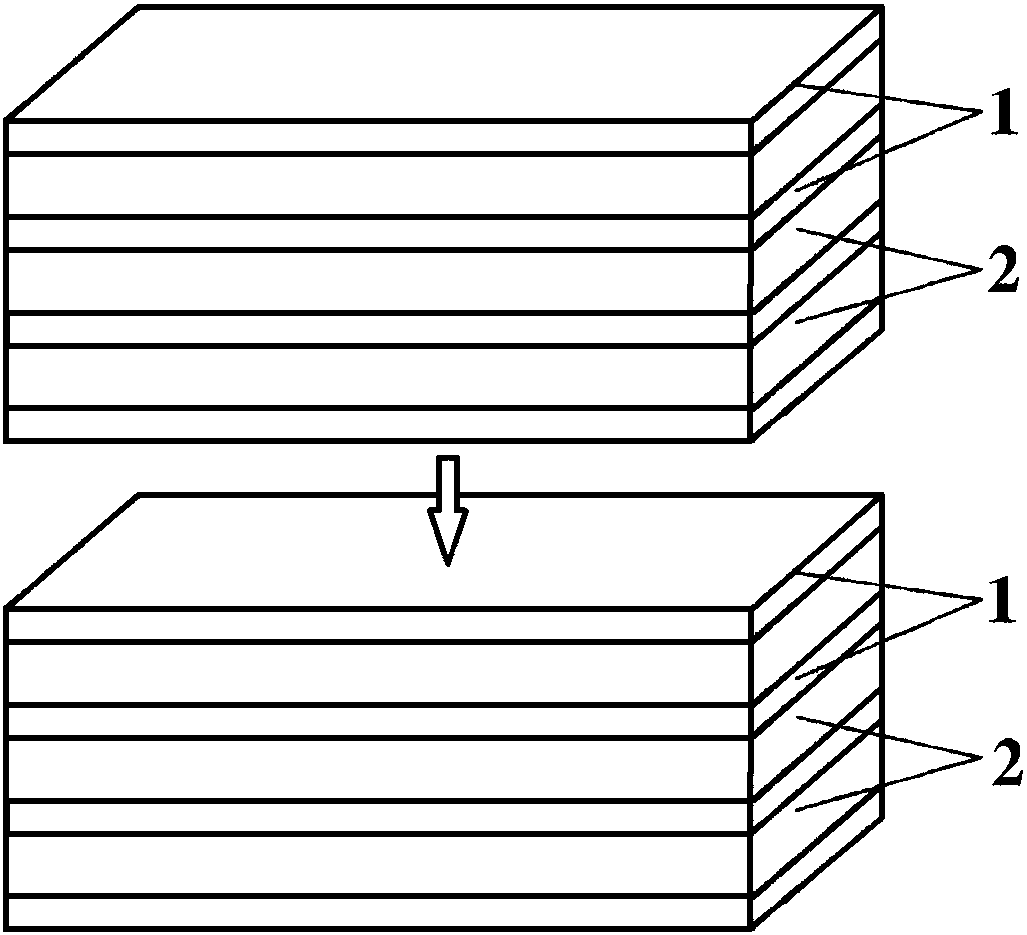

[0016] Example 1: According to Al 2 O 3 80%, TiB 2 The mass ratio of 19% to MgO 1% is weighed as the micro-laminated material (1), Al 2 O 3 The mass ratio of 35% and WC-Co 65% is used to weigh the material of the base layer (2); the weighed mixed powders are respectively milled with deionized water as the medium and alumina as the grinding ball by planetary intensified ball milling for 150 h. Dry in a vacuum drying oven and pass the mixed powder through a 200-mesh sieve. Calculate the mass of each base layer (2) and the micro-laminated layer (1) according to the mixed theoretical density, layer thickness, and inner diameter of the graphite mold of the micro-laminated layer (1) and the base layer (2), and use a powder press Press the base layer (2) and the micro-laminated layer (1) into pieces, according to figure 1 The stacking sequence shown is placed in a graphite mold for hot-press sintering in vacuum, the number of layers is 21; the sintering temperature is 1650℃, the sinte...

Embodiment 2

[0017] Embodiment 2: Others are the same as embodiment 1, the difference is that according to Al 2 O 3 78%, TiB 2 The mass ratio of 20% to MgO2% is weighed as the micro-laminated material (1), Al 2 O 3 The mass ratio of 40% and WC-Co 60% is used to weigh the material of the base layer (2); the sintering temperature is 1620℃, the sintering pressure is 35MPa, and the sintering holding time is 25min; the vickers hardness of the sintered layered ceramic tool material is 18.8~19.7GPa, Frontal equivalent bending strength 850~970MPa, fracture toughness 7.8~8.2MPa·m 1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com