A kind of brazing auxiliary agent for tungsten steel plane welding and its welding method

A technology of plane welding and welding method, which is applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., which can solve the problems of poor weldability and easy seam retention of tungsten carbide, so as to improve welding efficiency and desoldering Less, avoid the effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

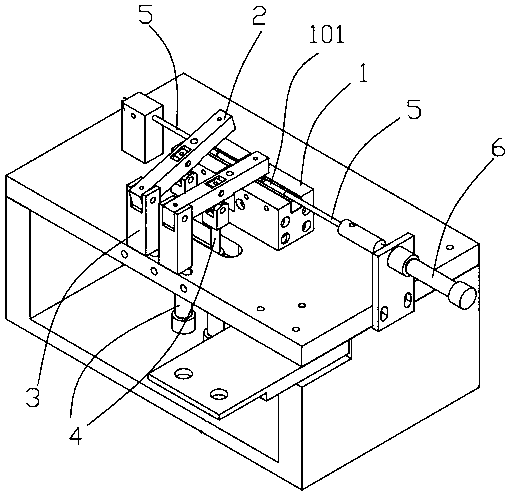

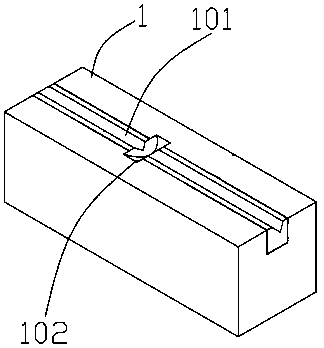

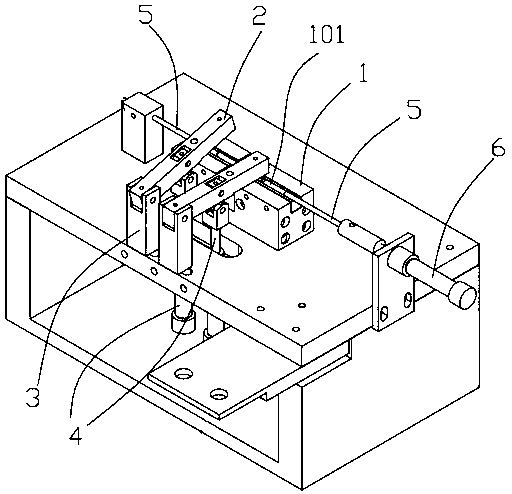

Image

Examples

Embodiment 1

[0027] This embodiment provides a kind of brazing flux for tungsten steel plane welding, including the following components by weight: KF: 48 parts, B 2 O 3 : 20 parts, CoCl 2 : 10 parts, complex fluoroborate: 8 parts, complex borate: 10 parts, surfactant: 6 parts, water: 63 parts. Among them, the compound fluoroborate is a mixture of potassium fluoroborate and ammonium fluoroborate in a mass ratio of 2:1, the compound borate is a mixture of sodium borate and potassium borate in a mass ratio of 1:1, and the surfactant is perfluoroalkane base quaternary ammonium salt. Put the above-mentioned components into a crucible according to the proportion and mix them evenly, boil them at a temperature of 150-180°C for 20 minutes, remove the moisture, and form a paste.

[0028] The brazing additive prepared in this example is evenly mixed, without delamination and no inclusions visible to the naked eye, and the brazing additive has good spreadability on the solid silver solder sheet. ...

Embodiment 2

[0037] This embodiment provides a kind of brazing flux for tungsten steel plane welding, including the following components by weight: KF: 45 parts, B 2 o 3 : 15 parts, CoCl 2 : 12 parts, complex fluoroborate: 10 parts, complex borate: 12 parts, surfactant: 9 parts, water: 52 parts. Among them, the compound fluoroborate is a mixture of potassium fluoroborate and ammonium fluoroborate in a mass ratio of 3:1, the compound borate is a mixture of sodium borate and potassium borate in a mass ratio of 1:1, and the surfactant is perfluoroalkane base amine. Put the above-mentioned components into a crucible according to the proportion and mix them evenly, boil them at a temperature of 150-180°C for 15 minutes, remove the moisture, and form a paste.

[0038] The brazing additive prepared in this example is evenly mixed, without delamination and no inclusions visible to the naked eye, and the brazing additive has good spreadability on the solid silver solder sheet.

[0039] The meth...

Embodiment 3

[0041] This embodiment provides a kind of brazing flux for tungsten steel plane welding, including the following components by weight: KF: 50 parts, B 2 o 3 : 23 parts, CoCl 2 : 12 parts, complex fluoroborate: 8 parts, complex borate: 7 parts, surfactant: 4 parts, water: 68 parts. Among them, the compound fluoroborate is a mixture of potassium fluoroborate and ammonium fluoroborate in a mass ratio of 2:1, the compound borate is a mixture of sodium borate and potassium borate in a mass ratio of 1:1, and the surfactant is perfluoroalkane base amine. Put the above components into a crucible according to the proportion and mix them evenly, boil them at a temperature of 150-180°C for 23 minutes, remove the moisture, and form a paste.

[0042] The brazing additive prepared in this example is evenly mixed, without delamination and no inclusions visible to the naked eye, and the brazing additive has good spreadability on the solid silver solder sheet.

[0043] The method for weldi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com