Method of preparing solid-solid phase change material through grafting copolymerization

A phase-change material and phase-change material technology, applied in the field of functional materials, can solve problems such as leakage, and achieve the effects of wide application range, improved heat resistance and processing function, and improved heat resistance and processing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Dry the porous silicon dioxide raw material, and then ultrasonically disperse it into acetic acid for acid treatment, and dry it before use; use silica gel to dry PEG-6000 before use. Take 60g of acid-treated porous silica and add it to a three-necked flask filled with 200ml of distilled water, stir and disperse evenly, heat the dried PEG-6000 to a molten state, and pour it into the three-necked flask at a stirring speed of 1000r / min Add 30g of molten PEG-6000 dropwise while stirring, continue stirring for 0.5h, then add 5g of toluene diisocyanate and 0.2g of stannous octoate, and then place the three-necked flask in a constant temperature water bath equipped with a condenser tube and a stirrer. The temperature of the constant temperature water bath was controlled to 70° C., and the reaction was carried out under reflux for 2 hours to obtain a crude product. Centrifuge the crude product with a centrifuge, control the speed of the centrifuge to 6000r / min, and the centrif...

Embodiment 2

[0036] The porous silicon dioxide raw material is dried, then ultrasonically dispersed in acetic acid for acid treatment, and then dried for use; the PEG-1000 is dried for use after being dried with silica gel. Take 70g of acid-treated porous silica and add it to a three-necked flask filled with 200ml of distilled water, stir and disperse evenly, heat the dried PEG-1000 to a molten state, and pour it into the three-necked flask at a stirring speed of 500r / min Add 40g of molten PEG-1000 dropwise while stirring, continue stirring for 0.5h, then add 7.5g of diphenylmethane diisocyanate and 0.5g of dibutyltin maleate, and then place the three-necked flask with a condenser In a constant temperature water bath with a stirrer, the temperature of the constant temperature water bath is controlled to be 70° C., and the reaction is carried out under reflux for 2 hours to obtain a crude product. Centrifuge the crude product with a centrifuge, control the speed of the centrifuge to 5000r / m...

Embodiment 3

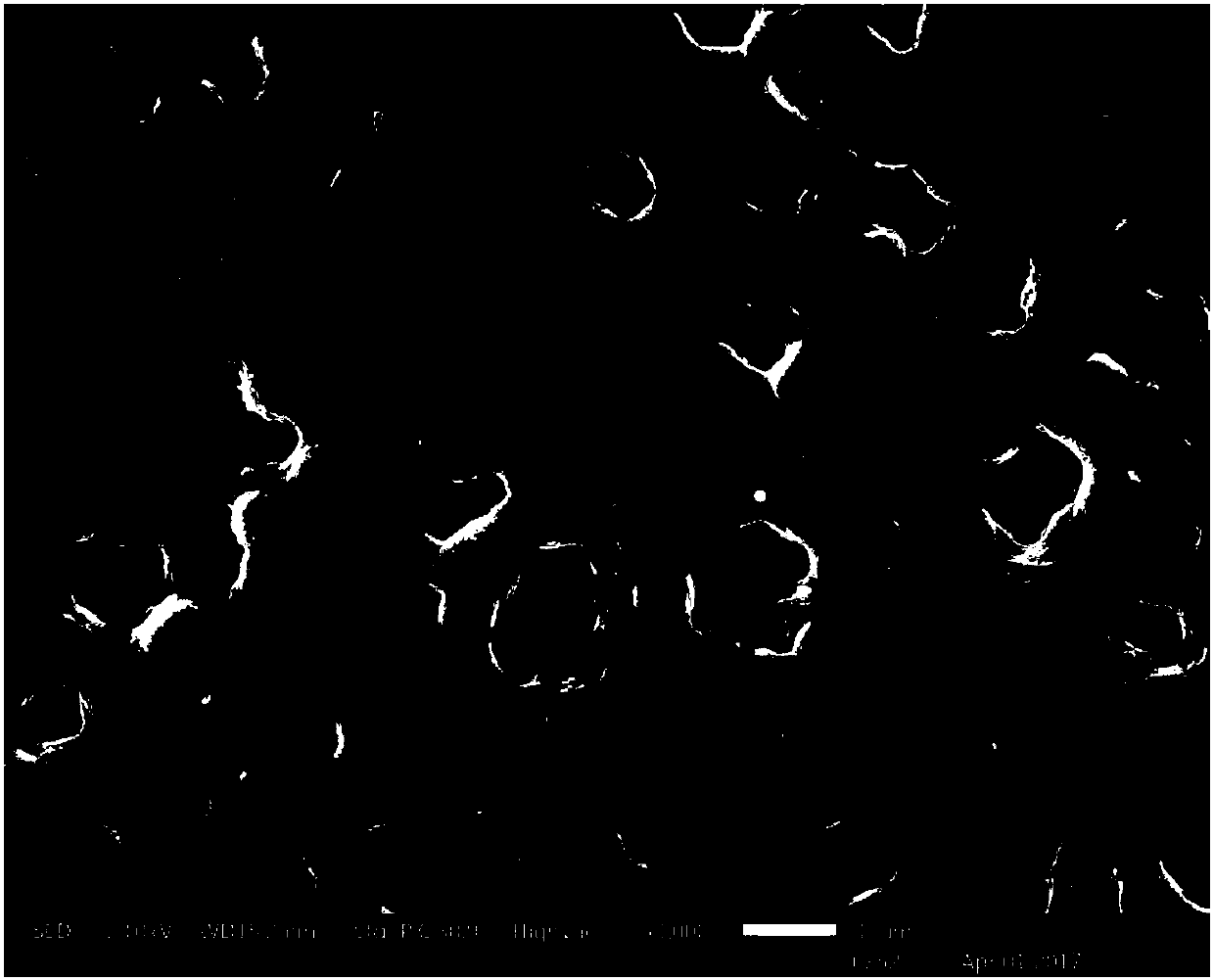

[0038]The raw material of porous carbon nanotubes is dried, then ultrasonically dispersed in acetic acid for acid treatment, and then dried for use; PEG-2000 is dried with silica gel for use before use. Take 80g of acid-treated porous carbon nanotubes and add them to a three-necked flask filled with 200ml of distilled water, stir and disperse evenly, heat the dried PEG-2000 to a molten state, and pour it into the three-necked flask at a stirring speed of 1000r / min Add 50g of molten PEG-2000 dropwise while stirring, continue stirring for 0.5h, then add 10g of diphenylmethane diisocyanate and 1g of dibutyltin maleate, then place a three-necked flask equipped with a condenser and stir In the constant temperature water bath of the device, the temperature of the constant temperature water bath was controlled to be 70° C., and the reaction was carried out under reflux for 2 hours to obtain the crude product. Centrifuge the crude product with a centrifuge, control the speed of the ce...

PUM

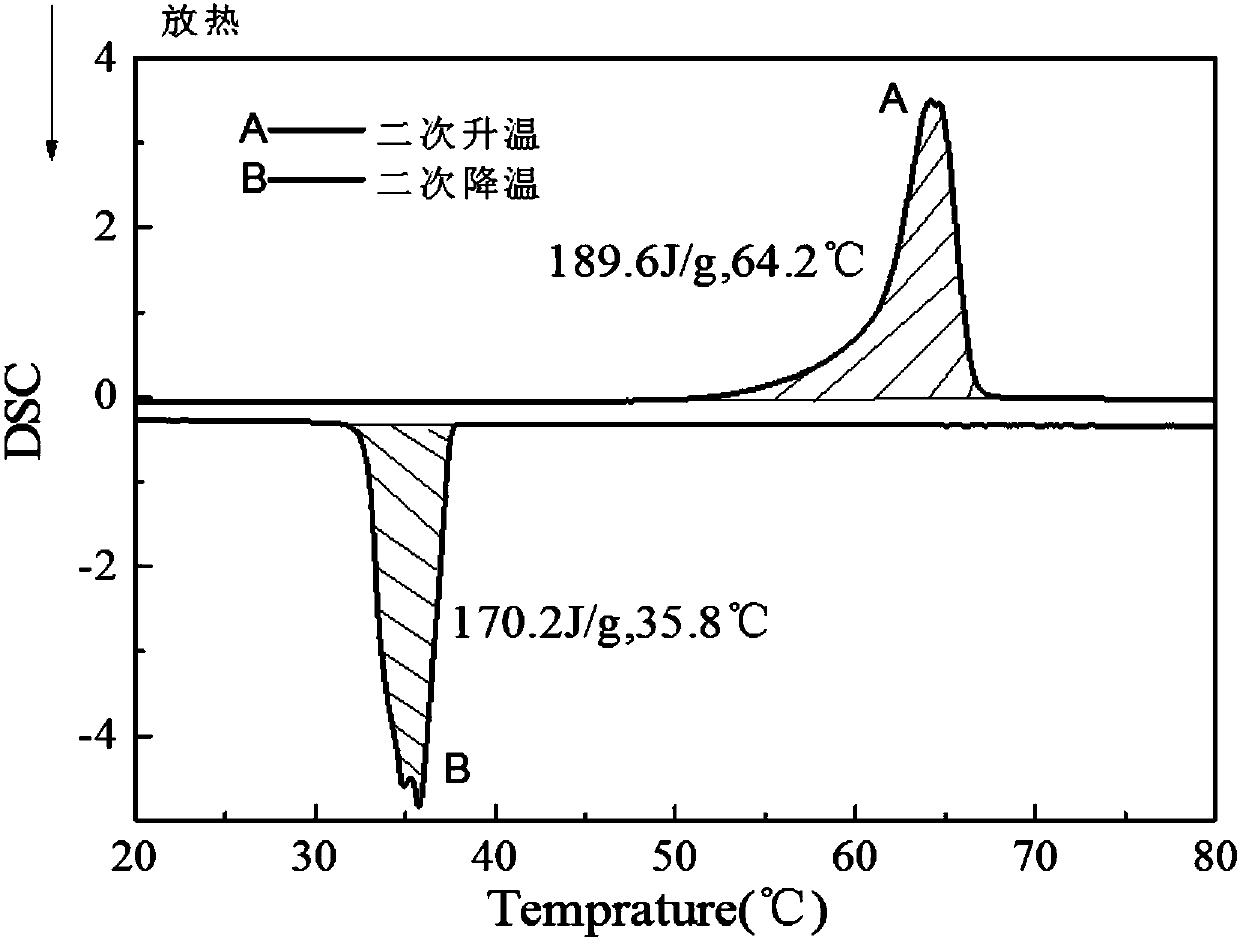

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com