Heat-insulating and anti-aging coating for interior of water storage barrel of solar water heater and processing technology thereof

A technology of solar water heaters and anti-aging coatings, applied in coatings and other directions, can solve the problems of frequent damage to water storage tanks, high maintenance costs, and excessive aging of the inner wall, and achieve good anti-aging performance, simple processing technology, and effective use significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A heat-insulating anti-aging coating for the interior of a solar water heater water storage tank, which is prepared from the following raw materials:

[0025] Butyl methacrylate 10kg, titanium dioxide 8kg, sodium hexametaphosphate 6kg, hydroxyethyl cellulose 6kg, talcum powder 5kg, alkyd resin 8kg, polyamide resin 50kg, sodium lauryl sulfate 8kg, shortening filler 20kg, Tributyl phosphate 6kg, styrene-acrylate copolymerized microemulsion 100kg;

[0026] The crisping filler is formed by mixing 6kg of diatomite, 5kg of montmorillonite powder, 6kg of starch and 2kg of quicklime, and then crisping, and the crisping method is as follows:

[0027] ①. After grinding diatomite, montmorillonite powder, starch and quicklime raw materials, mix them to obtain mixed fine materials;

[0028] 2. After mixing the above-mentioned dilute sulfuric acid of 3% of the total amount of mixed fine material raw materials, stir and compound evenly;

[0029] ③. Feed the raw materials in the abov...

Embodiment 2

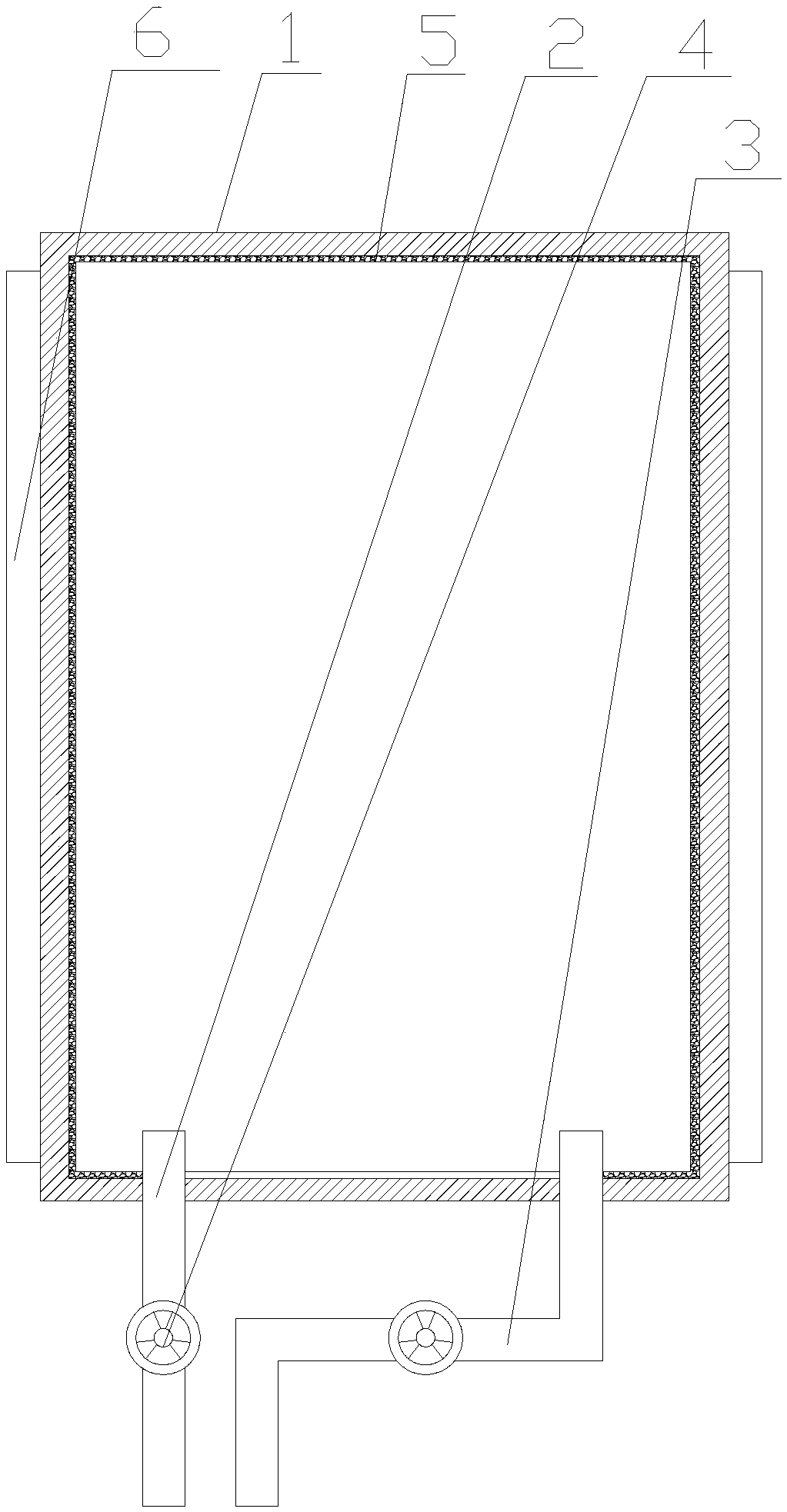

[0037] Such as figure 1 Said, as another embodiment of the present invention, a heat-insulating solar water storage tank, the main body is a cylinder 1, the bottom of the cylinder 1 is provided with a water inlet pipe 2 and a water outlet pipe 3, and the water inlet pipe 2 A valve 4 is installed on the water outlet pipe 3, a rough inner lining plate 5 is arranged on the inner wall of the cylinder body 1, and a heat-insulating anti-aging paint is painted on the inner lining plate 5, and the cylinder body 1 The outer wall is wrapped with a layer of asbestos cover 6; the function of asbestos cover 6 is used to realize the normal heat preservation effect in the cylinder, and at the same time, a rough inner lining plate 5 is arranged inside to realize the fastening performance after the paint is painted;

[0038] The heat-insulating anti-aging coating is prepared from the following raw materials:

[0039] Butyl methacrylate 11kg, titanium dioxide 9kg, sodium hexametaphosphate 7kg,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap