Fluorescent microcapsule and preparation method thereof

A microcapsule and fluorescence technology, applied in the directions of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., can solve the problem that there is no research report on graphene quantum dots, and achieve good biocompatibility, fluorescence and luminescence stability. Good, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation of fluorescent microcapsules

[0028] In this embodiment, the spherical core particle is a negatively charged spherical calcium carbonate core with a particle size of 4 μm, the cationic polyelectrolyte is polydiallyldimethylammonium chloride (PDDA), and negatively charged graphene quantum dots (GQDs ) is synthesized by a bottom-up method in the prior art, using 1,3,6-trinitropyrene as a carbon source and sodium hydroxide as a reaction medium (see Nature Communication, 2014, 5, 5357).

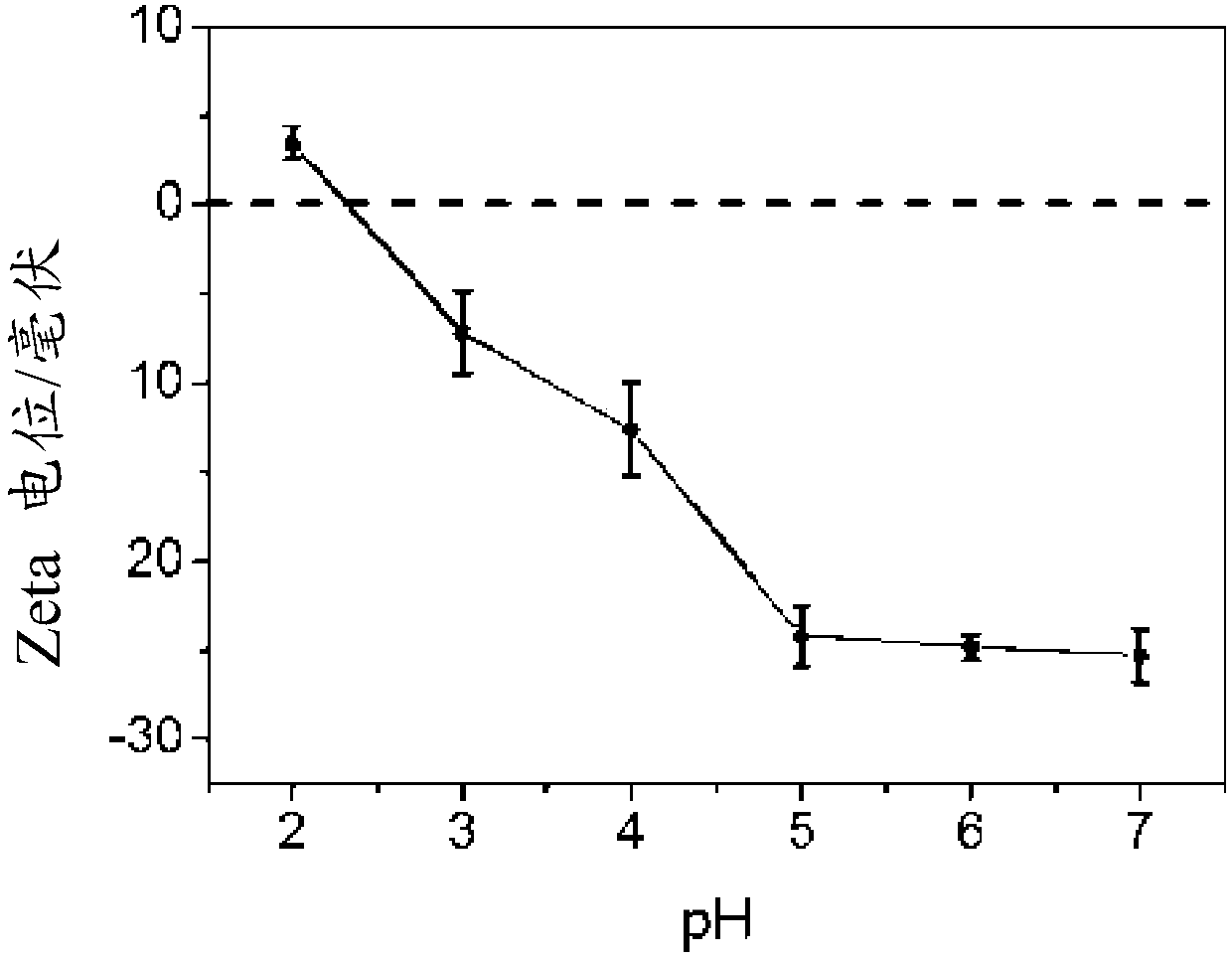

[0029] The layer-by-layer electrostatic self-assembly process of PDDA and negatively charged GQDs on the core material is as follows: at 25 °C, 10 mg of spherical calcium carbonate cores with a particle size of 4 μm were uniformly dispersed in 10 mL of positively charged GQDs with a concentration of 1.0 mg / ml. Assemble in PDDA solution, the assembly time is 30min, centrifuge to remove the supernatant, wash / centrifuge the particles twice with water, the first layer of assemb...

Embodiment 2

[0036] 1. Preparation of fluorescent microcapsules

[0037] In this embodiment, the spherical core particles are negatively charged polystyrene balls with a particle size of 2 μm, the cationic polyelectrolyte is dendritic polyethyleneimine (PEI), and the negatively charged graphene quantum dots (GQDs) are obtained by prior art Synthesized in a top-down method, using carbon black as a carbon source, and cleaved with hot nitric acid (see Journal of Materials Chemistry, 2012, 22, 8764).

[0038] The layer-by-layer electrostatic self-assembly process of PEI and negatively charged GQDs on the core material was as follows: 15 mg of polystyrene spheres with a particle size of 2 μm were uniformly dispersed in 10 mL of positively charged GQDs at a concentration of 0.8 mg / ml at 25 °C. The assembly time is 20min in PEI solution, the supernatant is removed by centrifugation, the microparticles are washed / centrifuged three times with water, and the first layer of assembly is completed; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com