A method and product for preparing autofluorescent polystyrene material

A technology of polystyrene and autofluorescence, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems that fluorescent dye molecules are easily disturbed by the environment, it is difficult to obtain high molecular weight polymers, and dyes are easy to fall off, so as to achieve no fluorescence Leakage phenomenon, high mechanical strength, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

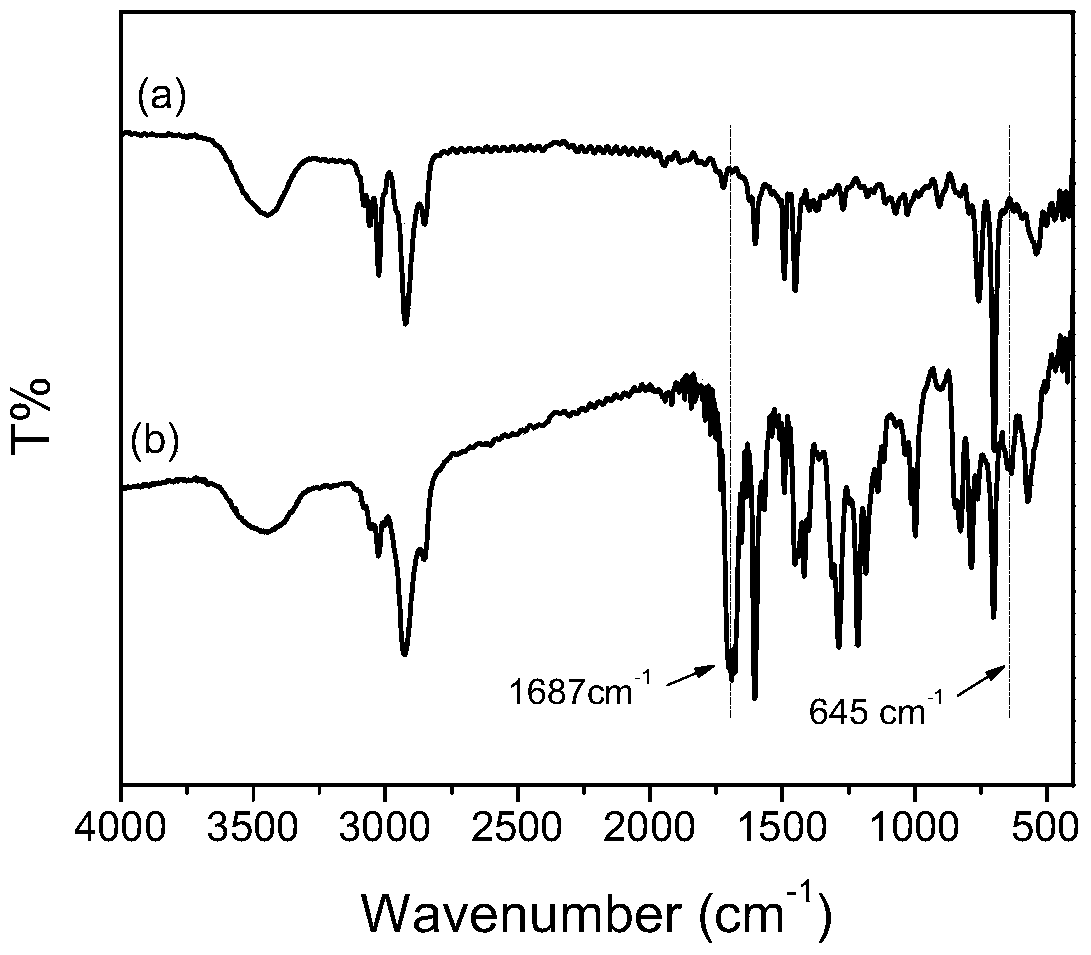

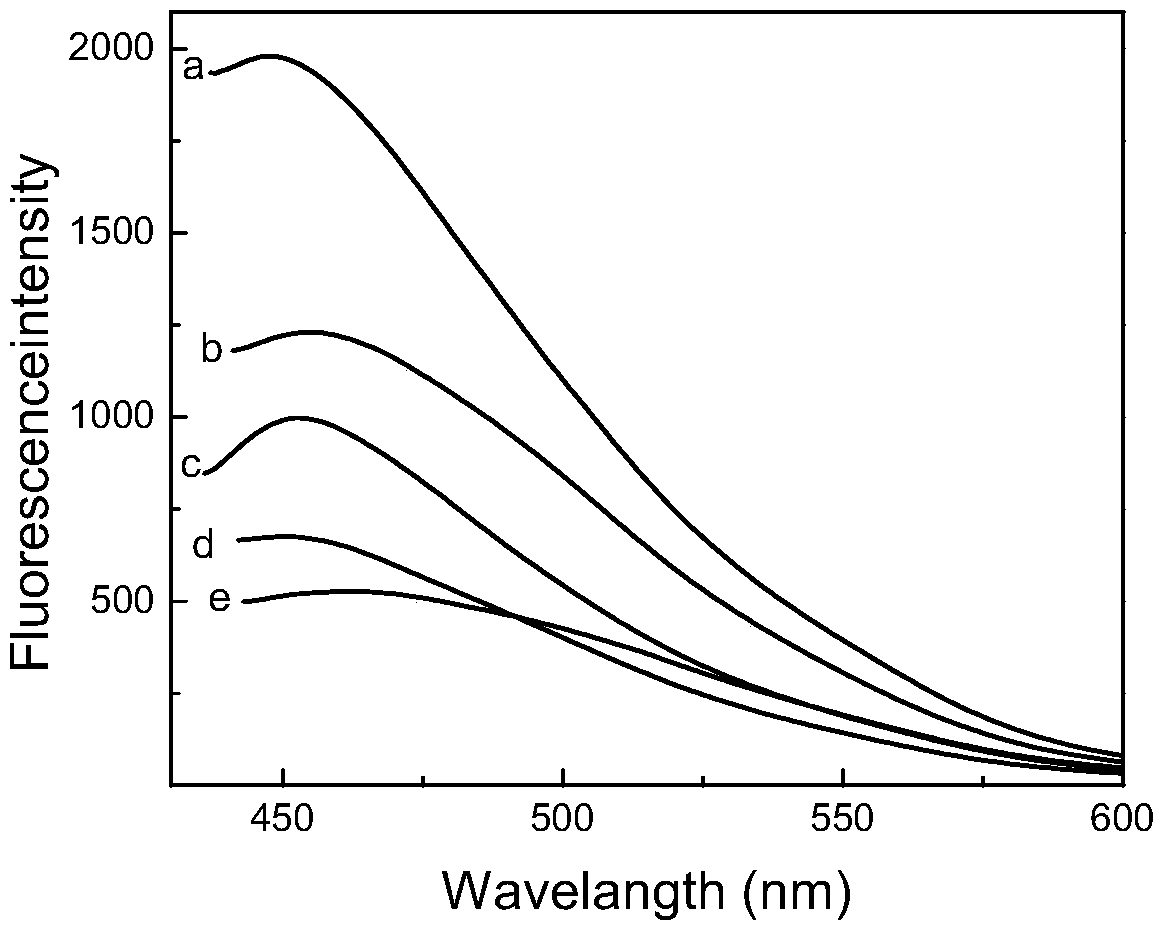

Embodiment 1

[0034] Weigh 2g of linear polystyrene (PS) into a three-necked flask and add 30ml of carbon disulfide to soak and dissolve, then add anhydrous AlCl 3 4.5g and 5.25g of chlorobutyryl chloride (CBC), stirred and reacted for 5h under the condition of reflux condensation, and the reaction temperature was 40°C. After the reaction was completed, it was cooled to room temperature and precipitated with ethanol, and then separated by microporous membrane filtration to obtain The solid matter was quickly poured into glacial hydrochloric acid and stirred, filtered again and washed with deionized water until neutral, finally washed and filtered with absolute ethanol, and dried in a vacuum oven to obtain the autofluorescent polystyrene material PS-CBC. Finally, the prepared polystyrene fluorescent material was heated and dissolved in a tetrahydrofuran solution, and a film was spin-coated on a glass plate, and an autofluorescent polystyrene film was obtained after the solvent evaporated.

Embodiment 2

[0036] Weigh 2 g of cross-linked polystyrene microspheres (PS) into a three-necked flask, add 30 ml of dichloroethane to soak and swell, and then add anhydrous AlCl 34.5g and 4.12g of chloroacetyl chloride (CAC), stirred and reacted for 4h under the condition of reflux condensation, and the reaction temperature was 50°C. After the reaction was completed, the sample was separated by filtration with a microporous membrane, and the filtered solid matter was quickly poured into glacial hydrochloric acid Stir, filter again and wash with deionized water until neutral, finally wash and filter with absolute ethanol, and dry in a vacuum oven to prepare autofluorescent polystyrene microspheres PS-CAC.

Embodiment 3

[0038] Weigh 2 g of cross-linked polystyrene microspheres (PS) and place them in a three-necked flask, add 30 ml of dichloromethane to soak and dissolve, then add anhydrous ZnCl 2 5.0g and 6.32g of 2-bromoisobutyryl bromide (BIBB), stirred and reacted for 5h under the condition of reflux condensation, and the reaction temperature was 60°C. Pour into glacial hydrochloric acid and stir, filter again and wash with deionized water until neutral, and finally wash and filter with absolute ethanol, and dry in a vacuum oven to prepare autofluorescent polystyrene microspheres PS-BIBB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com