Method for preparing large-area double-layer graphene film on insulated liner

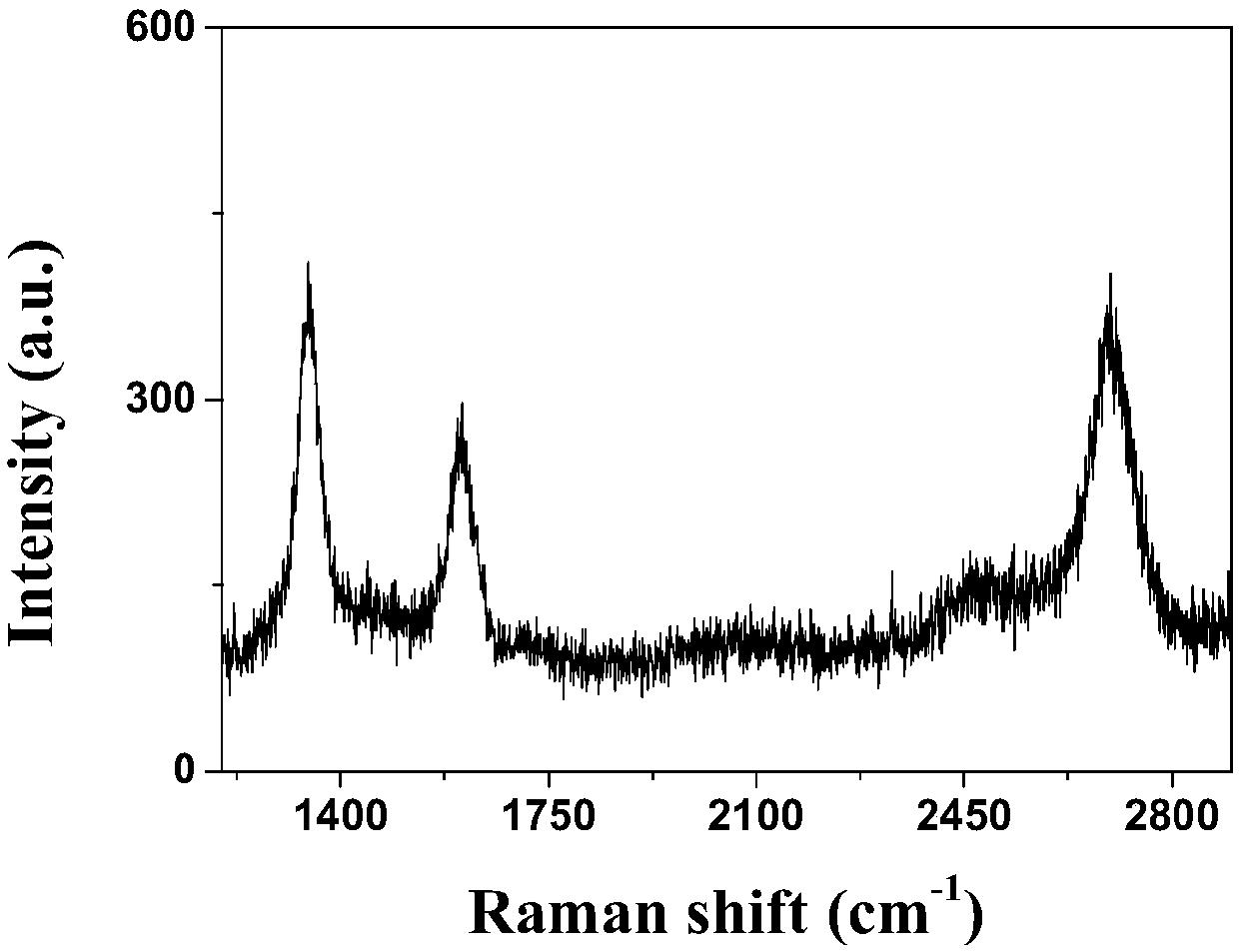

A double-layer graphene, insulating substrate technology, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the problem of carrier mobility decay, loss of graphene electrical properties, and damage to graphene Lattice structure and other problems, to achieve the effect of less defects, convenient operation and high mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

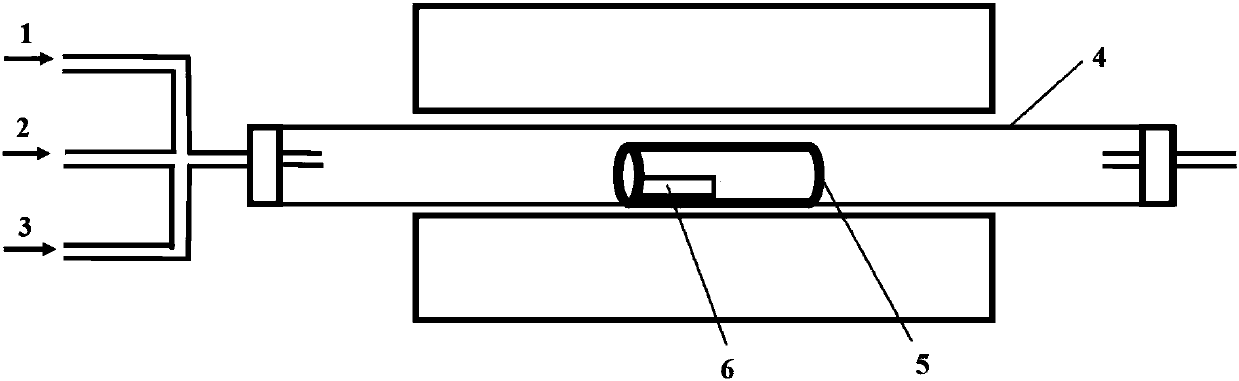

[0024] Such as figure 1 As shown, the carbon source is methane, the copper tube is polycrystalline copper foil, the reactor 4 is a quartz tube, the No. 1 tube is an argon gas tube, the No. 2 tube is a hydrogen gas tube, and the No. 3 tube is a methane gas tube.

[0025] A method for preparing a large-area double-layer graphene film on an insulating substrate, comprising the following steps:

[0026] a) Prepare the composite substrate: the composite substrate includes an external copper tube 5, and an insulating substrate 6 arranged inside the copper tube 5, the insulating substrate 6 is located within the range of the copper tube 5, and the copper tube 5 acts as The role of the catalyst: a small quartz tube with a diameter of 1.5 to 5mm is used as a mold, and the polycrystalline copper foil is curled and extended along the inner wall of the quartz tube to form a copper tube. In the first embodiment, a 1.8mm quartz tube is used as a mold;

[0027] b) Place the copper tube in a...

Embodiment 2

[0033] Such as figure 1 As shown, the carbon source is acetylene, and it can also be a mixed gas of methane and acetylene. The copper tube 5 is a single crystal copper foil, the reactor is a quartz tube, the No. 1 tube is an argon tube, the No. 2 tube is a hydrogen tube, and the No. 3 tube A gas pipe for a mixture of methane and acetylene.

[0034] A method for preparing a large-area double-layer graphene film on an insulating substrate, comprising the following steps:

[0035] a) Prepare the composite substrate: the composite substrate includes an external copper tube 5, and an insulating substrate 6 arranged inside the copper tube 5, the insulating substrate 6 is located within the range of the copper tube 5, and the copper tube 5 acts as The role of the catalyst: using the inner wall of the reactor 4 as a mold, the single crystal copper foil is curled and extended along the inner wall of the reaction tube 4 to form a copper tube 5, and then two insulating substrates 6 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com