A method for quantitative detection of β-lactoglobulin in milk powder

A technology for quantitative detection of lactoglobulin, applied in the field of fluorescent sensing technology, biological analysis and detection, and nanomaterials, to achieve good water solubility, high sensitivity, and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 Preparation of carboxylated ferroferric oxide magnetic nanoparticles, the steps are as follows:

[0038] 0.54g of ferric chloride hexahydrate and 1.44g of sodium acetate were dissolved in 10mL of ethylene glycol. Subsequently, the sodium acetate solution was slowly added dropwise to the ferric chloride solution under stirring. After stirring for 30 minutes, it was placed in a high-pressure reactor, reacted at 200°C for 4h, cooled to room temperature, washed several times with ethanol and deionized water, and dried in vacuum at 40°C for 12h. For the Fe 3 o 4 To modify the carboxyl group on the surface, ultrasonically dissolve 10.5 g of citric acid monohydrate in 100 mL of ultrapure water, and add 0.5 g of Fe prepared above 3 o 4 , and stirred mechanically at room temperature for 4h. Finally, the resulting product was washed several times with deionized water and ethanol, and dried under vacuum at 40°C to obtain the carboxyl-modified Fe 3 o 4 magnetic nan...

Embodiment 2

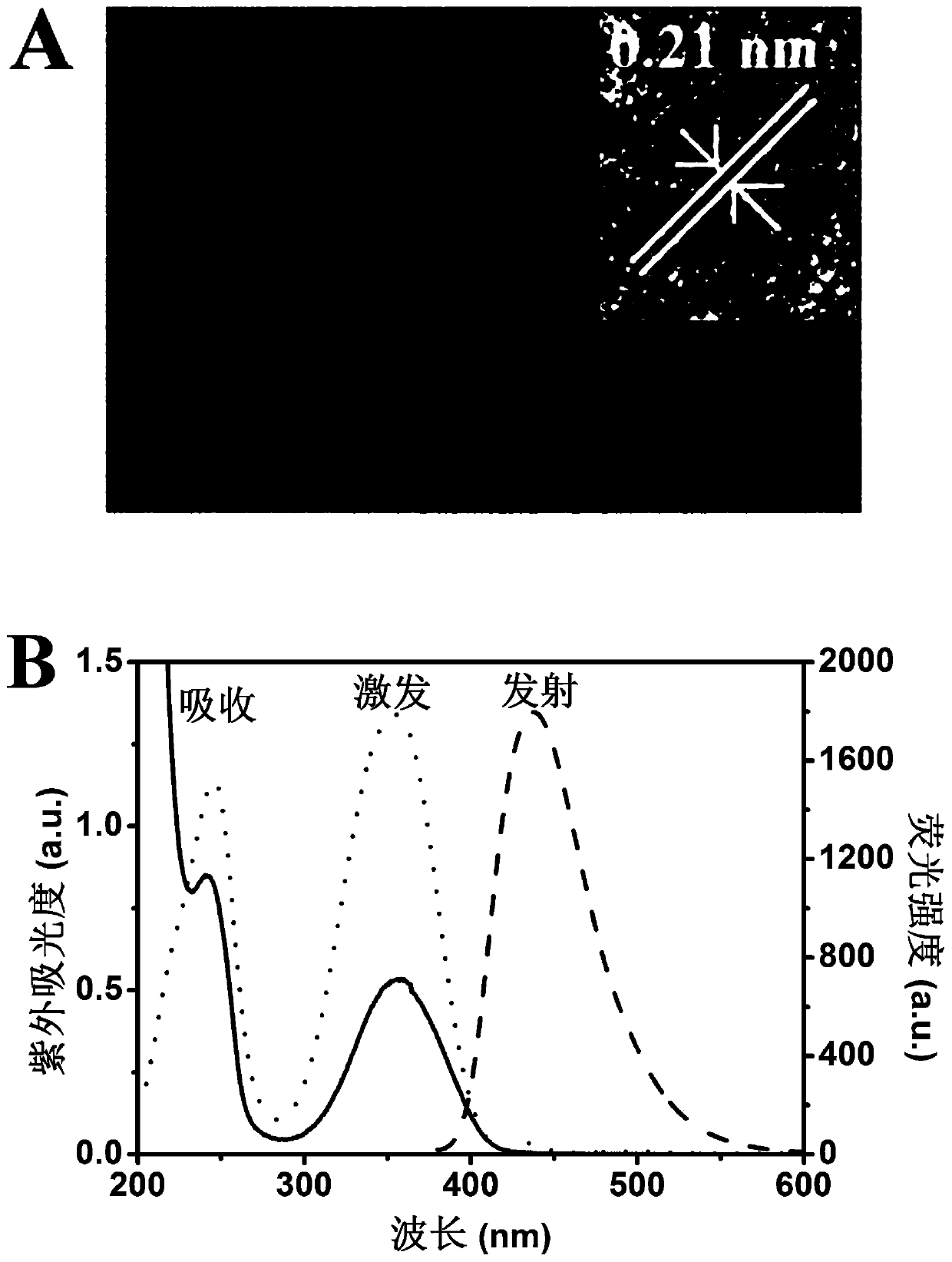

[0039] Example 2 The preparation of carbon dot CDs, the steps are as follows:

[0040] Take 1.2g of citric acid monohydrate, 0.6mL of diethylenetriamine and 20mL of ultrapure water in a 30mL autoclave, ultrasonically dissolve, and react at 200°C for 4h; take out the autoclave and place it at room temperature to obtain a brown solution, which is CDs solution; in order to purify CDs, the resulting CDs solution was concentrated, added acetone for purification and then dried in vacuum at 50°C; the obtained CDs were light yellow powder. Its transmission electron microscope picture, ultraviolet absorption and fluorescence excitation and emission picture are as follows figure 2 shown.

Embodiment 3

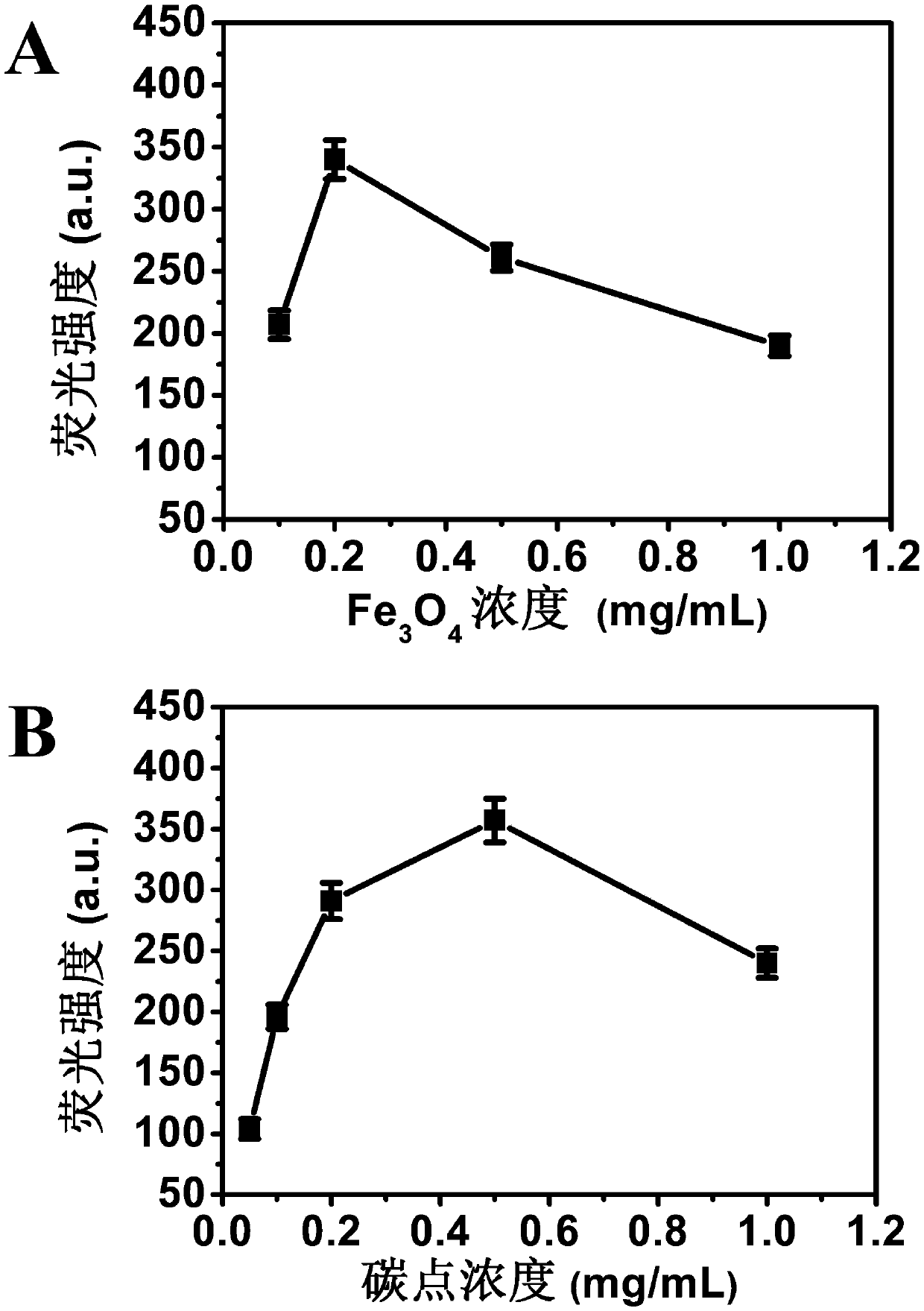

[0041] Embodiment 3 prepares Fe 3 o 4 -Aptamer complex, the steps are as follows:

[0042] Carboxy-modified Fe 3 o 4 Magnetic nanoparticles were dissolved in acidic PBS and prepared into 0.1, 0.2, 0.5, 1.0 mg / mL solutions, EDC and NHS were added to the above solution, and activated at room temperature for 30 min; the pH was adjusted to weak alkalinity with 1M NaOH, and appropriate Ligand, incubate overnight at room temperature. Finally, magnetic separation, washed with PBS to remove excess aptamers and impurities, redissolved in PBS for later use, and investigated carboxy-modified Fe 3 o 4 The effect of the concentration of magnetic nanoparticles on the response of the target, the results are as follows image 3 As shown in A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com