Method for preparing self-supporting GaN substrate material

A substrate material, self-supporting technology, applied in the direction of polycrystalline material growth, chemical instruments and methods, from chemically reactive gases, etc., can solve the problems of GaN-based materials and device performance degradation, and achieve the effect of reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

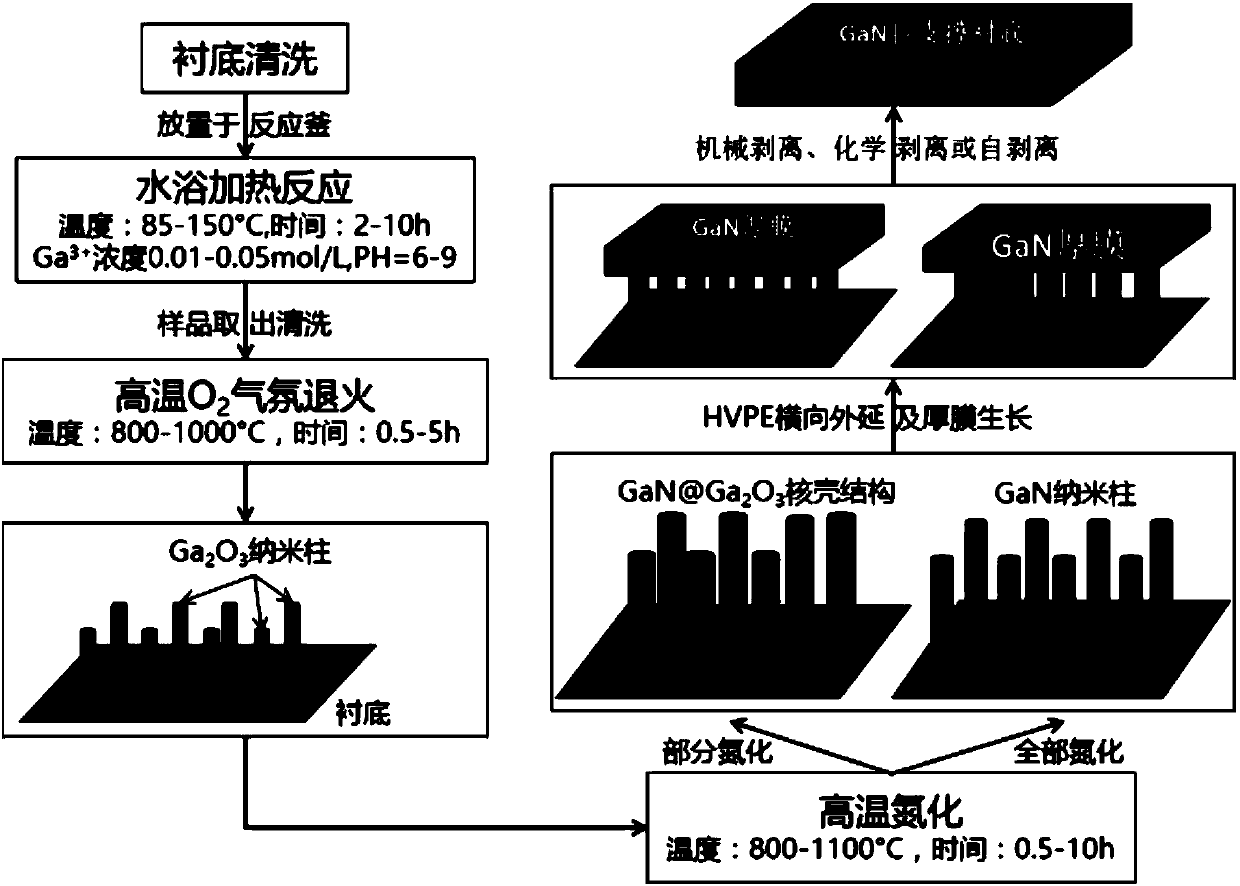

[0020] The method and process of the present invention include several parts: preparation of gallium oxide nanocolumn ordered array by hydrothermal method; gallium oxide nanocolumn array nitriding to form gallium nitride nanocolumn array; HVPE of GaN thick film on gallium nitride nanocolumn array regrowth. See the schematic diagram of the specific technical route figure 1 .

[0021] One of the technical implementations of the present invention, the preparation of the self-supporting gallium nitride substrate material includes the following steps:

[0022] 1. Cleaning and processing of the substrate (sapphire or silicon wafer).

[0023] 2. Prepare a solution with a certain concentration of Group III elements and a pH value. Such as: in this embodiment, the Ga(NO 3 ) 3 Dissolving nH2O in deionized water makes Ga 3+ The concentration is 0.01-0.05mol / L as the source of gallium, and the pH of the solution is adjusted to 6.7 by continuously adding hexamethylenetetramine powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com