Polymerization method for preparing fluorine-containing alternative polymer through photocatalyst

A technology of photocatalyst and polymerization method, which is applied in the field of polymerization of fluorine-containing alternating polymers prepared by photocatalyst, which can solve the problems of brush-like polymer reports and achieve the effect of green reaction and pollution avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

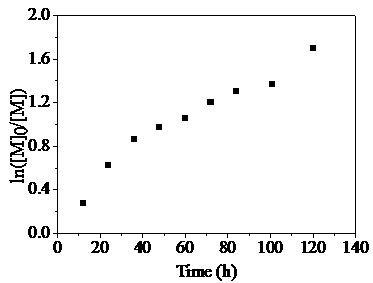

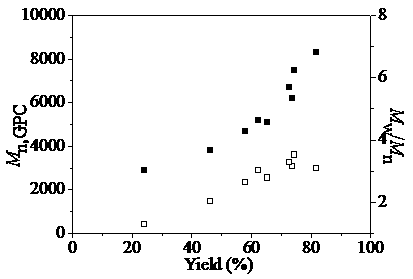

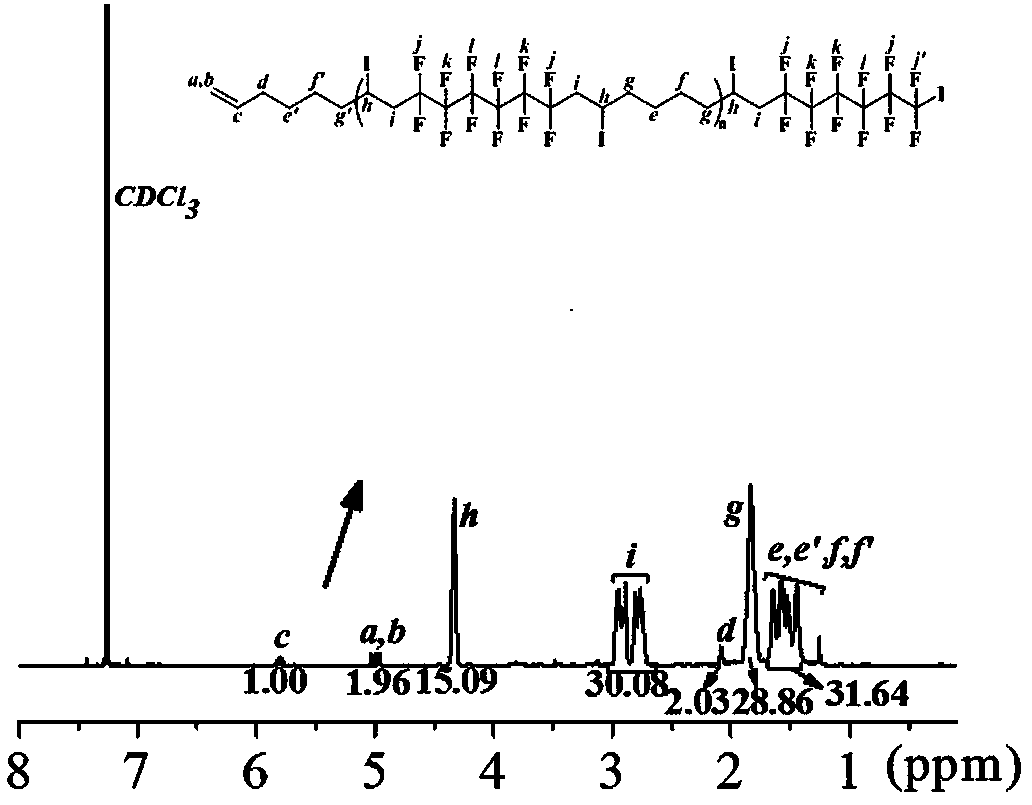

[0031] Metal-free stepwise transfer-addition-terminated polymerization catalyzed by 2,4,6-triphenylmethoxypyranyl tetrafluoroborate (1b) in a mixed solvent system of dimethyl carbonate and acetonitrile

[0032] according to n A2 :n B1 :n 1b :n AsAc-Na = 100:100:10:50 initial molar ratio, bifunctional monomer A2 (1,6-diiodoperfluorohexane) (0.2769 g, 0.5 mmol), B1 (1,7-octadiene) (74.0 μL, 0.5 mmol), 2,4,6-tri-p-phenylmethoxypyranyl tetrafluoroborate (1b) (12.5 mg, 0.05 mmol), AsAc-Na (49.6 mg, 0.25 mmol) were added to In the mixed solvent system of acetonitrile and dimethyl carbonate (V 乙腈 :V 碳酸二甲酯 =1:3), add a stirring bar, and seal the tube directly after four deoxygenation operations. Then transfer the ampoule to a magnetic stirrer with a set speed (1800 rpm) and carry out photopolymerization at room temperature under LED blue light illumination. After reaching the given time (24 h), take out and open the airtight container, and use the polymerization system to Tet...

Embodiment 2

[0034] Effect of different organic photocatalysts on metal-free catalyzed free radical transfer-addition-termination polymerization in mixed solvent system of dimethyl carbonate and acetonitrile

[0035] Through the deletion and selection of various types of organic photocatalysts and a large number of literature research, we mainly use p-methoxybenzaldehyde (1a), 2,4,6-tri-p-benzyloxypyran Tetrafluoroborate (TPP+BF4-) (1b) and eosin Y (1c) were used as organic photocatalysts to catalyze the alternating copolymerization of perfluorodiiodide monomers and non-conjugated diene monomers. Since p-methoxybenzaldehyde (1a) acts as a photosensitizer, it mainly catalyzes the polymerization reaction through the energy transfer process, while 2,4,6-tri-p-benzyloxypyranyl tetrafluoroborate (1b) and Eosin Y (1c) has excellent photoredox properties and catalyzes the polymerization reaction mainly through a reversible electron transfer process. The specific catalytic effect results of these...

Embodiment 3

[0041] Using 2,4,6-tri-p-phenylmethoxypyranyl tetrafluoroborate (1b) as an organic photocatalyst, the effect of different solvent system ratios on metal-free catalyzed stepwise transfer-addition-termination polymerization

[0042] In view of the activity of perfluoro radicals and the reaction efficiency between functional groups, in the metal-free catalyzed radical transfer-addition-termination polymerization system of perfluoro diiodide monomers and non-conjugated diene monomers, the solvent The polarity of the polymer can affect the initiation efficiency of the entire polymerization process, the reaction rate and the degree of side reactions. In addition, since fluoropolymers are poorly soluble in conventional solvents, finding a solvent system with good solubility for the polymer is a key factor to improve the polymerization efficiency. According to the method recorded in Example 1, we plan to adopt different mixed solvent systems, such as tetrahydrofuran, dimethyl carbonat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com