Composite wood plastic building template

A technology for building formwork and composite wood, which is used in buildings, building structures, formwork/formwork components, etc., can solve problems such as poor mechanical properties, and achieve improved interface contact state, improved mechanical properties, and increased crosslinking density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

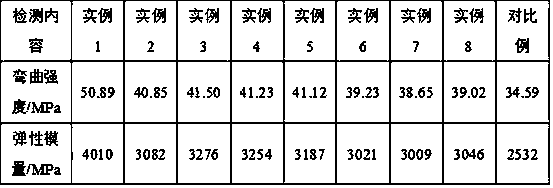

Examples

example 1

[0025] In parts by weight, put 30 parts of wood flour fiber, 6 parts of pectinase and 100 parts of water in the No. 1 beaker, and place the No. 1 beaker in a digital speed measuring constant temperature magnetic stirrer at a temperature of 32°C , At a speed of 400r / min, heating and stirring for 60 minutes to obtain a mixed solution, and then filter the mixed solution to obtain a filter residue, and then place the filter residue in an oven and dry to a moisture content of 3% to obtain dry wood flour fiber; Dry wood flour fiber and isocyanate are placed in the No. 2 beaker according to the mass ratio of 1:30, and the No. 2 beaker is placed in the digital display speed constant temperature magnetic stirrer, and the speed is 400r / min. Stir and immerse for 40 minutes. And then filter the impregnating solution to obtain modified wood flour fiber; add wood flour particles and 30% potassium permanganate solution with a mass ratio of 1:100 into the No. 3 beaker, and place the No. 3 beake...

example 2

[0027] In parts by weight, put 30 parts of wood flour fiber, 6 parts of pectinase and 100 parts of water in the No. 1 beaker, and place the No. 1 beaker in a digital speed measuring constant temperature magnetic stirrer at a temperature of 32°C , At a speed of 400r / min, heating and stirring for 60 minutes to obtain a mixed solution, and then filter the mixed solution to obtain a filter residue, and then place the filter residue in an oven and dry to a moisture content of 3% to obtain dry wood flour fiber; Dry wood flour fiber and isocyanate are placed in the No. 2 beaker according to the mass ratio of 1:30, and the No. 2 beaker is placed in the digital display speed constant temperature magnetic stirrer, and the speed is 400r / min. Stir and immerse for 40 minutes. And then filter the impregnating solution to obtain modified wood flour fiber; add wood flour particles and 30% potassium permanganate solution with a mass ratio of 1:100 into the No. 3 beaker, and place the No. 3 beake...

example 3

[0029] In parts by weight, put 30 parts of wood flour fiber, 6 parts of pectinase and 100 parts of water in the No. 1 beaker, and place the No. 1 beaker in a digital speed measuring constant temperature magnetic stirrer at a temperature of 32°C , At a speed of 400r / min, heating and stirring for 60 minutes to obtain a mixed solution, and then filter the mixed solution to obtain a filter residue, and then place the filter residue in an oven and dry to a moisture content of 3% to obtain dry wood flour fiber; Dry wood flour fiber and isocyanate are placed in the No. 2 beaker according to the mass ratio of 1:30, and the No. 2 beaker is placed in the digital display speed constant temperature magnetic stirrer, and the speed is 400r / min. Stir and immerse for 40 minutes. Then filter the impregnating solution to obtain modified wood flour fiber; add flake wood flour and 30% potassium permanganate solution in mass ratio 1:100 into No. 4 beaker, and add No. 4 beaker Placed in a digital sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com