Wound dressing with multi-layer structure and preparing method and application thereof

A technology of wound dressing and multi-layer structure, applied in the field of wound dressing, which can solve the problems of low lateral diffusion, inability to keep the surface of the dressing dry, and not solve the problems of exudate impregnation of the wound and healthy skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

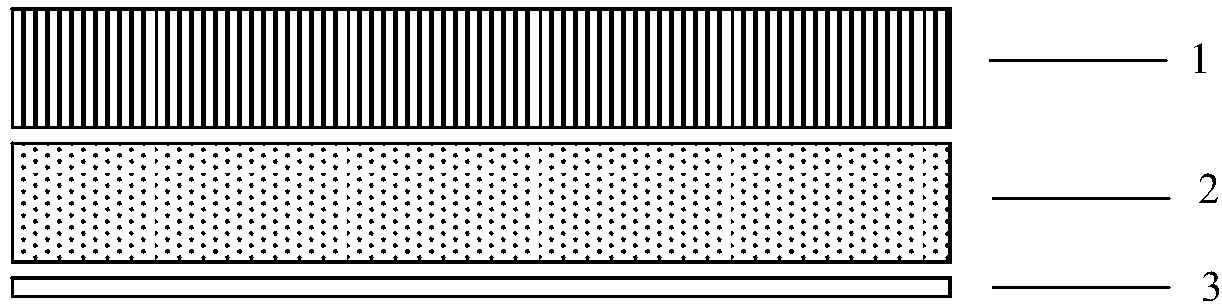

[0072] Example 1: A wound dressing with a three-layer structure.

[0073] figure 1 It is a structure diagram of a wound dressing with a three-layer structure. see figure 1 , the wound dressing with a three-layer structure in this embodiment has a liquid conduction layer 1, a liquid storage layer 2 and an outer protective layer 3, wherein the liquid conduction layer: contains 75% by weight of polypropylene fiber, 25% by weight of viscose fiber. Among them, the fineness of polypropylene fiber is 2.0dtex and the length is 38mm; the fineness of viscose fiber is 1.67dtex and the length is 38mm. The two fibers are weighed in proportion and mixed, and then opened, carded, laid, and needled to form a liquid-conducting layer of needle-punched nonwoven fabric, with a grammage of 310 grams per square meter.

[0074] Reservoir: Contains 50% superabsorbent cross-linked acrylic fibers by weight, 50% lyocell fibers by weight. The superabsorbent cross-linked acrylic fiber has a fineness ...

Embodiment 2

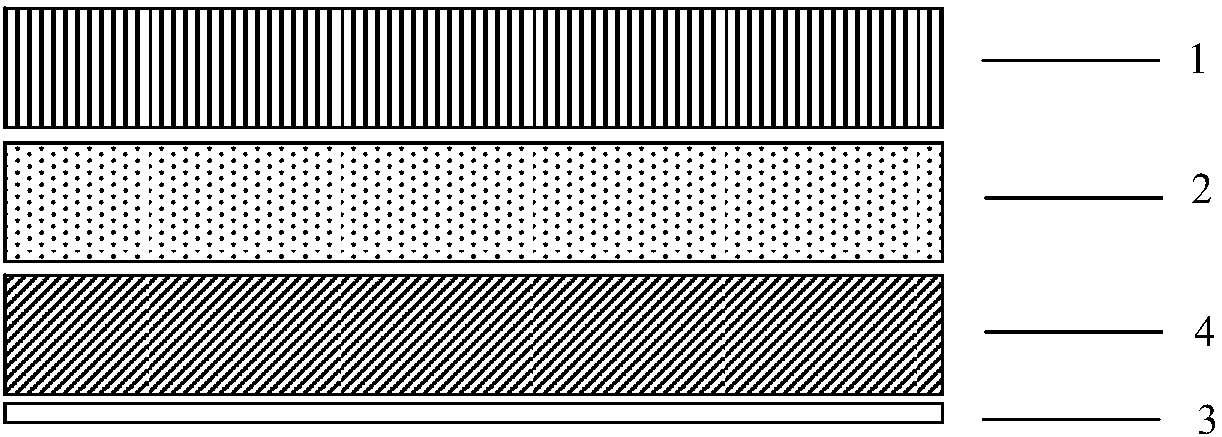

[0084] Example 2: A wound dressing with a four-layer structure.

[0085] image 3 It is a structure diagram of a wound dressing with a four-layer structure. see image 3 , in this embodiment, the wound dressing with four-layer structure includes a liquid conduction layer 1, a liquid storage layer 2, a buffer layer 4 and an outer protective layer 3, wherein the liquid conduction layer: contains 70% by weight of polypropylene fibers, 30 % by weight lyocell fibers. The fineness of polypropylene fiber is 2.0dtex and the length is 38mm; the fineness of lyocell fiber is 1.7dtex and the length is 51mm. The two fibers were weighed in proportion and mixed, and then opened, carded, laid, and needled to make a liquid-conducting layer of needle-punched non-woven fabric, with a grammage of 270 grams per square meter.

[0086] Reservoir: Contains 50% superabsorbent cross-linked acrylic fibers by weight, 50% polypropylene fibers by weight. The superabsorbent cross-linked acrylic fiber h...

Embodiment 3

[0093] Example 3: A wound dressing having a four-layer structure, wherein the reservoir layer contains an antimicrobial agent.

[0094] In this embodiment, the wound dressing has a four-layer structure including a liquid transfer layer, a liquid storage layer, a buffer layer and an outer protective layer. Wherein, the liquid conduction layer: contains 75% by weight of polypropylene fiber and 25% by weight of calcium alginate fiber. The fineness of the polypropylene fiber is 2.0dtex and the length is 38 mm; the fineness of the calcium alginate fiber is 2.5 dtex and the length is 51 mm. The two kinds of fibers are weighed in proportion and mixed, and after opening, carding, laying and needle punching, the liquid conducting layer of needle punched non-woven fabric is made, and its grammage is 250 g / m2.

[0095] Liquid storage layer: Contains 60% by weight of superabsorbent cross-linked acrylic fibers, 40% by weight of silver-containing calcium alginate fibers, and the silver con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com