Titanium dioxide nanowire and preparation method thereof

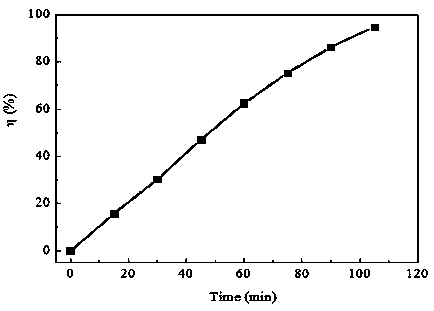

A titanium dioxide and nanowire technology, applied in the directions of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of difficult nanowire shape control, cumbersome preparation steps, high production cost, and achieve good photocatalysis. , The effect of shortening the process flow and reducing the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] TiO was prepared by the following procedure 2 Nanowires:

[0043] (1) Fully mix 8mL butyl titanate and 16mL absolute ethanol, slowly drop 3mL of 10mol / L NaOH solution under magnetic stirring, and obtain a uniform precursor solution after magnetic stirring for 30min;

[0044] (2) Put the precursor solution in a 50mL hydrothermal reaction kettle, and conduct a hydrothermal reaction at 180°C in a constant temperature drying oven for 24 hours;

[0045] (3) Separate the solid substance obtained after the hydrothermal reaction, pickle with 0.1mol / L HCl for 12 hours, wash the precipitate after pickling with deionized water until neutral, and then dry the precipitate after washing with water at 80°C drying in the oven to obtain metatitanic acid;

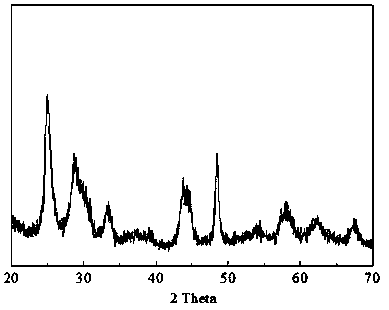

[0046] (4) Grind the dried metatitanate into powder, put it into a muffle furnace, heat it for 1 hour, then raise the temperature to 450°C, keep it for 2 hours, and then cool it with the furnace;

[0047] (5) Grinding the sintered ...

Embodiment 2

[0053] TiO was prepared by the following process 2 Nanowires:

[0054] (1) Mix the titanium source with an organic reagent, and conduct a hydrothermal reaction under the action of an alkali to obtain a nano-titanium salt;

[0055] (2) reacting the nano-titanium salt with an acid to obtain an intermediate product;

[0056](3) roasting the intermediate product to obtain the titanium dioxide nanowire;

[0057] in:

[0058] Titanium source is butyl titanate;

[0059] The organic reagent is ethanol;

[0060] The volume ratio of titanium source to organic reagent is 1:1.5~3;

[0061] The concentration of alkali is 5~15mol / L, preferably strong alkali, further, the volume ratio of titanium source and alkali is 1:0.3~0.4;

[0062] The temperature of the hydrothermal reaction is 170~190°C, and the reaction time is preferably 18~26h;

[0063] H of the acid described in step (2) + The concentration is 0.05~0.15mol / L;

[0064] The roasting temperature in the step (3) is 400-500° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com