Preparation method for all-solid-state environment-friendly biopolymer electrolyte film

A technology of biopolymers and electrolyte membranes, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as environmental pollution and environmental hazards, and achieve the effects of reducing pollution, simple acquisition, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

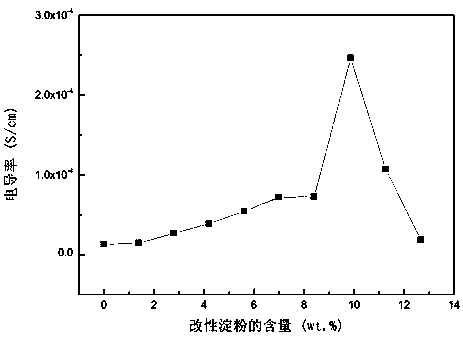

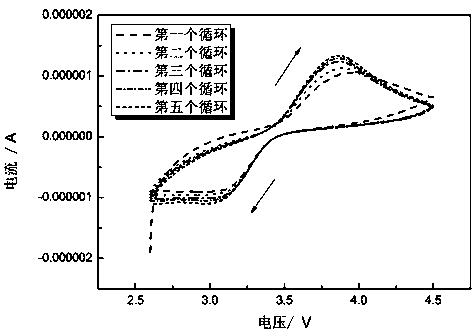

[0015] Embodiment 1: The preparation method of a kind of all-solid environment-friendly biopolymer electrolyte membrane of this embodiment is carried out according to the following steps:

[0016] 1. Preparation of modified starch

[0017] Carry out modification to potato starch, stand-by;

[0018] 2. Preparation of all-solid-state environment-friendly biopolymer electrolyte membrane

[0019] Weigh a certain amount of modified starch and cellulose acetate with a weighing bottle, add solvent, blend and stir on a magnetic stirrer at room temperature for 12 hours, then add lithium salt and stir for 6 hours, pour the solution onto a glass plate, put In a vacuum drying oven, dry at 0.08MPa and 120°C for 40min to obtain the product electrolyte membrane.

specific Embodiment approach 2

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the preparation method of an all-solid-state environment-friendly biopolymer electrolyte membrane described in step 1 is characterized in that the preparation method of modified starch is: taking starch Heating with solvent N,N-dimethylformamide in a water bath at 60°C for 30 minutes, then adding phthalic anhydride and pyridine and continuing to blend and stir in a water bath until the solution becomes a uniform paste, then Precipitate the modified starch with isopropanol, then put it into a vacuum drying oven, dry it at 0.08 MPa and 120°C, and grind the product after drying to obtain the modified starch. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and one of the specific embodiments one to two is that the preparation method of an all-solid-state environment-friendly biopolymer electrolyte membrane described in step two is characterized in that the lithium salt used is Lithium bistrifluoromethanesulfonyl imide. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com