Caked soil smashing and recycling device

A soil crushing and processing device technology, which is applied in fertilization devices, grain processing, soil conditioning materials, etc., can solve the problems of blocked water and inorganic salt absorption, difficult crop absorption of nutrients, unfavorable crop planting, etc., to promote aggregation and low cost , has the effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

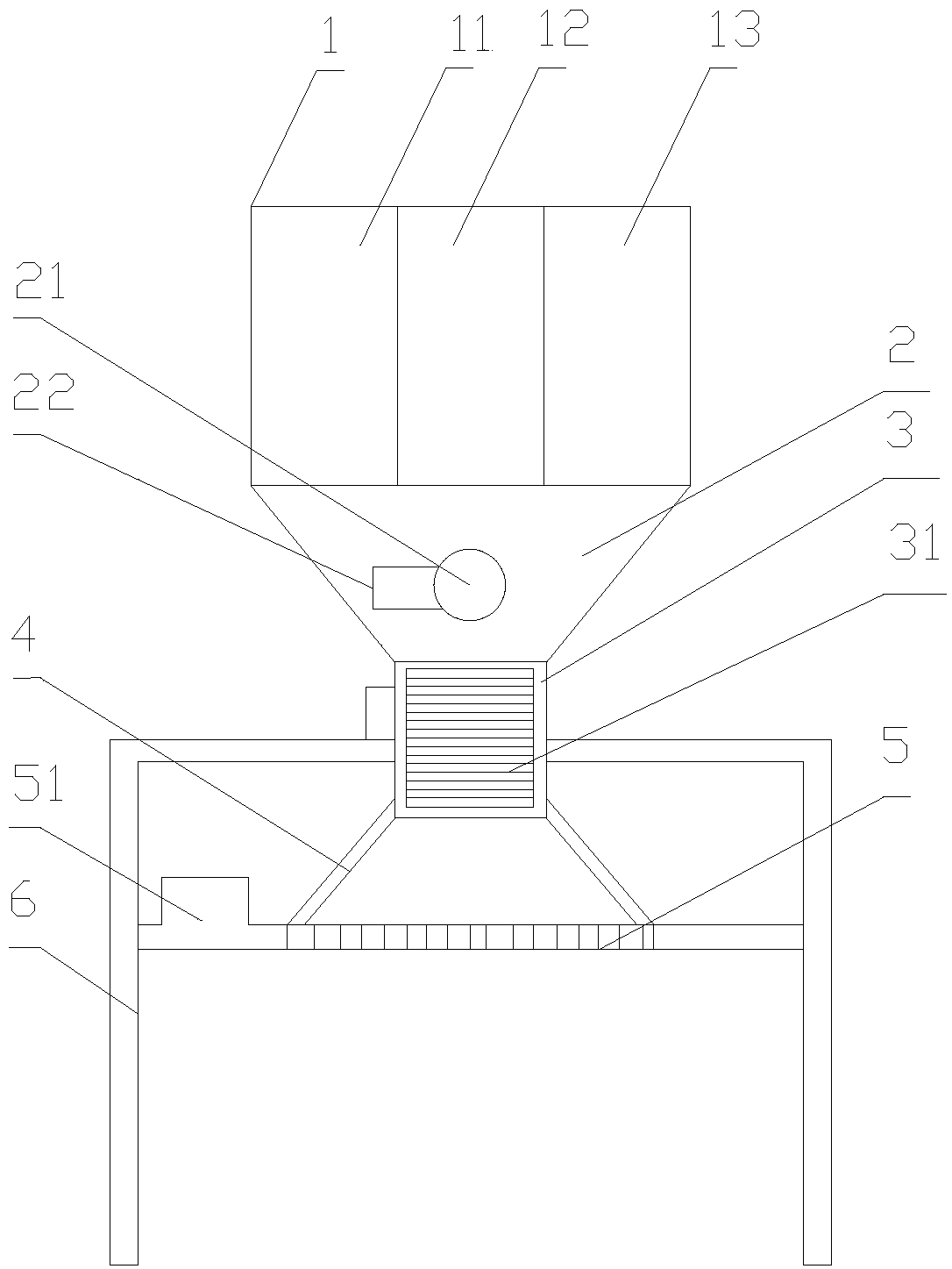

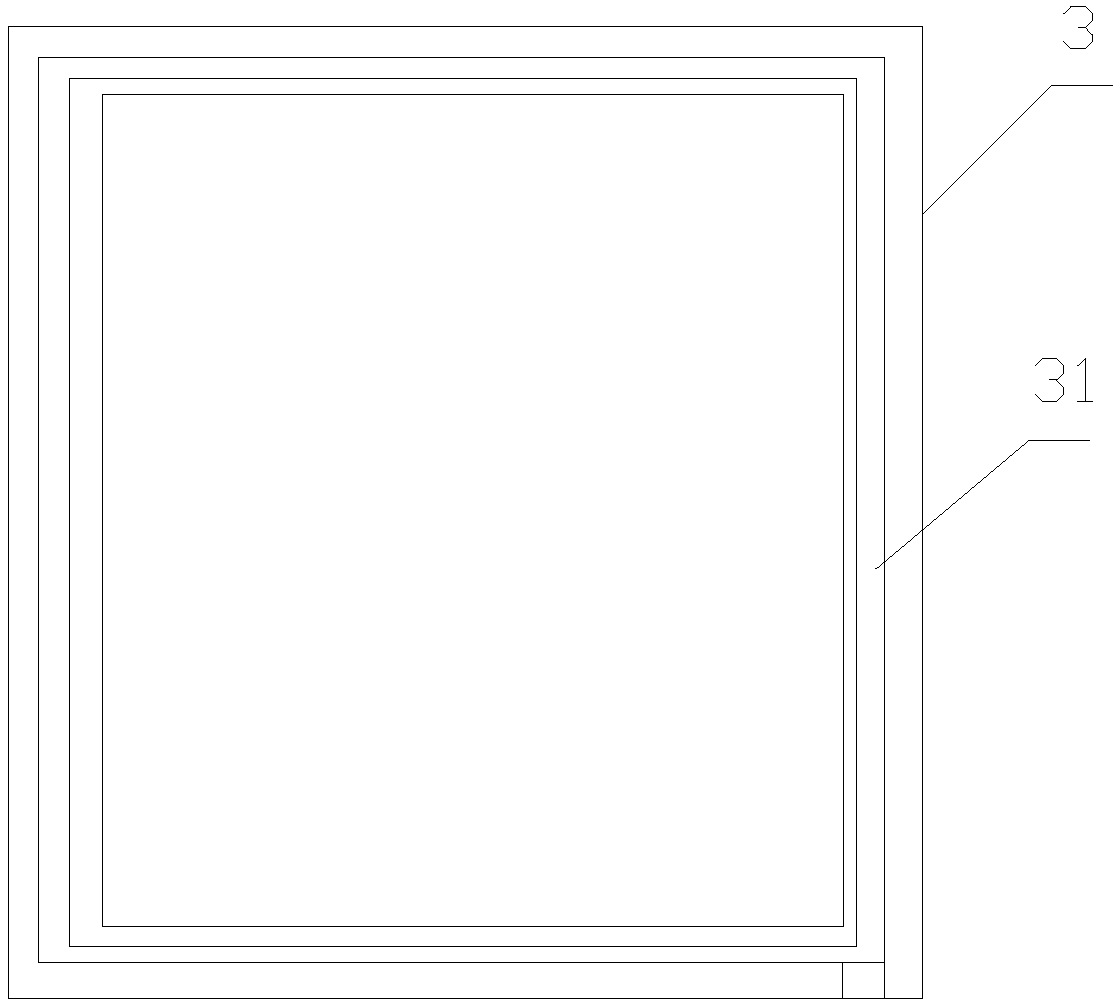

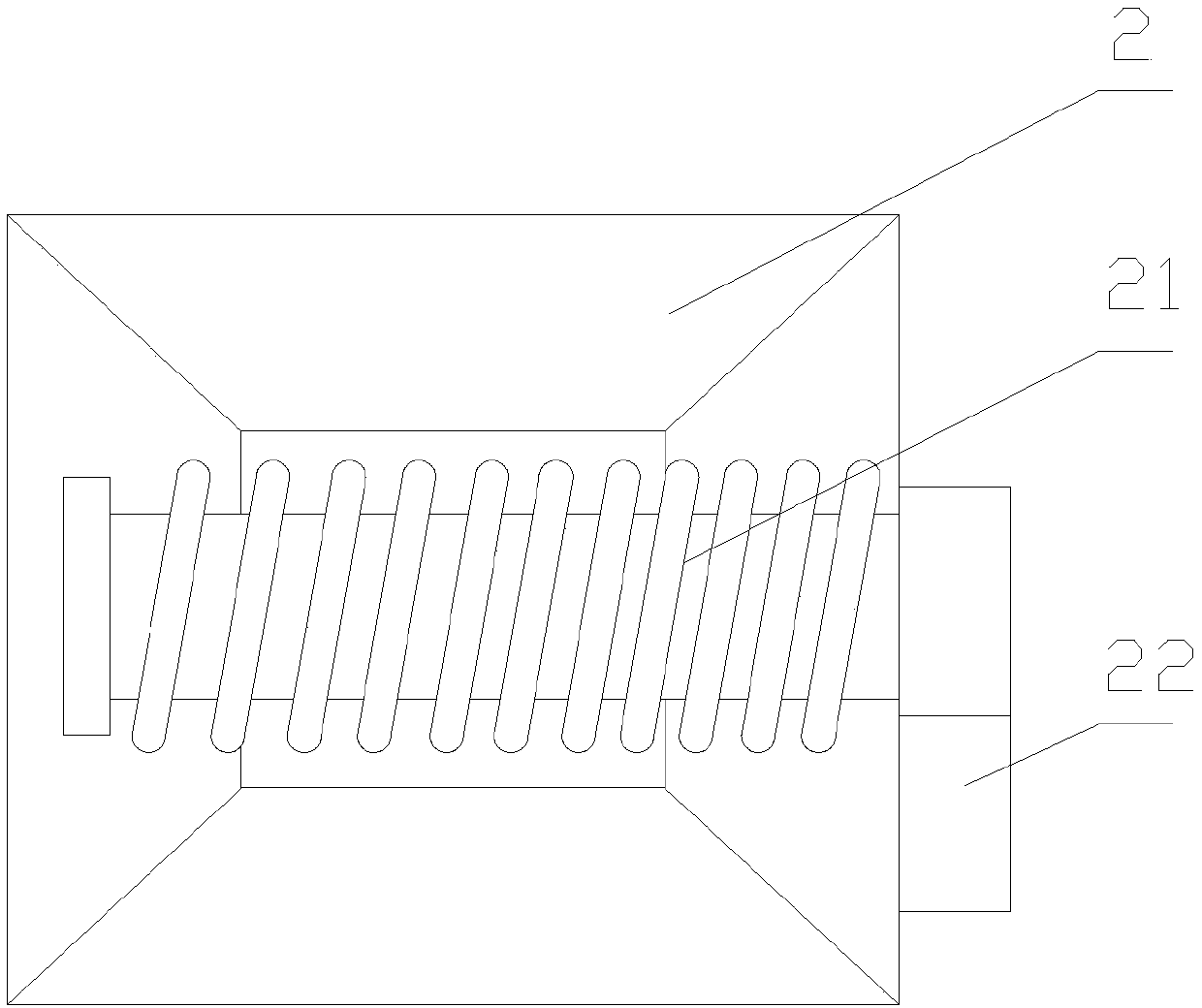

[0041] Such as Figure 1-Figure 3 Shown: a crushing and reuse processing device for agglomerated soil, including a feeding box 1, a funnel groove 2, a heat treatment box 3, a dispersion box 4 and a vibrating sieve tray 5, wherein the feeding box 1 is a rectangular structure, and the feeding box 1 is provided with The first feed pipe 11, the second feed pipe 12 and the third feed pipe 12 are equipped with a funnel groove 2 of conical structure at the bottom of the feeding box 1, and a crushing rod 21 is horizontally installed in the funnel groove 2, and at the bottom of the funnel groove 2 A heat treatment box 3 is installed at the bottom, and the inside of the heat treatment box 3 is a hollow body structure. The top of the heat treatment box 3 is open and is sealed and connected with the bottom outlet of the funnel groove 2. A dispersion box 4 is installed at the bottom of the heat treatment box 3. A vibrating sieve tray 5 is installed horizontally at the bottom;

[0042] The...

Embodiment 2

[0049] Such as Figure 1-Figure 3 Shown: During the use of the whole equipment, the feeding box 1 on the top can simultaneously add and mix soil blocks and other additives through the first material pipe 11, the second material pipe 12 and the third material pipe 12 inside, After the mixed soil block enters the funnel groove 2, the soil block is crushed spirally by the smashing rod 21 in the funnel groove 2, and then crushed and stirred with the additives or modifiers added at the same time to make it more mixed. Evenly, then the soil will be heated up through the heat treatment box 3, and the heated soil will fall into the vibrating sieve plate 5 through the dispersion plate 4 for screening and refinement;

[0050] After the whole set of process treatment, the agglomerated soil can be crushed, and modifiers can be added to modify the soil, and then the temperature is raised when passing through the heat treatment box 3 to increase the activity of the soil and the modifier, so...

Embodiment 3

[0052] When using this patented equipment to improve the soil, it is also necessary to match the modifier and the soil to pass through the crushing equipment. The modifier used is prepared from the following components in parts by mass:

[0053] 20 parts of diatom mud, 8 parts of red date powder, 8 parts of apple cider vinegar, 5 parts of melon seed gold, 3 parts of tea leaves, 6 parts of winter melon skin, 6 parts of plant ash, 8 parts of straw, 10 parts of livestock and poultry manure, 5 parts of calcite powder, 6 parts of squid bone, 5 parts of Bupleurum, 8 parts of potassium fertilizer, 10 parts of willow leaves, 2 parts of accelerator, 1 part of auxiliary agent;

[0054] Accelerator comprises 15 parts of baking soda, 5 parts of glycerin, 10 parts of Poria cocos powder, 5 parts of fly ash, 5 parts of calamine according to parts by weight;

[0055] The straw is one or more of corn straw, wheat straw, rice straw, and sorghum straw, and the corn straw, wheat straw, rice straw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com