Process for preparing magnesium alloy with layered gradient structure

A gradient structure and preparation technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of reducing material plasticity, restricting the rapid development of the magnesium alloy industry, and unfavorable processing and deformation, so as to improve material strength, Improved comprehensive mechanical properties and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

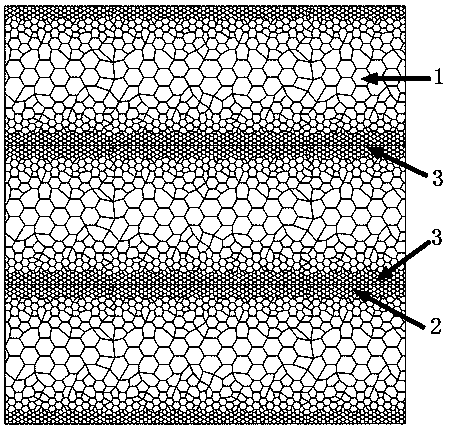

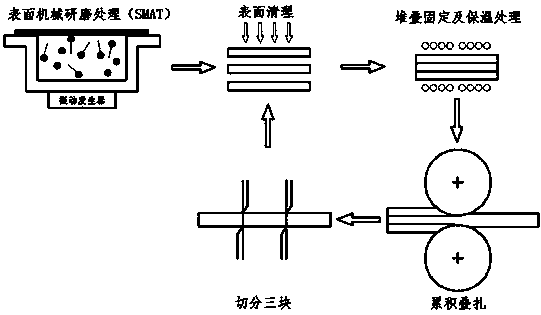

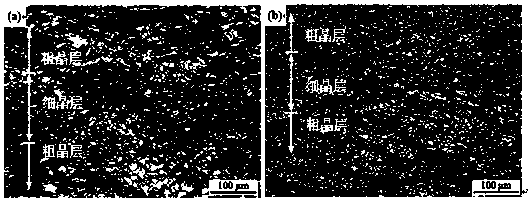

[0027] The invention discloses a preparation process of a layered gradient structure magnesium alloy, which comprises the following steps:

[0028] a. Select two or more magnesium alloy plates of the same specification, and carry out surface mechanical grinding treatment on each magnesium alloy plate; in the present embodiment, what is selected is three AZ31 magnesium alloy plates; in order to avoid deformation, the front and back sides are alternately processed method, the single processing time for one side is 10s, and the cumulative processing time for one side is 4min.

[0029] b. Clean the bonding surface of each AZ31 magnesium alloy plate with a wire brush and acetone, remove the oxide layer and dirt, and rinse with deionized water;

[0030] c. Stack the processed plates together and make them tightly bonded, with no relative movement between the plates as the standard; this embodiment uses thin copper wires to bind and fix the three plates, and other forms of the prior ...

Embodiment 2

[0037] a. Select three AZ31 magnesium alloy plates and perform mechanical grinding on the surface of each plate; in order to avoid deformation, the front and back sides are treated alternately. The single treatment time for one side is 30s, and the cumulative treatment time for one side is 10 minutes;

[0038] b. Clean the bonding surface of each AZ31 magnesium alloy plate with a wire brush and acetone, remove the oxide layer and dirt, and rinse with deionized water;

[0039] c. Stack the treated plates together and make them tightly bonded, with no relative movement between the plates as the standard;

[0040] d. Put the stacked plates into the incubator, and keep warm for 30 minutes after rising to the set 150°C;

[0041] e. Take out the plate and put it into the rolling mill immediately for rolling with a reduction of 30%, that is to say, complete one stack rolling;

[0042] f. Air cooling;

[0043] g. Cut the rolled and cooled plate into equal parts, cut into three piece...

Embodiment 3

[0047] a. Select three AZ91 magnesium alloy plates and perform surface mechanical grinding treatment on each plate; in order to avoid deformation, adopt the method of alternating front and back sides. The single treatment time for one side is 20s, and the cumulative treatment time for one side is 7 minutes;

[0048] b. Clean the bonding surface of each AZ91 magnesium alloy plate with a wire brush and acetone, remove the oxide layer and dirt, and rinse with deionized water;

[0049] c. Stack the treated plates together and make them tightly bonded, with no relative movement between the plates as the standard;

[0050] d. Put the stacked plates into the incubator, and keep warm for 10 minutes after rising to the set 450°C;

[0051] e. Take out the plate and put it into the rolling mill immediately for rolling with a reduction of 50%, that is to say, complete one stack rolling;

[0052] f. Air cooling;

[0053] g. Cut the rolled and cooled plate into equal parts, cut into three p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com