Preparation method of surface-carboxylation gold magnetic core shell nano-composite particles

A composite nanoparticle and nanoparticle technology, applied in the field of biomedical engineering, can solve problems such as no functional groups, and achieve the effects of good biocompatibility, dispersion stability, good biological functionality and multiple responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

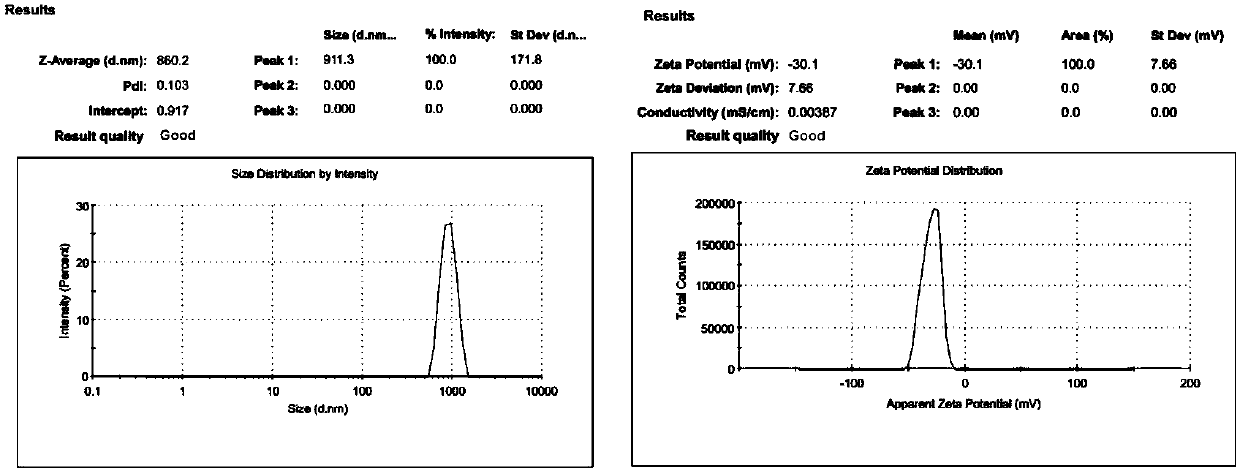

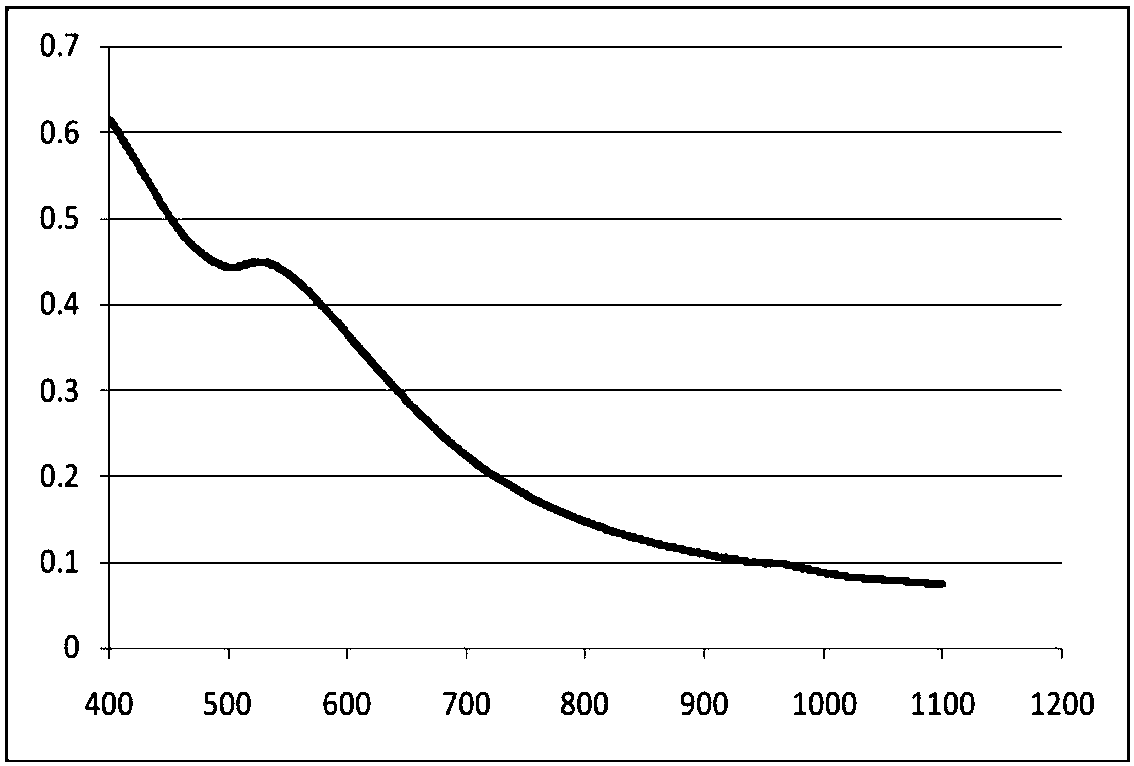

[0025] A method for preparing surface carboxylated gold magnetic core-shell composite nanoparticles, comprising the steps of:

[0026] (1) Fe 3 o 4 Preparation of nanoparticles: 1.156g FeCl 3 ·6H 2O, 3.3012g of ammonium acetate, 0.3424g of trisodium citrate were dissolved in 60mL of ethylene glycol, and kept for 1 hour when heated to 170°C; after cooling to room temperature, the solution was transferred to the reactor and reacted at 200°C for 8 hours; After the end, perform magnetic separation, wash with absolute ethanol and water alternately for 3 times, and finally disperse in absolute ethanol.

[0027] (2) Fe 3 o 4 Surface modification of nanoparticles: ① Put 1.96g of maleic anhydride (maleic anhydride) in a 10mL round-bottomed flask, add 3.4mL of APTES dropwise under the condition of ice-water bath, put it into the rotor and stir, and wait until the reactants become into a white solid (APTES-COOH) to stop the reaction; ② Take 30mg Fe 3 o 4 Add the absolute ethanol ...

Embodiment 2

[0033] A method for preparing surface carboxylated gold magnetic core-shell composite nanoparticles, comprising the steps of:

[0034] (1) Fe 3 o 4 Preparation of nanoparticles: 1.156g FeCl 3 ·6H 2 O, 3.3012g of ammonium acetate, 0.3424g of trisodium citrate were dissolved in 60mL of ethylene glycol, and kept for 1 hour when heated to 170°C; after cooling to room temperature, the solution was transferred to the reactor and reacted at 200°C for 16 hours; After the end, perform magnetic separation, wash 4 times with absolute ethanol and water, and finally disperse in absolute ethanol.

[0035] (2) Fe 3 o 4 Surface modification of nanoparticles: ① same as Example 1; ② take 30mg Fe 3 o 4 Add the absolute ethanol solution of nanoparticles and 1mL ammonia water to 100mL absolute ethanol, disperse evenly and place in a water bath at 40°C for reaction; add 45μL TEOS and react for 2h; add 30mg APTES-COOH and react for another 7h to end the reaction. Magnetic separation or centr...

Embodiment 3

[0041] A method for preparing surface carboxylated gold magnetic core-shell composite nanoparticles, comprising the steps of:

[0042] (1) Fe 3 o 4 Preparation of nanoparticles: 1.156g FeCl 3 ·6H 2 O, 3.3012g of ammonium acetate, 0.3424g of trisodium citrate were dissolved in 60mL of ethylene glycol, and kept for 1 hour when heated to 170°C; after cooling to room temperature, the solution was transferred to a reaction kettle and reacted at 200°C for 10 hours; After the end, perform magnetic separation, wash with absolute ethanol and water alternately for 3 times, and finally disperse in absolute ethanol.

[0043] (2) Fe 3 o 4 Surface modification of nanoparticles: ① same as Example 1; ② take 30mg Fe 3 o 4 Add the absolute ethanol solution of nanoparticles and 2mL ammonia water to 100mL absolute ethanol, disperse evenly and place in a water bath at 40°C for reaction; add 30μL TEOS and react for 2h; add 60mg APTES-COOH and react for another 7h to end the reaction. Magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com