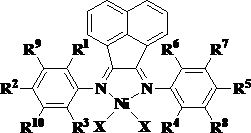

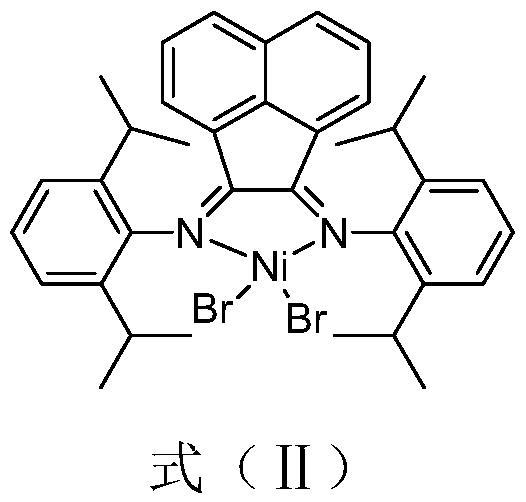

Catalyst composition for long-chain α-olefin polymerization and method for catalyzing long-chain α-olefin polymerization

A technology of olefin polymerization and catalyst, which is applied in the field of olefin polymerization catalysts, and can solve the problems of poor thermal stability and high molecular weight of catalyzed long-chain α-olefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Vacuumize the 100ml three-necked reaction flask, replace it with nitrogen three times, add 7.2mg (10μmol) complex 3, 15ml 1-decene, 0.8ml methylaluminoxane (MAO) (1.53mol / l toluene solution) , 0.5ml of diethylzinc (1.0mol / l toluene solution), the polymerization reaction stopped after 2 hours at 60°C, and the reaction system was black and viscous. Terminate the reaction with dilute hydrochloric acid-ethanol solution, dissolve the obtained polymer in tetrahydrofuran, precipitate in methanol, repeat this process three times, and finally put the sample in a vacuum drying oven for 24 hours to obtain 1.67g of a white solid polymer with certain elasticity . The catalytic efficiency of the catalytic system is 167kg mol -1 Ni, the weight-average molecular weight of the polymer measured at the end of the reaction was Mw=169,800, and the molecular weight distribution Mw / Mn=2.31.

Embodiment 2

[0058] Vacuumize the 100ml three-necked reaction flask, replace it with nitrogen three times, add 7.2mg (10μmol) complex 3, 15ml 1-decene, 0.8ml methylaluminoxane (MAO) (1.53mol / l toluene solution) , 1.0ml of diethylzinc (1.0mol / l toluene solution), the polymerization reaction stopped after 2 hours at 60°C, and the reaction system was black and viscous. The reaction was terminated with dilute hydrochloric acid-ethanol solution, the obtained polymer was dissolved in tetrahydrofuran, and methanol was precipitated. This was repeated three times. Finally, the sample was dried in a vacuum oven for 24 hours to obtain 1.82 g of a polymer with certain elasticity. The catalytic efficiency of the catalytic system is 182kgmol -1 Ni, the weight-average molecular weight of the polymer measured at the end of the reaction was Mw=108,800, and the molecular weight distribution Mw / Mn=2.06.

Embodiment 3

[0060] Vacuumize the 100ml three-necked reaction flask, replace it with nitrogen three times, add 7.2mg (10μmol) complex 3, 15ml 1-decene, 0.8ml methylaluminoxane (MAO) (1.53mol / l toluene solution) , 2.0ml of diethylzinc (1.0mol / l toluene solution), the polymerization reaction stopped after 2 hours at 60°C, and the reaction system was black and viscous. The reaction was terminated with dilute hydrochloric acid-ethanol solution, the obtained polymer was dissolved in tetrahydrofuran, and methanol was precipitated. This was repeated three times. Finally, the sample was dried in a vacuum oven for 24 hours to obtain 1.04 g of a polymer with certain elasticity. The catalytic efficiency of the catalytic system is 104kgmol -1 Ni, the weight-average molecular weight of the polymer measured at the end of the reaction was Mw=52,400, and the molecular weight distribution Mw / Mn=1.87.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com