Preparation method of tea-oil tree fruit shell anti-enteritis micro-capsule and product and application thereof

A technology of Camellia oleifera husk and enteritis, which is applied in the field of medicine, can solve problems such as no related reports, and achieve the effects of simple preparation process, convenient industrial production, and enhanced drug effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

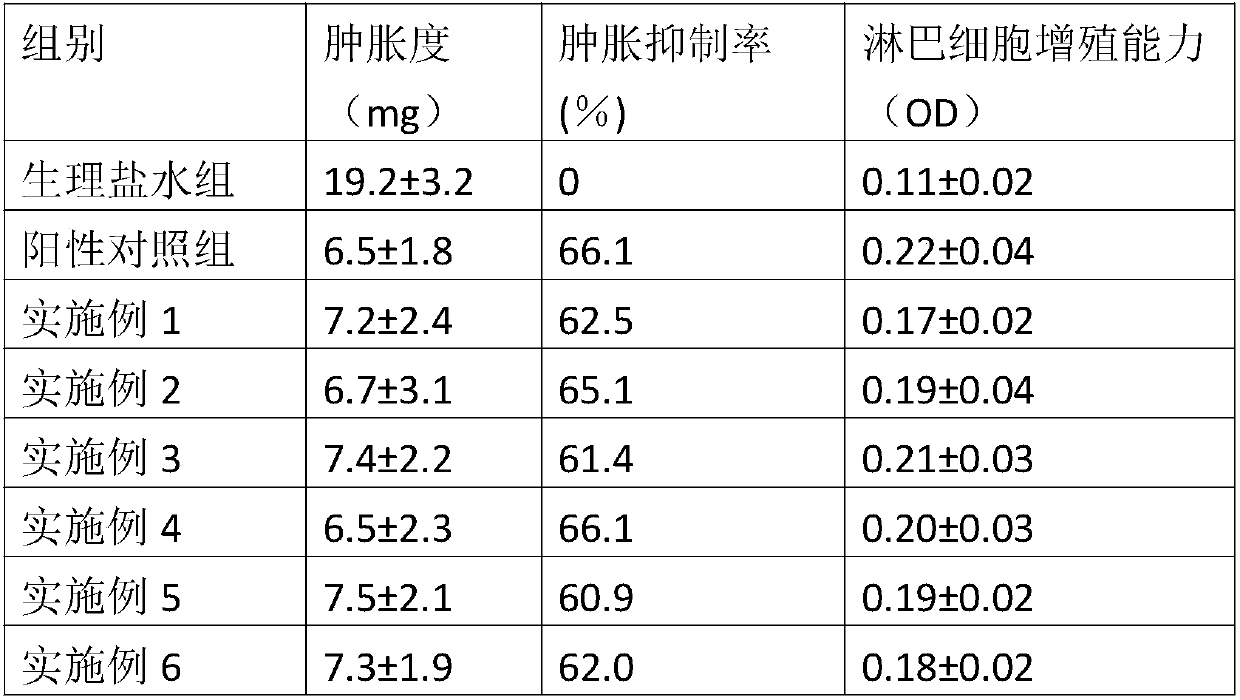

Examples

Embodiment 1

[0023] The preparation method of camellia oleifera husk anti-enteritis microcapsules, the steps are:

[0024] A. Add 1 kg of Camellia oleifera husk to 0.5 kg of 85% (V / V) ethanol aqueous solution, 500W ultrasonic treatment at room temperature for 1 h, filter, and the filtrate is adsorbed for 24 h through 0.5 kg of D101 macroporous resin, and washed with 65% (V / V) ) was eluted with an ethanol aqueous solution, and dried under reduced pressure at 0.01 MPa at 50°C for 3 hours to obtain 110 g of tannin in camellia oleifera husk;

[0025] B. Add 5g of tea tree oil, 5g oregano oil, 500g of 10% (g / mL) acrylic resin II and acrylic resin III mixed acetone solution in 100g Camellia oleifera husk tannin, the mixture of acrylic resin II and acrylic resin III The mass ratio is 1:1, stirred at 800 rpm for 90 min, then dropped into liquid paraffin whose volume is 3 times the system volume, and stirred at 800 rpm for 90 min;

[0026] C. Stand for stratification, remove the liquid layer, rins...

Embodiment 2

[0028] The preparation method of camellia oleifera husk anti-enteritis microcapsules, the steps are:

[0029] A. Add 1kg camellia oleifera husk to 3kg of 50% (V / V) ethanol aqueous solution, 50W ultrasonic treatment at room temperature for 5h, filter, the filtrate is absorbed by 2kg of HPD100 macroporous resin for 8h, and use 40% (V / V) Eluted with aqueous ethanol solution, dried under reduced pressure at 0.1 MPa at 65°C for 4 hours, and obtained 165 g of tannin in camellia oleifera husk;

[0030] B. Add 1g tea tree oil, 1g oregano oil, 1000g 3% (g / mL) acrylic resin II and acrylic resin III mixed acetone solution to 100g Camellia oleifera husk tannin, the mixture of acrylic resin II and acrylic resin III The mass ratio is 2:1, stirred at 1000 rpm for 30 min, then dropped into liquid paraffin whose volume is 1 times the system volume, and stirred at 1000 rpm for 30 min;

[0031] C. Stand for stratification, remove the liquid layer, rinse the solid with 3 times the mass of n-hexa...

Embodiment 3

[0033] The preparation method of camellia oleifera husk anti-enteritis microcapsules, the steps are:

[0034] A. Add 1 kg of 60% (V / V) ethanol aqueous solution to 1 kg of camellia oleifera husk, 100W ultrasonic treatment at room temperature for 3 h, filter, and the filtrate is adsorbed by 1 kg of HPD400 macroporous resin for 12 h, and treated with 50% (V / V) ethanol Eluted with aqueous ethanol, dried under reduced pressure at 0.05 MPa at 60°C for 6 hours to obtain 124 g of tannin in camellia oleifera husk;

[0035] B. Add 4g of tea tree oil, 6g oregano oil, 600g of 8% (g / mL) acrylic resin II and acrylic resin III mixed acetone solution in 100g camellia oleifera husk tannin, the mixture of acrylic resin II and acrylic resin III The mass ratio is 3:1, stirred at 2000 rpm for 60 min, then dropped into liquid paraffin whose volume is 3 times the system volume, and stirred at 2000 rpm for 60 min;

[0036] C. Stand for stratification, remove the liquid layer, rinse the solid with 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com