Preparation method of silver alloy composite nanomaterial

A technology of composite nanomaterials and silver alloys, which is applied in the field of preparation of silver alloy composite nanomaterials, can solve the problems of difficulty in uniform distribution of particle size, difficulty in guaranteeing product purity, and decline in antibacterial performance, so as to achieve simple and controllable production process and excellent bactericidal performance Stable and reliable, not easy to reunite and grow up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of silver alloy copper oxide composite nanopowder, which comprises the following steps:

[0037] 1. Prepare materials.

[0038] Using 70% silver wire with a diameter of 0.5mm and a purity of 99.9%, and 30% copper wire with a diameter of 0.5mm and a purity of 99.9%, the silver and copper wires are woven into a mixed metal wire with a diameter of 8mm. Cold-rolled and rolled into metal wire rods with a diameter of 5 mm.

[0039] 2. Vaporization.

[0040] Silver and copper metal wire rods are used as anode conductors, the DC voltage is 36V, the current is 1050A, the arc length is 30mm, and the temperature is above 5000°C.

[0041] 3. Condensation.

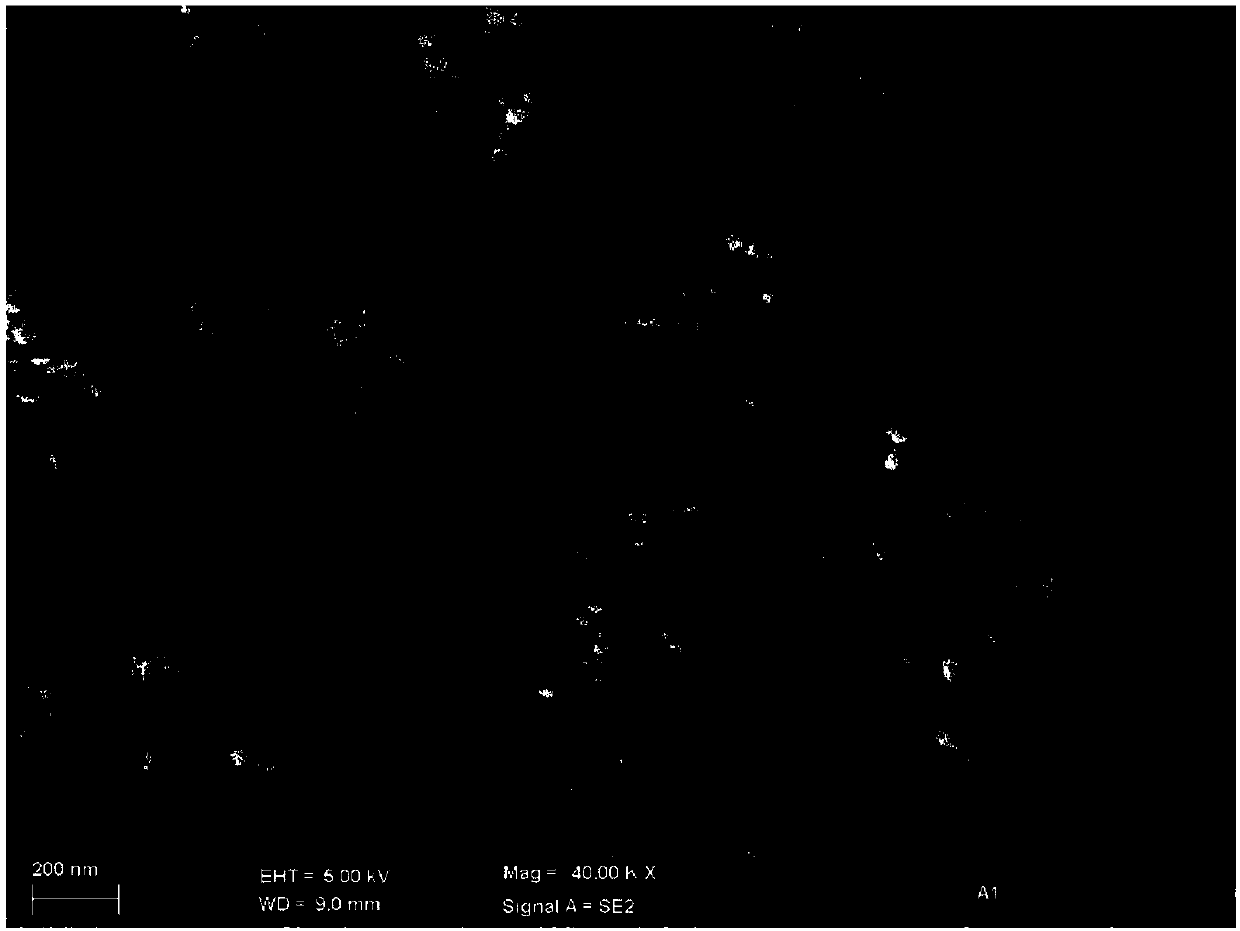

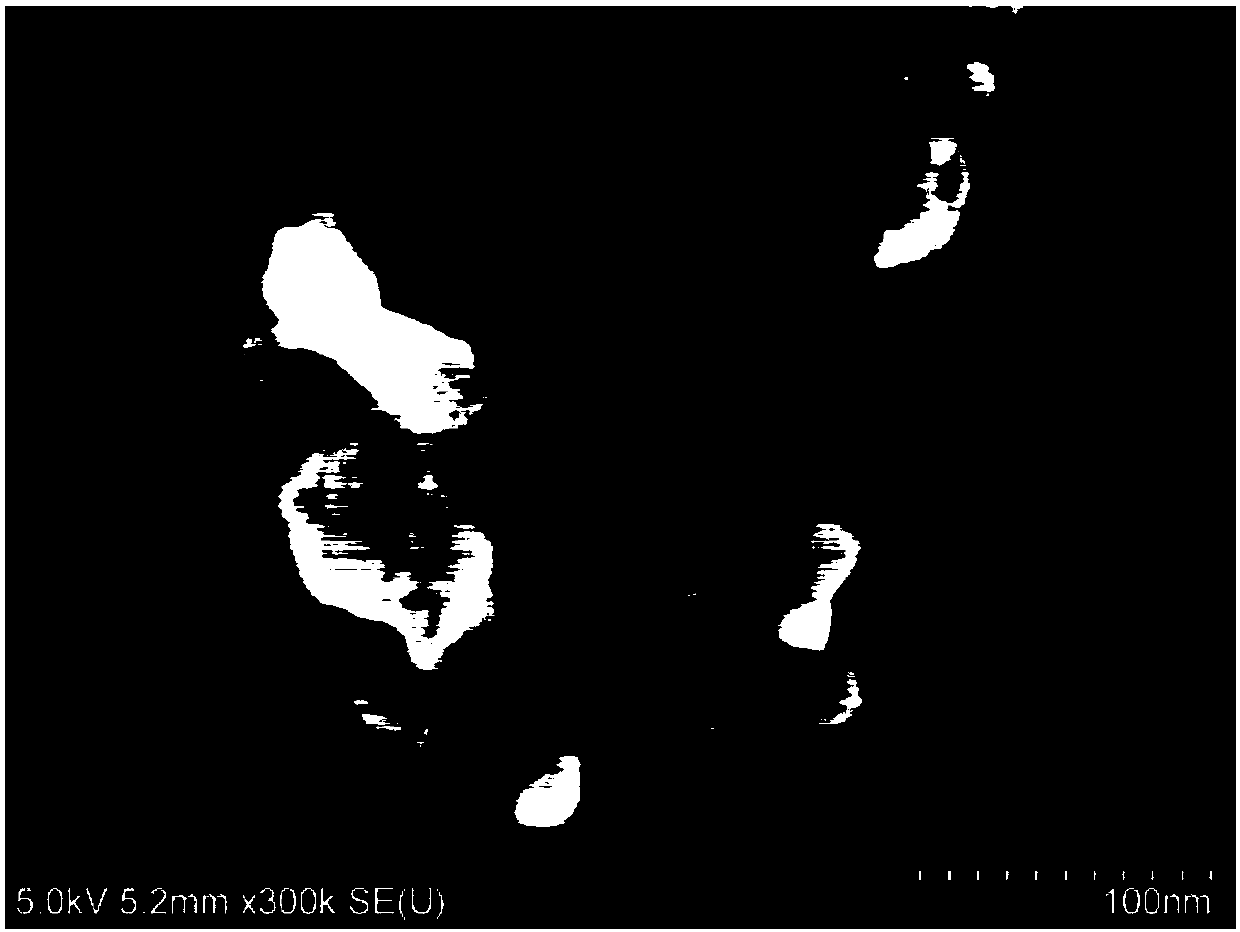

[0042] At the same time as the metal is vaporized, the gaseous alloy is separated from the high temperature area by the air flow of 1 times the speed of sound, and the gaseous alloy is rapidly cooled, so that when the metal returns to the solid state from the gaseous state, composite particles of 10nm to ...

Embodiment 2

[0048] A preparation method of silver alloy zinc oxide composite nanopowder, which comprises the following steps:

[0049] 1. Prepare materials.

[0050] Use 80% silver wire with a straight diameter of 0.5mm and a purity of 99.9%, 20% zinc wire with a diameter of 0.5mm and a purity of 99.9%, and weave the silver and zinc wires into a mixed metal wire with a diameter of 8mm. After cold rolling and calendering, it becomes a metal wire rod with a diameter of 5mm.

[0051] 2. Vaporization.

[0052] Silver and zinc metal wire rods are used as anode conductors, the DC voltage is 32 volts, the current is 980 amps, the arc length is 28 mm, and the temperature is above 5000 ° C.

[0053]3. Condensation.

[0054] At the same time as the metal is vaporized, the gaseous alloy is separated from the high-temperature area by an air flow of 1.2 times the speed of sound, and is cooled rapidly, so that when the metal returns from the gaseous state to a solid state, composite particles of 10n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com