Polyvinylidene fluoride/polysulfonamide composite nano-fiber web and preparation method thereof

A technology of composite nanofibers and polyvinylidene fluoride, which can be used in fiber processing, spinning solution preparation, and conjugated synthetic polymer rayon filaments, etc., can solve problems such as poor UV resistance and easy breakage of amide groups. To achieve the effect of simple steps, strong operability and excellent UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

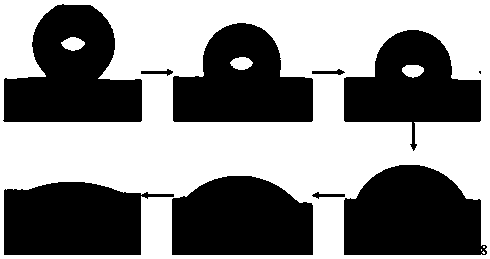

Method used

Image

Examples

Embodiment 1

[0064] (1) Configuration of polyvinylidene fluoride spinning solution:

[0065] Prepare a mixed solvent of dimethylformamide / acetone (DMF / AC) according to a mass ratio of 7 / 3, weigh a certain amount of polyvinylidene fluoride powder and add it to the mixed solvent, mechanically stir and ultrasonically defoam to obtain a PVDF spinning solution; The content of PVDF in the PVDF spinning solution is 12wt%.

[0066] (2) Configuration of polysulfone amide spinning solution:

[0067] The 12wt% polysulfone amide spinning solution was provided by Shanghai Te Spandex Fiber Co., Ltd.

[0068] (3) Electrospinning preparation:

[0069] The above-mentioned polyvinylidene fluoride spinning solution and polysulfone amide spinning solution were mixed and stirred at a mass ratio of 7 / 3 and ultrasonically defoamed for 30 minutes; the electrospinning process was adopted, the receiving distance was set at 15 cm, and the mercury injection The pushing speed is 0.003mm / s, the electrostatic field v...

Embodiment 2

[0072] (1) Configuration of polyvinylidene fluoride spinning solution:

[0073] Prepare a mixed solvent of dimethylformamide / acetone (DMF / AC) according to a mass ratio of 7 / 3, weigh a certain amount of polyvinylidene fluoride powder and add it to the mixed solvent, mechanically stir and ultrasonically defoam to obtain a PVDF spinning solution; The content of PVDF in the PVDF spinning solution is 12wt%.

[0074] (2) Configuration of polysulfone amide spinning solution:

[0075] The 12wt% polysulfone amide spinning solution was provided by Shanghai Te Spandex Fiber Co., Ltd.

[0076] (3) Electrospinning preparation:

[0077] The above-mentioned polyvinylidene fluoride spinning solution and polysulfone amide spinning solution were mixed and stirred at a mass ratio of 5 / 5 and ultrasonically defoamed for 30 minutes; the electrospinning process was adopted, the receiving distance was set at 15 cm, and the mercury injection The pushing speed is 0.003mm / s, the electrostatic field v...

Embodiment 3

[0080] (1) Configuration of polyvinylidene fluoride spinning solution:

[0081] Prepare a mixed solvent of dimethylformamide / acetone (DMF / AC) according to a mass ratio of 7 / 3, weigh a certain amount of polyvinylidene fluoride powder and add it to the mixed solvent, mechanically stir and ultrasonically defoam to obtain a PVDF spinning solution; The content of PVDF in the PVDF spinning solution is 12wt%.

[0082] (2) Configuration of polysulfone amide spinning solution:

[0083] The 12wt% polysulfone amide spinning solution was provided by Shanghai Te Spandex Fiber Co., Ltd.

[0084] (3) Electrospinning preparation:

[0085] The above-mentioned polyvinylidene fluoride spinning solution and polysulfone amide spinning solution were mixed and stirred at a mass ratio of 3 / 7 and ultrasonically defoamed for 30 minutes; the electrospinning process was adopted, the receiving distance was set at 15 cm, and the mercury injection The pushing speed is 0.003mm / s, the electrostatic field v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com