A kind of preparation method of branch-shaped nanomaterial containing copper and non-noble metal

A non-precious metal and nano-material technology, applied in the field of branch-like nano-materials and its preparation, can solve the problems of complex reaction equipment, long reaction time, unfavorable production, etc., and achieve the effect of simple process, simple operation steps and low time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Add soluble starch (potato starch, the same as in the following examples) to 1L of aqueous solution so that its concentration is 2 grams of soluble starch per 100 milliliters of water. Stir in an oil bath with a condensation reflux device and heat up Incubate at 95°C for 15 minutes, cool down to room temperature, and set aside;

[0037] (2) Take 10 mL of the starch solution obtained in step (1), add 19.55 mg (0.082 mmol) of cobalt chloride and 10.15 mg (0.043 mmol) of copper chloride, and ultrasonically (frequency is 40 Hz) at 25 ° C for 5 minutes to make the chloride Cobalt and copper chloride are evenly distributed in the starch solution;

[0038] (3) Add 2.68 mg of sodium borohydride to the solution in step (2) for ultrasonic reaction for two minutes;

[0039] (4) Transfer the solution after the reaction in step (3) to a centrifuge tube, centrifuge at room temperature (10000r / min), wash with water three times, pour off the supernatant, and put the precipitate in...

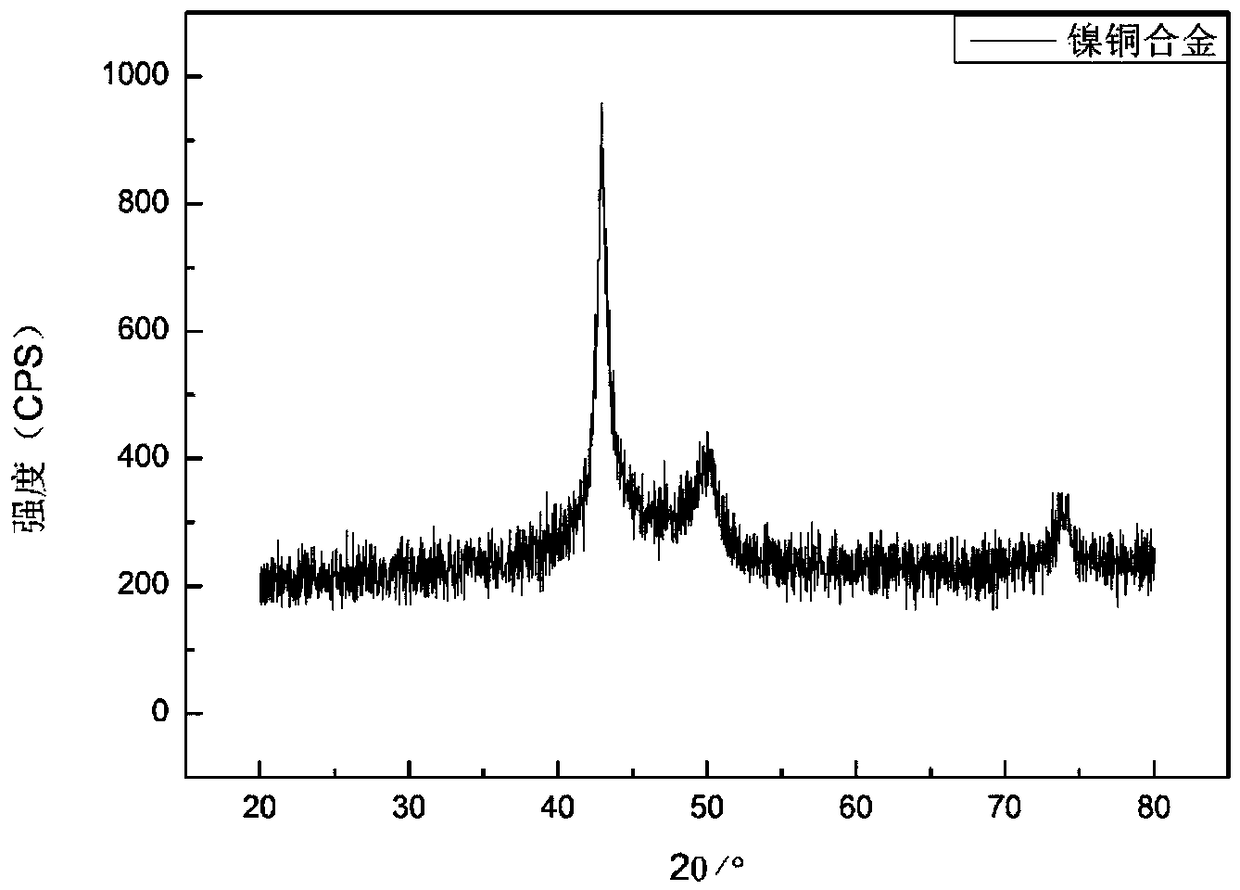

Embodiment 10

[0047] (1) Add soluble starch to 1L of aqueous solution so that the concentration is 2 grams of soluble starch per 100 ml of water, put it into an oil bath with a condensation reflux device and stir, heat up to 95°C and keep it for 15 minutes, then drop to room temperature, spare;

[0048] (2) Take 10 mL of the starch solution obtained in step (1), add 14.57 mg of nickel chloride and 15.13 mg of copper chloride, and ultrasonically (frequency is 40 Hz) at 25 ° C for 5 minutes to make nickel chloride and copper chloride in the starch solution evenly distributed in

[0049] (3) Add 2.68 mg of sodium borohydride to the solution in step (2) for ultrasonic reaction for two minutes;

[0050] (4) Transfer the solution after the reaction in step (3) to a centrifuge tube, centrifuge at room temperature, wash with water and three times, pour off the supernatant, and freeze in the refrigerator for 1 hour;

[0051] (4) Take the centrifuge tube out of the refrigerator and place it in a va...

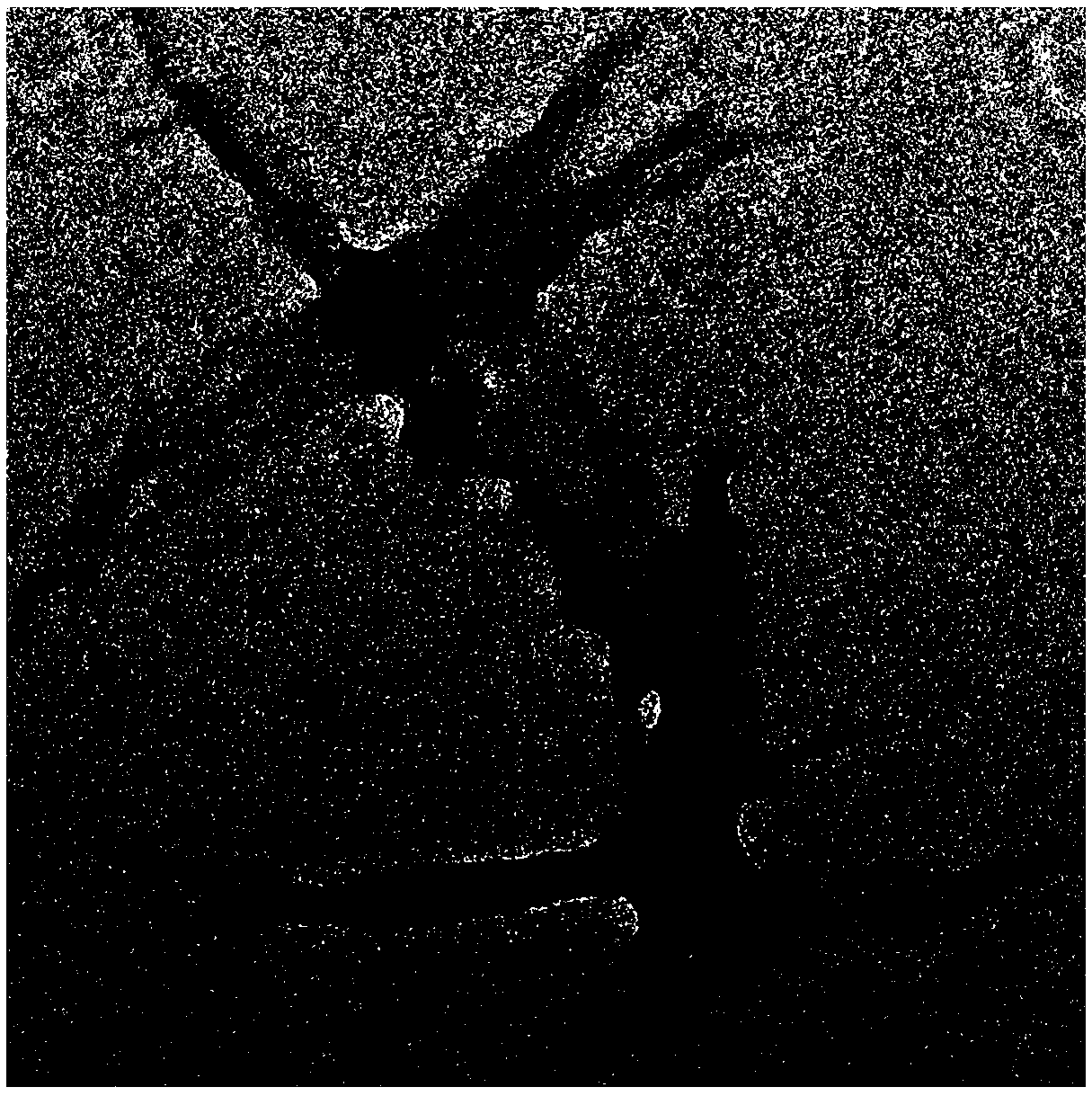

Embodiment 19

[0058] (1) 9.975 mg of nickel chloride, 9.975 mg of cobalt chloride and 1.015 mg of copper chloride were added to 10 mL of starch solution, and ultrasonicated for 5 minutes, so that the cobalt chloride and copper chloride were evenly distributed in the starch solution;

[0059] (2) Add 0.0268 gram of sodium borohydride to the solution and react for 2 minutes;

[0060] (3) Transfer the reacted solution to a centrifuge tube, centrifuge, wash with water and alcohol for 3 times, pour off the supernatant, and put it in the refrigerator to freeze for 1 hour;

[0061] (4) Take the centrifuge tube out of the refrigerator and place it in a vacuum freeze-drying machine, wait for the liquid to be drained and take out the sample to obtain a dendritic cobalt-copper nanostructure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com