Gas-electric hybrid type gas-based shaft furnace reduction system and method

A gas-based shaft furnace and hybrid technology, applied in the field of metallurgy, can solve the problems of difficult to further increase reduction temperature, increase equipment investment, long reduction time, etc., and achieve the effects of prolonging reduction reaction time, saving equipment volume and fast reaction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

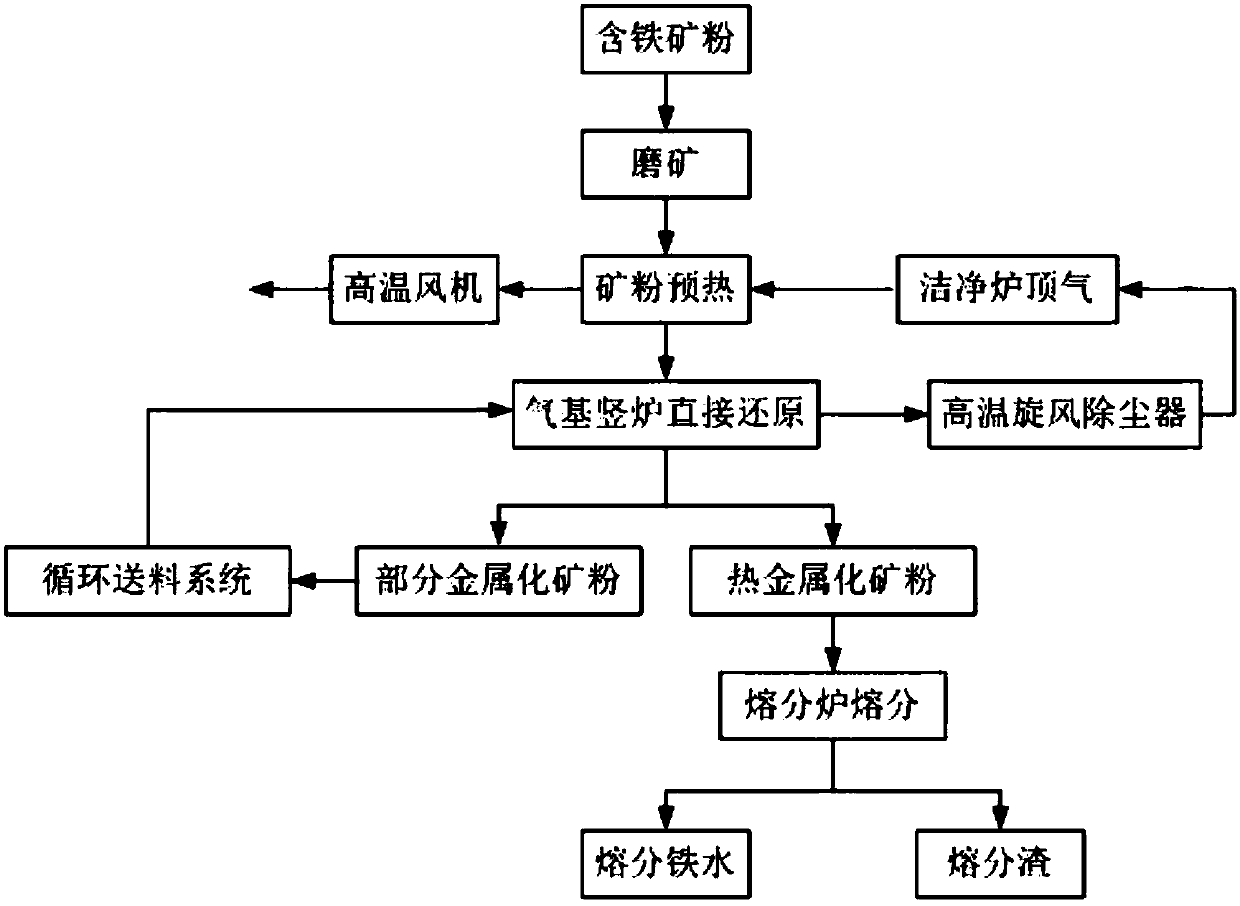

[0055] 1) transport the ore powder to the silo, and send the ore powder in the silo to the preheating bin for preheating, and the particle size of the ore powder is 100 mesh, accounting for more than 80%;

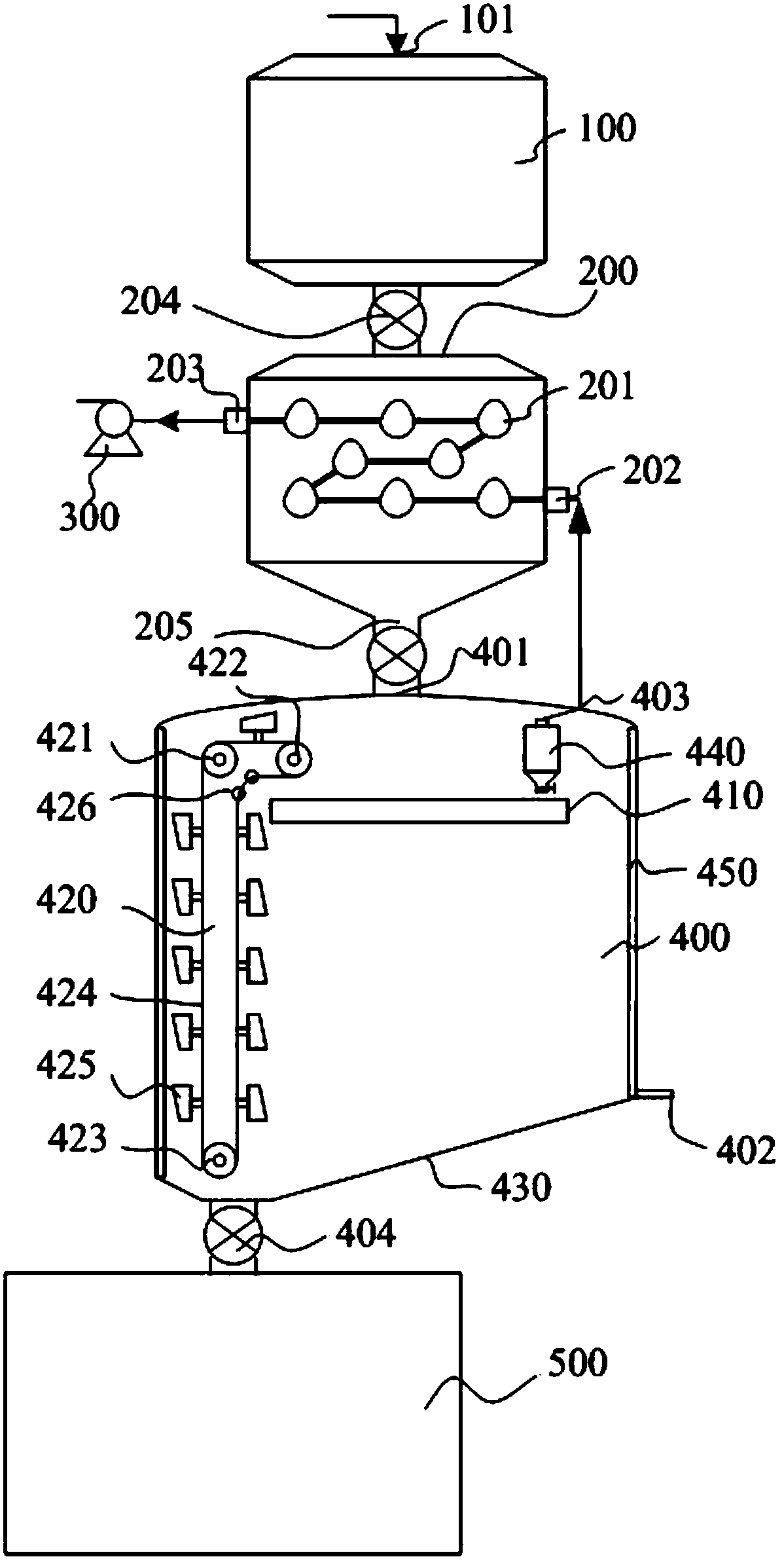

[0056] 2) The preheated ore powder is sent to the gas-electric hybrid gas-based shaft furnace, and at the same time, the driving device outside the shaft furnace is started to control the drive roller to drive the chain and the hopper to move;

[0057] 3) The ore powder falls through the distributor, and the reducing gas is input from the lower part of the gas-based shaft furnace. The falling ore powder and the rising reducing gas undergo a reduction reaction to form incomplete metallized materials, which are passed through the guide material. The grooves converge to the lower part of the circulating feeding device, and the hopper of the circulating feeding device transfers part of the metallized material to the distributor for secondary distribution, and then undergoes a re...

Embodiment 2

[0060] 1) Transport the ore powder to the silo, and send the ore powder in the silo to the preheating bin for preheating, and the particle size of the ore powder is 100 mesh, accounting for more than 90%;

[0061] 2) The preheated ore powder is sent to the gas-electric hybrid gas-based shaft furnace, and at the same time, the driving device outside the shaft furnace is started to control the drive roller to drive the chain and the hopper to move;

[0062] 3) The ore powder falls through the distributor, and the reducing gas is input from the lower part of the gas-based shaft furnace. The falling ore powder and the rising reducing gas undergo a reduction reaction to form incomplete metallized materials, which are passed through the guide material. The grooves converge to the lower part of the circulating feeding device, and the hopper of the circulating feeding device transfers part of the metallized material to the distributor for secondary distribution, and then undergoes a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com