Compound purple cereal fermented milk containing dietary fiber and preparation method of compound purple cereal fermented milk

A dietary fiber and purple technology, applied to bacteria used in food preparation, dairy products, food science, etc., can solve the problems of rough taste of grain raw materials, few types of grain raw materials, and bad flavor of products, so as to enhance human immune function , Rich colors, outstanding health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

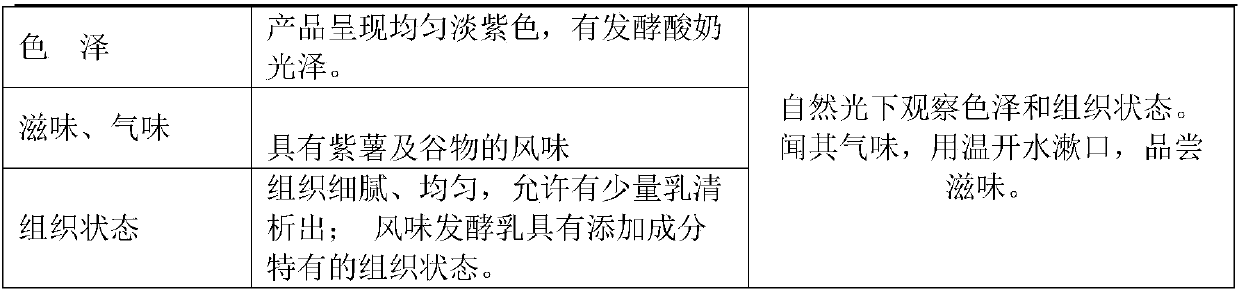

Embodiment 1

[0037] A purple grain fermented milk product containing dietary fiber and probiotics, the milk is first screened, and then the grain raw materials are processed in the steps of dissolving, grinding, gelatinization, enzymatic hydrolysis, and homogenization, the screened milk, the processed grains The slurry is mixed with a stabilizer and then homogenized, sterilized, inoculated, fermented, demulsified, refrigerated, filled, and post-fermented. %, purple rice flour 0.5%, soybean protein 0.4%, liquid milk 88%, white sugar 7.8%, emulsification stabilizer 0.5%, strain 0.009%, polydextrose 1% and enzyme preparation 0.06%, and the rest is water.

[0038] The strains are Streptococcus thermophilus, Lactobacillus delbrueckii subsp. bulgaricus, Lactobacillus acidophilus, and Lactobacillus casei, and the ratio is 3:2:0.5:0.5.

[0039] Calculated on the basis of 1 kg of fermented milk, the emulsion stabilizer includes the following components: 2 g of emulsifying thickener, 8 g of hydroxypro...

Embodiment 2

[0060] A compound purple grain fermented milk product containing dietary fiber, the formula includes the following components in mass percentage: 1% purple potato flour, 0.2% purple corn flour, 0.4% purple rice flour, 0.2% soybean protein, and 80% liquid milk , 6% white sugar, 1% emulsification stabilizer, 0.05% ethyl maltol, 0.04% essence, 0.009% strain, 1% polydextrose and 0.05% enzyme preparation, and the rest is water.

[0061] The bacterial species are Streptococcus thermophilus, Lactobacillus delbrueckii subsp. bulgaricus, Lactobacillus acidophilus and Lactobacillus casei, wherein the ratio is 3:2:0.5:0.5; the enzyme products are cellulase, hemicellulase, Xylanase and α-amylase and glucoamylase in a ratio of 2:2:1.5:8:1.

[0062] Calculated on the basis of 1 kilogram of fermented milk product, the emulsification stabilizer includes the following mass components: the emulsification stabilizer includes the following mass components: emulsification thickener 1.5g, hydroxypr...

Embodiment 3

[0072] A compound purple grain fermented milk product containing dietary fiber, the formula includes the following components in mass percentage: 2% purple potato flour, 0.5% purple corn flour, 0.7% purple rice flour, 0.5% soybean protein, and 90% liquid milk , 8% white sugar, 1.5% emulsification stabilizer, 0.08% ethyl maltol, 0.07% essence, 0.012% strain, 1% polydextrose and 0.09% enzyme preparation, and the rest is water.

[0073] The bacterial species are Streptococcus thermophilus, Lactobacillus delbrueckii subsp. bulgaricus, Lactobacillus acidophilus and Lactobacillus casei, wherein the ratio is 3:2:0.5:0.5; the enzyme products are cellulase, hemicellulase, Xylanase and α-amylase and glucoamylase in a ratio of 2:2:1.5:8:1.

[0074] Based on 1 kg of fermented milk, the emulsion stabilizer comprises the following components: the emulsion stabilizer comprises 2.2 g of emulsifying thickener, 10.2 g of hydroxypropyl distarch phosphate, 1 g of agar, double Acetyl tartrate mon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com