Preparation method of high-efficiency D type dry powder extinguishing agent

A dry powder fire extinguishing agent and high-efficiency technology, used in fire protection equipment and other directions, can solve the problems of slow fire extinguishing speed, small application area, easy to produce re-ignition and other problems, and achieve the effect of fast fire extinguishing speed, small limitation and easy preservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

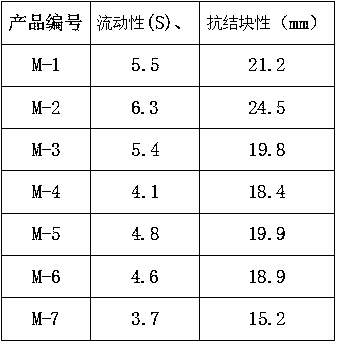

Embodiment 1

[0019] By weight, 15 parts of silicon dioxide, 60 parts of ammonium polyphosphate, 18 parts of modified sodium chloride, 0.3 part of stearic acid, 0.4 part of 4-bromo-B, B-difluorostyrene, (penta 0.03 part of (n-propylcyclopentadiene) zirconium dichloride, 0.02 part of tetrakis(trimethylsilyloxy)titanium, 0.2 part of starch, and mix the above raw materials evenly. Dry, cross-link, and solidify in a drying oven at 80°C to obtain the required fire extinguishing agent, product number M-1.

Embodiment 2

[0021] By weight, 20 parts of silicate, 70 parts of ammonium polyphosphate, 20 parts of modified potassium chloride, 0.4 part of sodium stearate, 0.5 part of 4-bromo-B, B-difluorostyrene, (five 0.05 part of methylcyclopentadiene) (n-propylcyclopentadiene) zirconium dichloride, 0.05 part of tetrakis(trimethylsiloxy)titanium, and 0.3 part of cellulose, and mix the above raw materials evenly. Dry, cross-link and solidify in a drying oven at 90°C to obtain the required fire extinguishing agent, product number M-2.

Embodiment 3

[0023] By weight, 10 parts of expanded graphite, 50 parts of ammonium polyphosphate, 15 parts of modified calcium carbonate, 0.2 part of calcium stearate, 0.1 part of 4-bromo-B, B-difluorostyrene, (pentamethyl 0.01 part of cyclopentadiene)(n-propylcyclopentadiene)zirconium dichloride, 0.01 part of tetrakis(trimethylsilyloxy)titanium, and 0.1 part of pentaerythritol, and the above raw materials were mixed uniformly. Dry, cross-link, and solidify in a drying oven at 70°C to obtain the required fire extinguishing agent, product number M-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com