Detergent for porcelain tableware

A cleaning agent and tableware technology, which is applied in the direction of detergent compounding agent, detergent composition, surface active detergent composition, etc., can solve the problems of colored glaze hazards, etc., and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

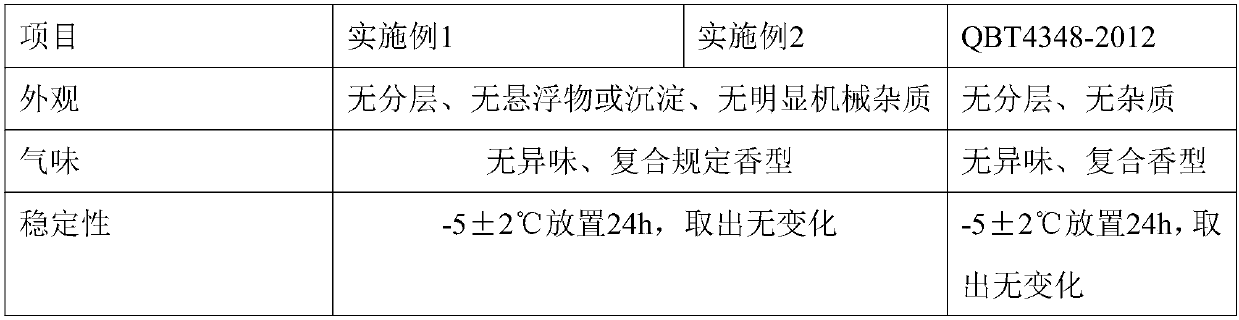

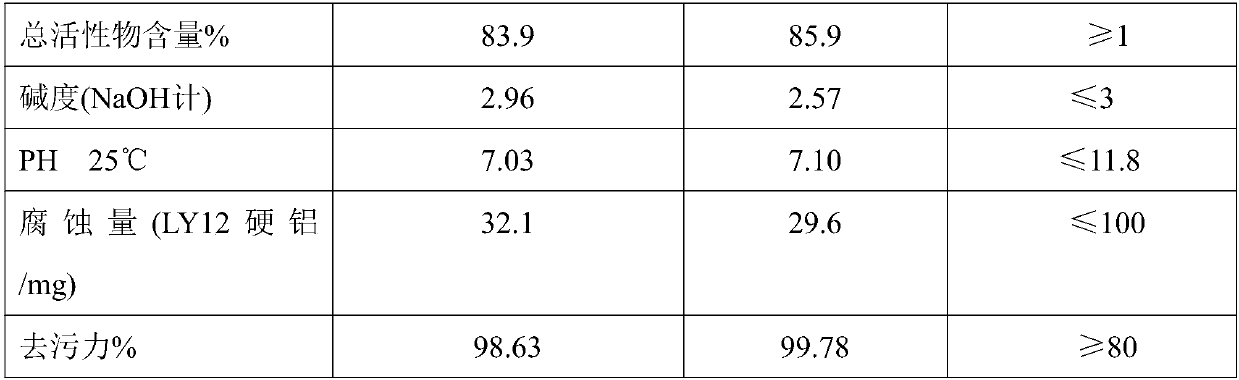

Examples

Embodiment 1

[0022] A kind of cleaning agent for porcelain tableware, its formula and preparation method are as follows:

[0023] 6 parts of rigid polyurethane foam, 7 parts of gum arabic, 2 parts of garlic oil, 3 parts of ethylparaben alcohol solution, 6 parts of geranium extract, 5 parts of mulberry fruit extract, 4 parts of chain powder, 9 parts of schisandra extract , 12 parts of mineral water, 13 parts of cornus extract, 11 parts of carboxymethyl chitosan, 10 parts of 3,4-dimethylpyrazolate, 4 parts of polyglycerol fatty acid ester, 6 parts of monoglyceride laurate 12 parts of terpene tree, 3 parts of ammonium polyphosphate, 5 parts of triphenyl phosphate, 10 parts of tung oil modified phenolic epoxy resin, 12 parts of concentrated hydrochloric acid, 0.5 parts of softener, 4.5 parts of silane, 5.5 parts of acrylic pitch resin , 10 parts of alkaline solution, and 6 parts of ethanol.

[0024] The preparation method of the tung oil modified novolac epoxy resin is as follows: the purifie...

Embodiment 2

[0035] A kind of cleaning agent for porcelain tableware, its formula and preparation method are as follows:

[0036] 7 parts of rigid polyurethane foam, 5 parts of gum arabic, 9 parts of garlic oil, 12 parts of ethylparaben alcohol solution, 6 parts of geranium extract, 7 parts of mulberry fruit extract, 10 parts of chain powder, 9 parts of schisandra extract , 19 parts of mineral water, 8 parts of cornus extract, 11 parts of carboxymethyl chitosan, 3 parts of 3,4-dimethylpyrazolate, 8 parts of polyglycerol fatty acid ester, 7 parts of monoglyceride laurate 10 parts of terpene resin, 9 parts of ammonium polyphosphate, 6 parts of triphenyl phosphate, 5 parts of tung oil modified phenolic epoxy resin, 5 parts of concentrated hydrochloric acid, 1 part of softener, 7 parts of silane, 4.5 parts of acrylic pitch resin , 10 parts of alkaline solution, and 6 parts of ethanol.

[0037] The preparation method of the tung oil modified novolac epoxy resin is as follows: the purified tung...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com