Improved method for treatment technology for secondary cobalt-nickel leaching residues

A treatment process and leaching slag technology, which is applied in the improvement field of the secondary cobalt-nickel leaching slag treatment process, can solve the problems of high labor intensity, low metal recovery rate, and high transportation costs, so as to improve the operating conditions of employees and shorten the process flow , The effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

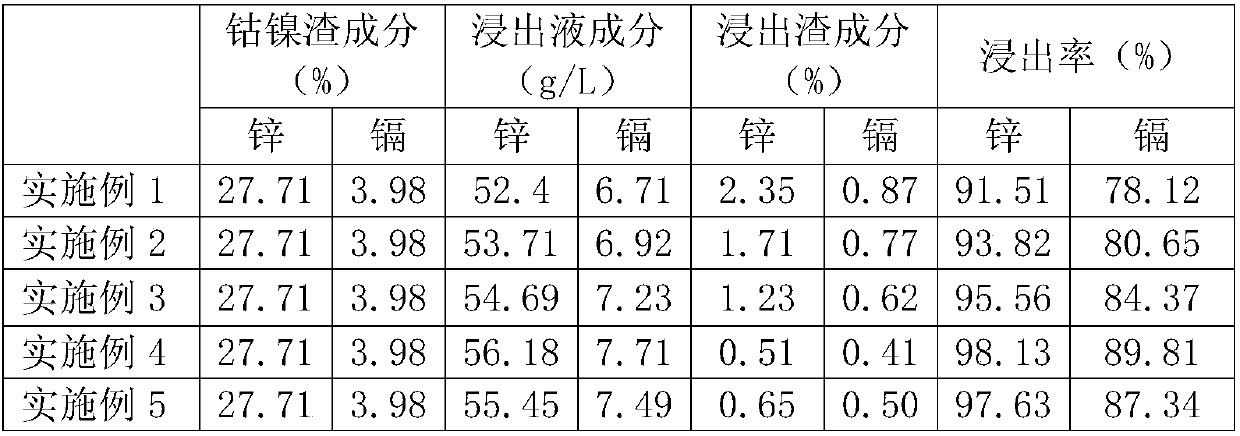

Examples

Embodiment 1

[0023] An improved method for secondary cobalt-nickel leaching slag treatment process, characterized in that: comprising the following steps:

[0024] (1) Pressure filtration: the secondary cobalt-nickel leaching residue is pumped into the filter press for pressure filtration, and the filter residue is taken for subsequent use;

[0025] (2) Slurry: take the filter residue described in step (1) and the zinc oxide leachate in the ratio of 5:1 by the liquid-solid ratio to carry out slurry, and the stirring speed is 70r / min under the condition of slurry for 30min, to obtain Slurry;

[0026] (3) Leaching: pump the slurry described in step (2) to zinc oxide high-acid leaching tanks, and add 10m 3 Slurry liquid, then add zinc electrolytic waste liquid and sulfuric acid, the acid content of zinc electrolytic waste zinc electrolytic liquid is controlled at 150g / L, leaching for 6h under the condition of liquid-solid ratio of 5:1 and temperature of 80°C, Control the initial acidity in ...

Embodiment 2

[0033] An improved method for secondary cobalt-nickel leaching slag treatment process, characterized in that: comprising the following steps:

[0034] (1) Pressure filtration: the secondary cobalt-nickel leaching residue is pumped into the filter press for pressure filtration, and the filter residue is taken for subsequent use;

[0035] (2) Slurry: take the filter residue described in step (1) and zinc oxide leachate in the ratio of 5.2:1 by liquid-solid ratio to carry out slurry, and the stirring speed is 110r / min under the condition of slurry for 30min, to obtain Slurry;

[0036] (3) Leaching: pump the slurry described in step (2) to zinc oxide high-acid leaching tanks, and add 10m 3 Slurry liquid, then add zinc electrolysis waste liquid and sulfuric acid, the acid content of zinc electrolyte waste zinc electrolysis liquid is controlled at 160g / L, leaching for 6.5h under the conditions of liquid-solid ratio of 5.5:1 and temperature of 85°C , the initial acid in the leachin...

Embodiment 3

[0043] An improved method for secondary cobalt-nickel leaching slag treatment process, characterized in that: comprising the following steps:

[0044] (1) Pressure filtration: the secondary cobalt-nickel leaching residue is pumped into the filter press for pressure filtration, and the filter residue is taken for subsequent use;

[0045] (2) Slurry: take the filter residue described in step (1) and zinc oxide leachate in the ratio of 5.6:1 by liquid-solid ratio to carry out slurry, and the stirring speed is 100r / min under the condition of slurry for 30min, to obtain Slurry;

[0046] (3) Leaching: pump the slurry described in step (2) to zinc oxide high-acid leaching tanks, and add 10m 3Slurry solution, then add zinc electrolysis waste liquid and sulfuric acid, wherein the acid content of the zinc electrolyte waste zinc electrolysis liquid is controlled at 165g / L, when the acid content of the zinc electrolysis waste liquid is 180g / L, no need to add sulfuric acid; Leach for 7.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com