Preparation method of high-strength high-conductivity copper-based composite material

A copper-based composite material, high conductivity technology, applied in the direction of polycrystalline material growth, chemical instruments and methods, crystal growth, etc., can solve the problems of poor compatibility, can not take into account the strength and conductivity of composite materials, etc., to achieve compatibility High, taking into account both strength and conductivity, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

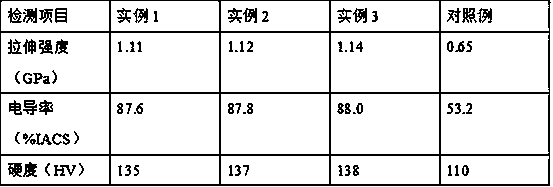

Examples

example 1

[0022] Mix rice husk and biogas slurry in a mass ratio of 1:5 and put it into a fermenter, seal the mouth of the tank and ferment for 3 days at a temperature of 35°C. Rinse 3 times and dry to obtain dry fermentation filter residue; mix the dry fermentation filter residue and iron powder according to the mass ratio of 50:1 and put it into a vacuum furnace, and feed argon into the vacuum furnace until all the air in the furnace is replaced. The temperature in the high-vacuum furnace is 1100°C, and the heat preservation reaction is carried out for 3 hours. After the reaction, the material is discharged, oxidized at 700°C for 3 hours and rinsed with 10% hydrofluoric acid for 3 times to obtain porous silicon carbide whiskers; Silicon carbide whiskers were soaked in a dopamine solution with a mass concentration of 2g / L for 1h, filtered to obtain a filter cake, and then the filter cake and a 30% copper chloride solution were mixed according to a mass ratio of 1:5, and then an ultrason...

example 2

[0024] Mix rice husk and biogas slurry at a mass ratio of 1:5 and put it into a fermenter, seal the mouth of the tank and ferment for 4 days at a temperature of 40°C. Rinse 4 times and dry to obtain dry fermentation filter residue; mix the dry fermentation filter residue and iron powder according to the mass ratio of 50:1 and put them into a vacuum furnace, and feed argon into the vacuum furnace until all the air in the furnace is replaced. The temperature in the high-vacuum furnace is 1300°C, and the heat preservation reaction is carried out for 4 hours. After the reaction, the material is discharged, and it is oxidized at 750°C for 4 hours and washed 4 times with 10% hydrofluoric acid to obtain porous silicon carbide whiskers; Silicon carbide whiskers were soaked in a dopamine solution with a mass concentration of 2g / L for 2h, filtered to obtain a filter cake, and then the filter cake and a cupric chloride solution with a mass fraction of 30% were mixed at a mass ratio of 1:5...

example 3

[0026]Mix rice husk and biogas slurry at a mass ratio of 1:5 and put it into a fermentation tank, seal the tank mouth and ferment for 5 days at a temperature of 45°C. Rinse 5 times and dry to obtain dry fermentation filter residue; mix the dry fermentation filter residue and iron powder according to the mass ratio of 50:1 and put them into a vacuum furnace, and feed argon into the vacuum furnace until all the air in the furnace is replaced. The temperature in the high-vacuum furnace is 1500°C, and the heat preservation reaction is carried out for 5 hours. After the reaction, the material is discharged, oxidized at 800°C for 5 hours, and washed 5 times with 10% hydrofluoric acid to obtain porous silicon carbide whiskers; Silicon carbide whiskers were soaked in a dopamine solution with a mass concentration of 2g / L for 2h, filtered to obtain a filter cake, and then the filter cake and a 30% copper chloride solution were mixed according to a mass ratio of 1:5, and an ultrasonic osc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com