A method of cellulose electrospinning

An electrospinning and cellulose technology, applied in the field of natural polymer material preparation, can solve the problems of small free volume, low cellulose concentration and high viscosity, and achieves the promotion of stretching and fiber formation, inhibition of hydrogen bonding, and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] S1, immersing cellulose in methanol with a mass fraction of 95%, so that the cellulose is partially swollen to obtain swollen cellulose, wherein the mass fraction of methanol in the swollen cellulose is 10%;

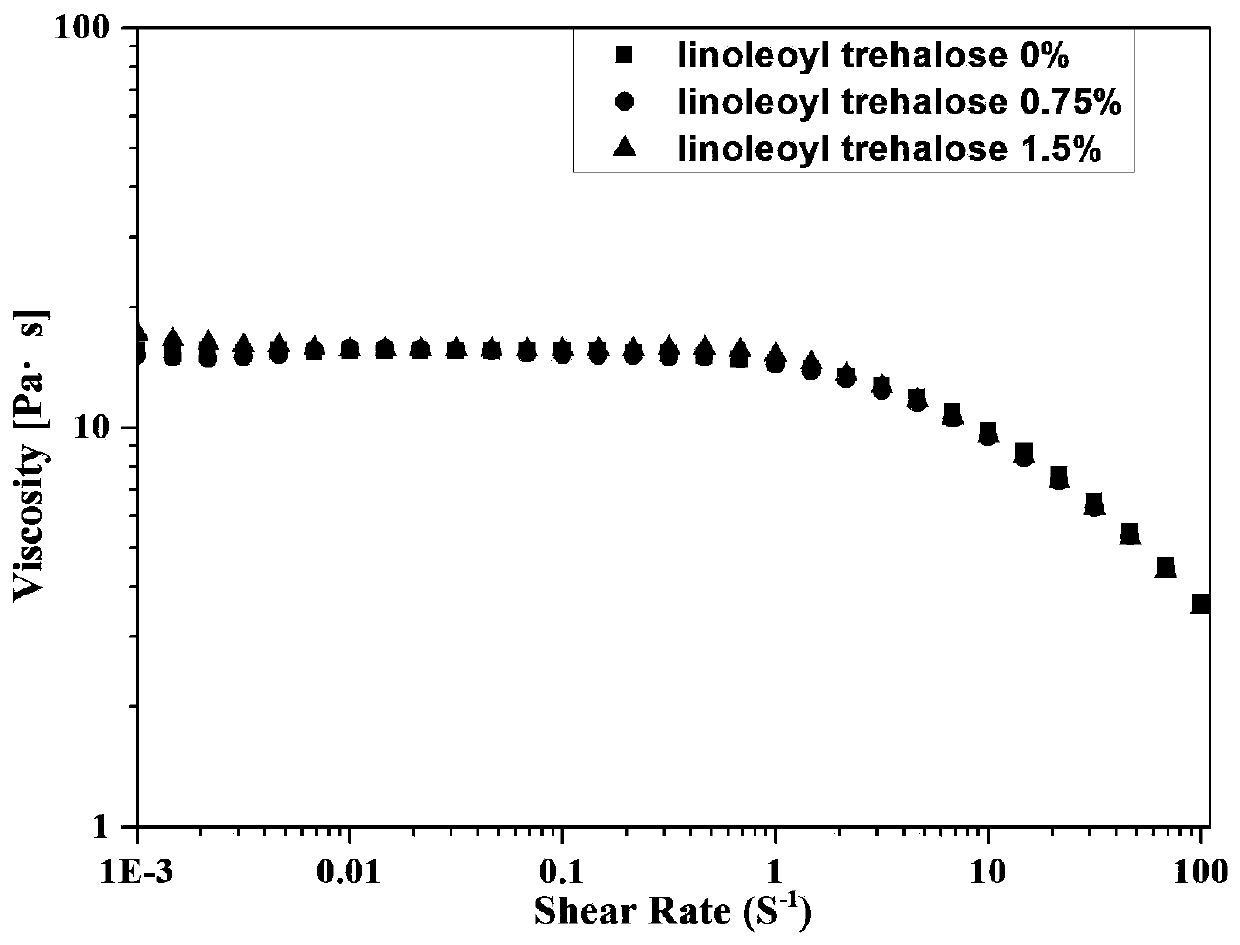

[0037] S2, dissolving lithium chloride in dimethylacetamide, then adding linoleic acid trehalose monoester to obtain a mixture, wherein the mass fraction of lithium chloride in the mixture is 7%, the mass of linoleic acid trehalose monoester A fraction of 0.5%;

[0038] S3, adding the swollen cellulose obtained in step S1 to the mixture obtained in step S2 to obtain a cellulose solution, wherein the mass fraction of cellulose in the cellulose solution is 1.5%; and

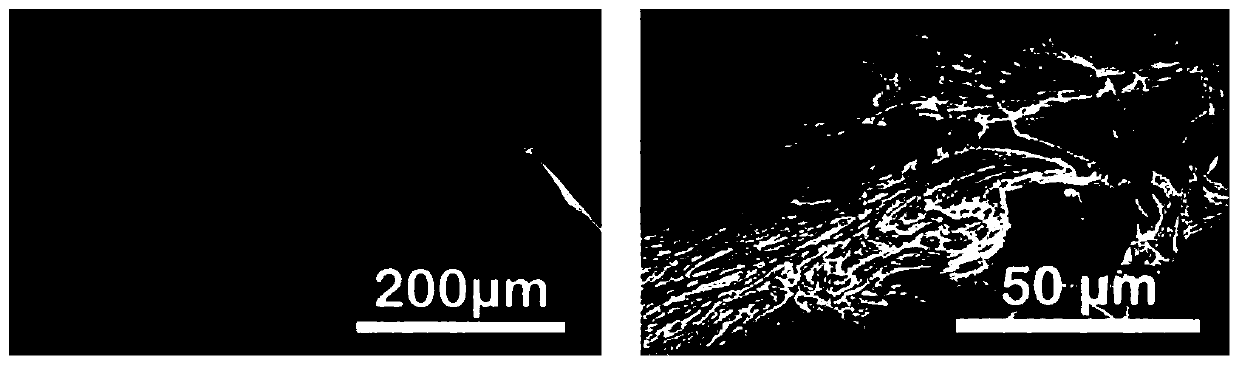

[0039]S4, filter and remove impurities from the cellulose solution obtained in S3, put it into an injection syringe, connect it with a stainless steel needle with an inner diameter, cut the needle into a flat mouth and polish it smoothly, and then install the syringe on the pusher at a speed of 0.3mL / ...

Embodiment 2

[0041] S1, immersing the cellulose in ethanol with a mass fraction of 95%, so that the cellulose is partially swollen to obtain swollen cellulose, wherein the mass fraction of methanol in the swollen cellulose is 80%;

[0042] S2, dissolve lithium chloride in dimethylacetamide, then add linoleic acid trehalose monoester to obtain a mixture, wherein the mass fraction of lithium chloride in the mixture is 9%, and the mass of linoleic acid trehalose monoester A score of 2%;

[0043] S3, adding the swollen cellulose obtained in step S1 to the mixture obtained in step S2 to obtain a cellulose solution, wherein the mass fraction of cellulose in the cellulose solution is 3%; and

[0044] S4, filter and remove impurities from the cellulose solution obtained in S3, put it into the injection syringe, connect it with a stainless steel needle with an inner diameter, cut the needle into a flat mouth and polish it smoothly, then install the syringe on the pusher, and the advancing speed is ...

Embodiment 3

[0046] S1, immersing cellulose in methanol with a mass fraction of 96%, so that the cellulose is partially swollen to obtain swollen cellulose, wherein the mass fraction of methanol in the swollen cellulose is 20%;

[0047] S2, dissolving lithium chloride in dimethylacetamide, then adding linoleic acid trehalose monoester to obtain a mixture, wherein the mass fraction of lithium chloride in the mixture is 8%, the mass of linoleic acid trehalose monoester The score is 10%;

[0048] S3, adding the swollen cellulose obtained in step S1 to the mixture obtained in step S2 to obtain a cellulose solution, wherein the mass fraction of cellulose in the cellulose solution is 2%; and

[0049] S4, filter the cellulose solution obtained in S3 to remove impurities and put it into an injection syringe, externally connect a stainless steel needle with an inner diameter, cut the needle into a flat mouth and polish it smoothly, then install the syringe on the pusher at a speed of 0.5mL / h Sque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com