Polyether type polyurethane solar heat-absorbing coating and preparation method thereof

A technology of polyether polyurethane and solar heat absorption, which is applied in the field of solar heat absorption, can solve the problems of low thermal efficiency of solar collectors, complicated process flow, and poor weather resistance of coatings, and achieves easy industrial production, simple preparation process, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

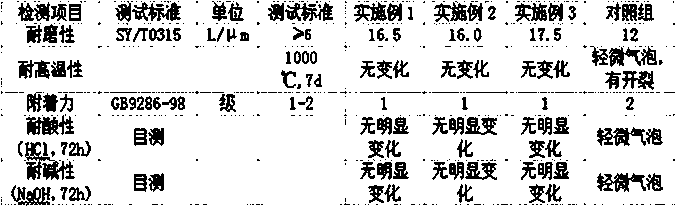

Examples

Embodiment 1

[0024] A polyether polyurethane solar heat absorbing coating and a preparation method thereof, wherein the coating is made of the following raw materials in parts by weight:

[0025] 75 parts of castor oil modified polyether polyurethane, 20 parts of polyethylene glycol, 45 parts of light absorbing agent, 15 parts of light absorption accelerator, 4 parts of dibutyl phthalate, 7 parts of titanate coupling agent, EFKA- 7 parts of 3580, 7 parts of polysiloxane, 3 parts of polyoxyethylene polyoxypropylene glyceryl ether.

[0026] The light absorbing agent is made black by using cobalt blue powder, cobalt manganese copper oxide and enamel black.

[0027] The light absorption accelerator uses 2-chloro-2-(2-fluorophenyl)-1-cyclobutylethanone and 2-(2-nitroanilino)-3-cyano-5-propylthio It is obtained by mixing in a ratio of 1:1.

[0028] The castor oil modified polyether polyurethane is prepared from the following raw materials in parts by weight: 26 parts of castor oil, 65 parts of...

Embodiment 2

[0034] A polyether polyurethane solar heat absorbing coating and a preparation method thereof, wherein the coating is made of the following raw materials in parts by weight:

[0035] 50 parts of castor oil modified polyether polyurethane, 10 parts of polyethylene glycol, 35 parts of light absorbing agent, 10 parts of light absorption accelerator, 3 parts of dibutyl phthalate, 5 parts of titanate coupling agent, EFKA- 5 parts of 3580, 4 parts of polysiloxane, 2 parts of polyoxyethylene polyoxypropylene glyceryl ether.

[0036] The light absorbing agent is made red by using chromium oxide green powder, selenium cadmium sulfide powder and iron oxide red powder.

[0037] The light absorption accelerator uses 2-chloro-2-(2-fluorophenyl)-1-cyclobutylethanone and 2-(2-nitroanilino)-3-cyano-5-propylthio It is obtained by mixing in a ratio of 1:1.

[0038] The castor oil modified polyether polyurethane is prepared from the following raw materials in parts by weight: 25 parts of casto...

Embodiment 3

[0044] A polyether polyurethane solar heat absorbing coating and a preparation method thereof, wherein the coating is made of the following raw materials in parts by weight:

[0045] 100 parts of castor oil modified polyether polyurethane, 30 parts of polyethylene glycol, 55 parts of light absorbing agent, 20 parts of light absorption accelerator, 5 parts of dibutyl phthalate, 10 parts of titanate coupling agent, EFKA- 10 parts of 3580, 10 parts of polysiloxane, 5 parts of polyoxyethylene polyoxypropylene glyceryl ether.

[0046] The light absorbing agent is dark green made of enamel black, chromium oxide green, iron oxide red, cadmium sulfide, and cobalt blue.

[0047] The light absorption accelerator uses 2-chloro-2-(2-fluorophenyl)-1-cyclobutylethanone and 2-(2-nitroanilino)-3-cyano-5-propylthio It is obtained by mixing in a ratio of 1:1.

[0048] The castor oil modified polyether polyurethane is prepared from the following raw materials in parts by weight: 27 parts of ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com