Macroporous adsorption resin regenerated waste liquid alkali recovery process device and method

A technology for resin regeneration and regeneration of waste liquid, which is applied in the field of water treatment and can solve the problems of high cost of treatment process and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

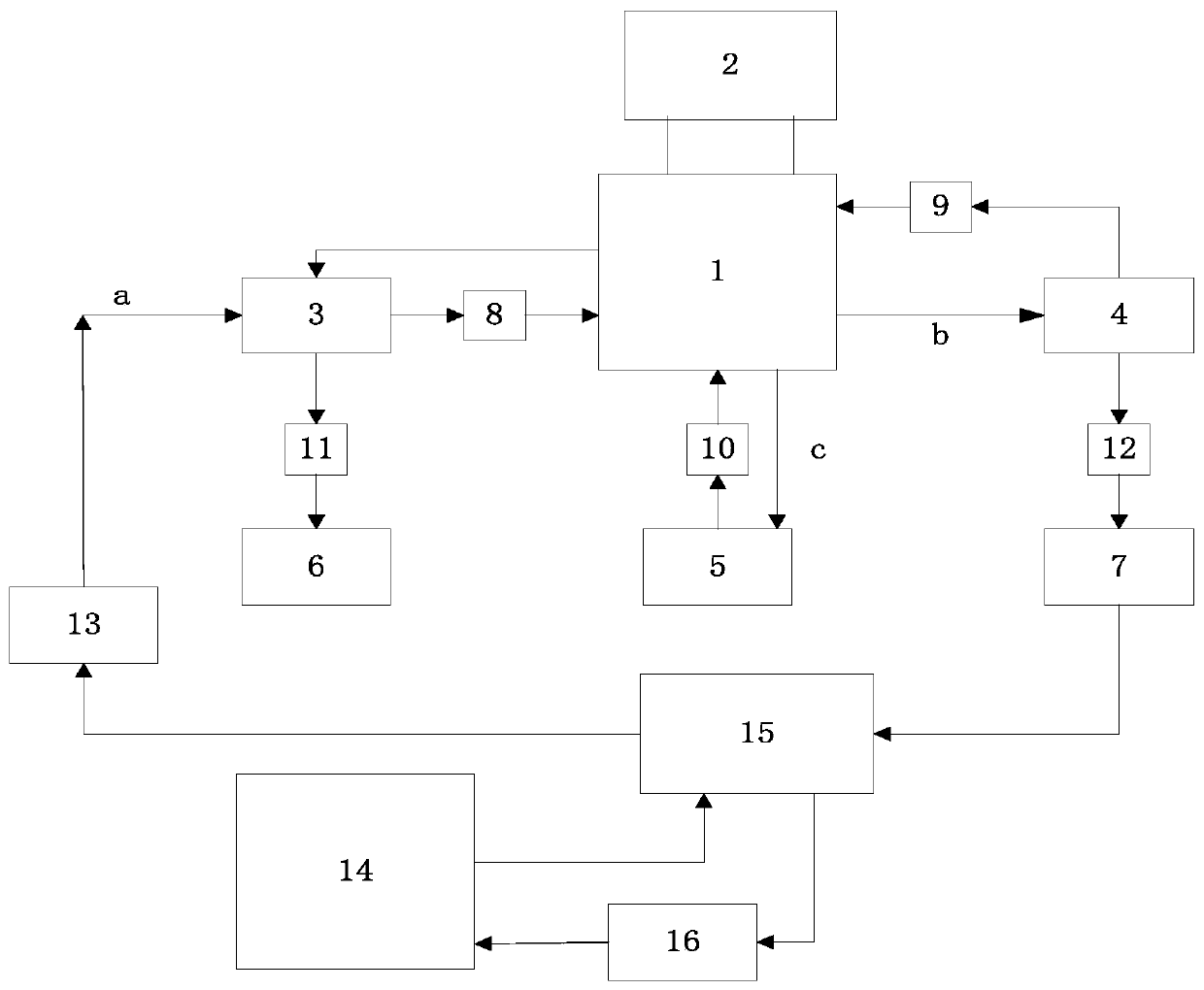

[0057] A macroporous adsorption resin regenerated waste liquid alkali recovery process device, its structure schematic diagram is shown in figure 1 . The device is a recovery process device for bypass regeneration waste liquid alkali on the macroporous adsorption resin-lye regeneration system, and separates alkali and organic matter from the regeneration waste liquid alkali, and the separated alkali liquor is reused for macroporous adsorption resin to regenerate alkali Liquid preparation, the regenerated waste liquid alkali recovery process device described in it includes a homogeneous ion exchange membrane electrodialysis device, a raw water circulation pool 3, an extreme water circulation pool 5, a recycled lye circulation pool 4, a raw water circulation pump 8, and an extreme water circulation pump 10. Recover the lye circulation pump 9.

[0058] The homogeneous ion exchange membrane electrodialysis device includes a DC power supply 2 and a homogeneous ion exchange membran...

Embodiment 2

[0091] A macroporous adsorption resin regenerated waste liquid alkali recovery process device, the same as that described in Example 1.

[0092] The process of realizing recycling of the regenerated waste liquid alkali recovery process device includes:

[0093] The macroporous adsorption resin regenerated waste liquid alkali a enters the raw water circulation pool 3, is lifted by the raw water circulation pump 8 and processed by the homogeneous ion exchange membrane stack 1, and the generated raw water from which the lye is removed returns to the raw water circulation pool 3 to form Separate closed loop.

[0094] The low-concentration lye with a mass concentration of 0.05% is pre-prepared in the reclaimed lye circulation pool 4 as the initial reclaimed lye, which is lifted to the homogeneous ion-exchange membrane stack 1 by the reclaimed liquid circulation pump 9 for processing, and the recovered lye produced is The b outlet water returns to recovery lye circulation pool 4 ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com