Electrolyte/electrode interface integrated construction technology of all-solid-state lithium battery

An electrode interface and electrolyte technology, applied in battery electrodes, electrode carriers/current collectors, secondary batteries, etc., can solve the problems of insufficient contact, affecting battery performance, large gaps, etc., to reduce interface impedance, optimize interface contact, The effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

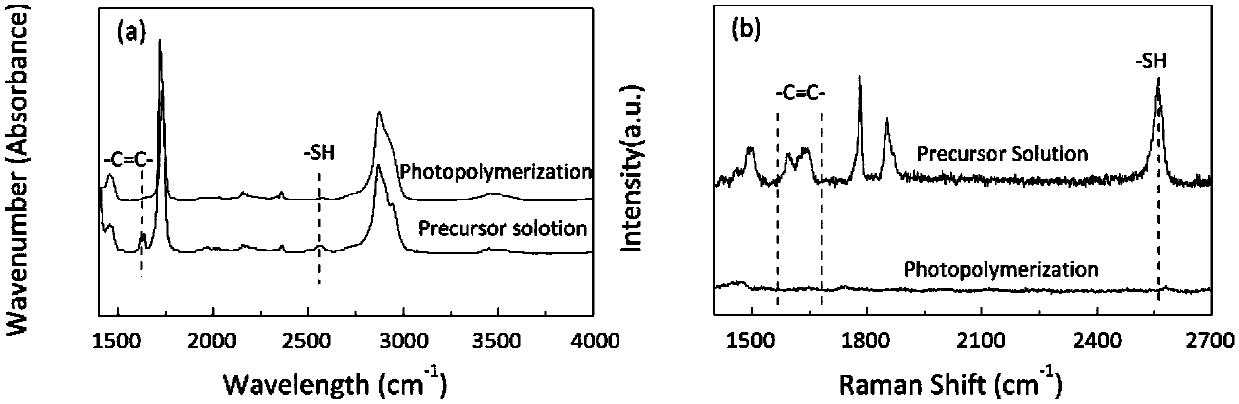

[0070] Under the protection of an inert atmosphere, A) The cathode material LiFePO 4 , Carbon black, polyethylene glycol diacrylate (weight average molecular weight 1000), pentaerythritol tetrakis (3-mercaptopropionic acid) ester according to a certain mass ratio 7:1:1:1 weighed into acetonitrile, and then added oxygen lithium ratio EO / Li=18:1 LiClO 4 , Stir uniformly at 50°C to obtain a precursor solution; B) After weighing pentaerythritol tetrakis (3-mercaptopropionic acid) ester and polyethylene glycol diacrylate (weight average molecular weight 1000) at a molar ratio of 1:1, Mix and stir in the dark, add LiTFSI according to the EO / Li molar ratio of 18:1, continue to stir in acetonitrile to obtain a slurry; evenly scrape the precursor solution on the current collector, and dry the slurry evenly Coated on the surface of the current collector coated with the precursor solution. After being fully infiltrated, irradiate it with ultraviolet light with a wavelength of 200-500nm for...

Embodiment 2

[0076] Under the protection of an inert atmosphere, A) Cathode material LiFePO 4 , Carbon black, pentaerythritol tetrakis (3-mercaptopropionic acid) ester and polyethylene glycol diacrylate (weight average molecular weight 2000) according to a certain mass ratio 7:1:1:1 weighed into tetrahydrofuran, and then added oxygen to lithium ratio EO / Li=18:1 LiClO 4 , Stir uniformly at 50°C to obtain a precursor solution; B) After weighing pentaerythritol tetrakis (3-mercaptopropionic acid) ester and polyethylene glycol diacrylate (weight average molecular weight 2000) at a molar ratio of 1:1, Avoid light, mix and stir, add LiClO according to the EO / Li molar ratio of 18:1 4 , Continue to stir uniformly in acetonitrile to obtain a slurry; evenly scrape the precursor solution on the current collector, after drying, coat the slurry evenly on the surface of the current collector coated with the precursor solution, and then use The ultraviolet light with a wavelength of 200-500nm is irradiated...

Embodiment 3

[0082] Under the protection of an inert atmosphere, A) Cathode material LiFePO 4 , Carbon black, pentaerythritol tetrakis (3-mercaptopropionic acid) ester and polyethylene glycol diacrylate (weight average molecular weight are respectively 200, 400, 600, 1000) according to a certain mass ratio 7:1:1:1 weighed and added In acetonitrile, add LiBOB with oxygen-lithium ratio EO / Li=14:1,16:1,18:1,20:1,22:1, and stir evenly at 50℃ to obtain a precursor solution; B) The pentaerythritol tetrakis (3-mercaptopropionic acid) ester and polyethylene glycol diacrylate (weight-average molecular weight are respectively 200, 400, 600, 1000) are respectively weighed at a molar ratio of 1:1, then mixed and stirred in the dark. Add LiBOB with different EO / Li molar ratios (14:1, 16:1, 18:1, 20:1, 22:1), continue to stir in acetonitrile to obtain slurry; evenly scrape the precursor solution on the set On the fluid, after drying, the slurry is evenly coated on the surface of the current collector coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com