A preparing method of a sodium bismuthate based visible light catalysis paper material

A technology of sodium bismuth and catalytic paper is applied in the field of preparation of sodium bismuth-based visible light catalytic paper materials, which can solve the problems such as the photocatalytic efficiency, activity and chemical stability have not been greatly improved and breakthroughs, and ensure the adsorption And the effect of catalytic activity, simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

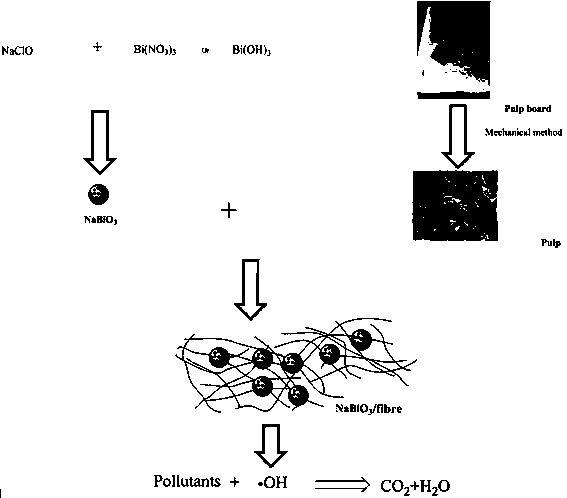

[0027] Preparation of sodium bismuthate photocatalytic paper composites using bismuth nitrate as bismuth source

[0028] 1. Preparation of sodium bismuthate

[0029] First prepare sodium hypochlorite, weigh 10-20 g of sodium hydroxide and dissolve it in water, cool it to below 10°C with ice water, feed chlorine gas under stirring to reach saturation, and then add 10-15 g of sodium hydroxide to control The temperature is between 10°C and 20°C, and the precipitated crystals are separated and filtered to obtain sodium hypochlorite. Using bismuth nitrate as the source of bismuth, add a small amount of it to the sodium hypochlorite test solution several times under strong stirring, and control the temperature at 20-30°C. After 60-80 minutes, a yellow sodium bismuthate precipitate was obtained, which was left to stand for stratification, rinsed with 1% sodium hydroxide, filtered, and then dried in a vacuum oven for 24-30 hours to obtain a sodium bismuthate sample.

[0030] 2. Prepa...

Embodiment 2

[0039] Preparation of sodium bismuthate-based visible light photocatalytic paper materials using bismuth hydroxide as bismuth source

[0040] 1. Preparation of sodium bismuthate

[0041] First prepare sodium hypochlorite, weigh 10-20 g of sodium hydroxide and dissolve it in water, cool it to below 10°C with ice water, feed chlorine gas under stirring to reach saturation, and then add 10-15 g of sodium hydroxide to control The temperature is 10°C-20°C, and the precipitated crystals are separated and suction-filtered to obtain sodium hypochlorite. Using bismuth hydroxide as the source of bismuth, add a small amount of it to the sodium hypochlorite test solution several times under strong stirring, and control the temperature at 20-30°C. After reacting for 60-80 minutes, a yellow sodium bismuthate precipitate was obtained, which was left to stand for stratification, rinsed with 1% sodium hydroxide, filtered, and then dried in a vacuum oven for 24-30 hours to obtain a sodium bismu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com