Preparation method of pattered metallic textile on the basis of pretreatment with dopamine

A patterned metal and dopamine technology, applied in textiles and papermaking, fiber treatment, metal material coating technology, etc., can solve the problems of unfriendly environment, complex process, lower sintering temperature, etc., and achieve good conductivity and electromagnetic shielding performance , uniform coating and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

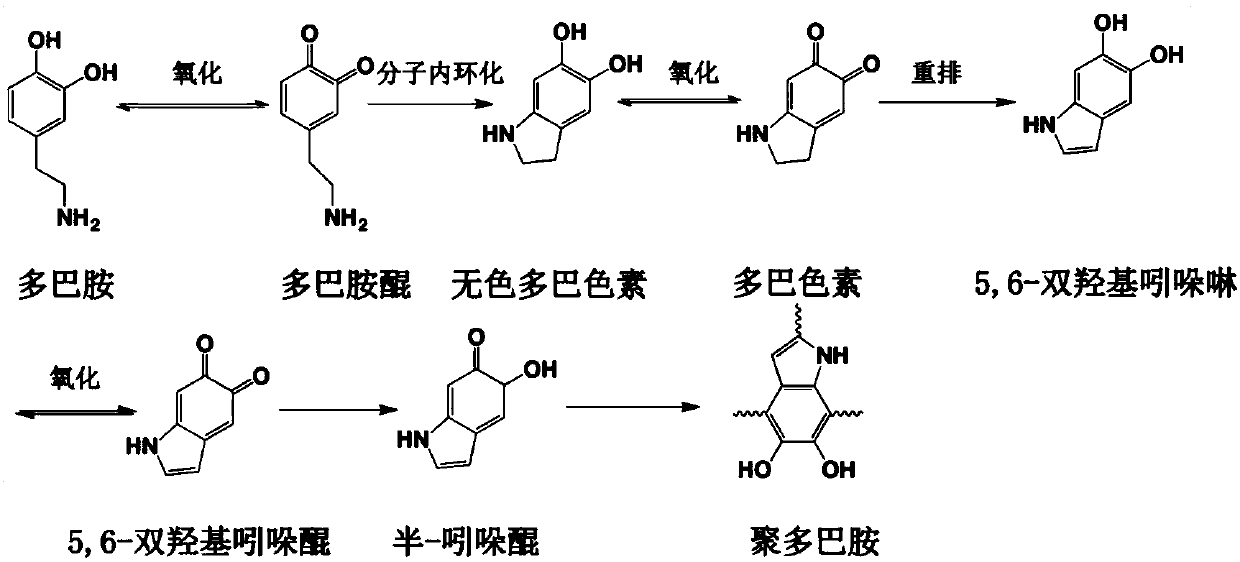

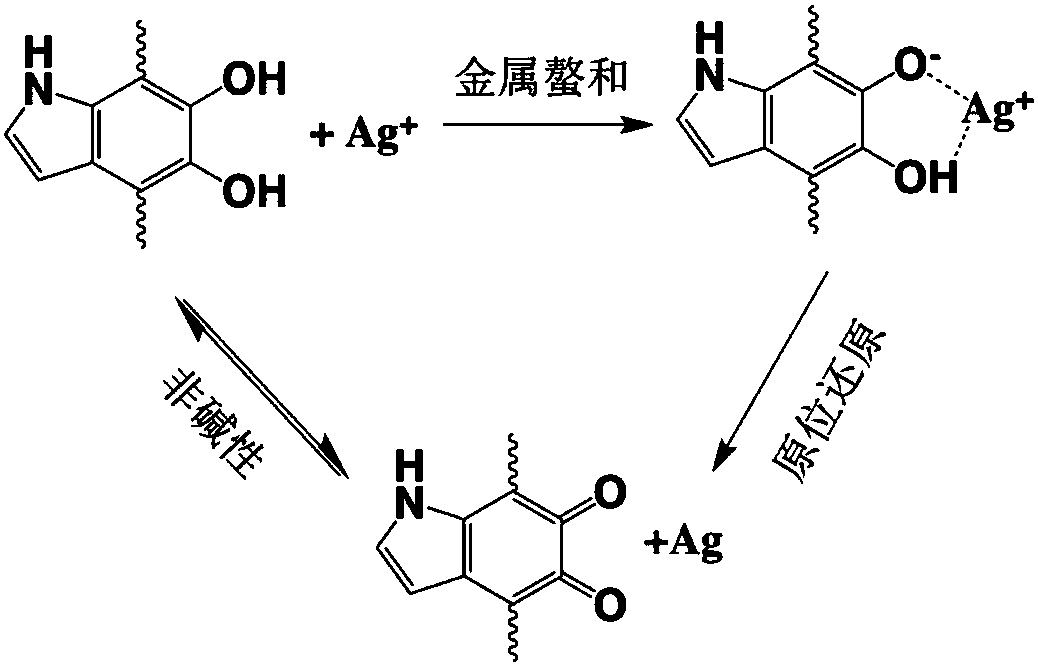

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Adjust the pH value of the dopamine solution with a concentration of 2 mg / mL to 8.5 with tris-hydrochloric acid buffer solution, then gently stir at 25°C for 24 hours to oxidize and self-polymerize to form polydopamine, and add alginic acid Sodium adjusts the viscosity to 5000-10000cP to form a dopamine-modified slurry.

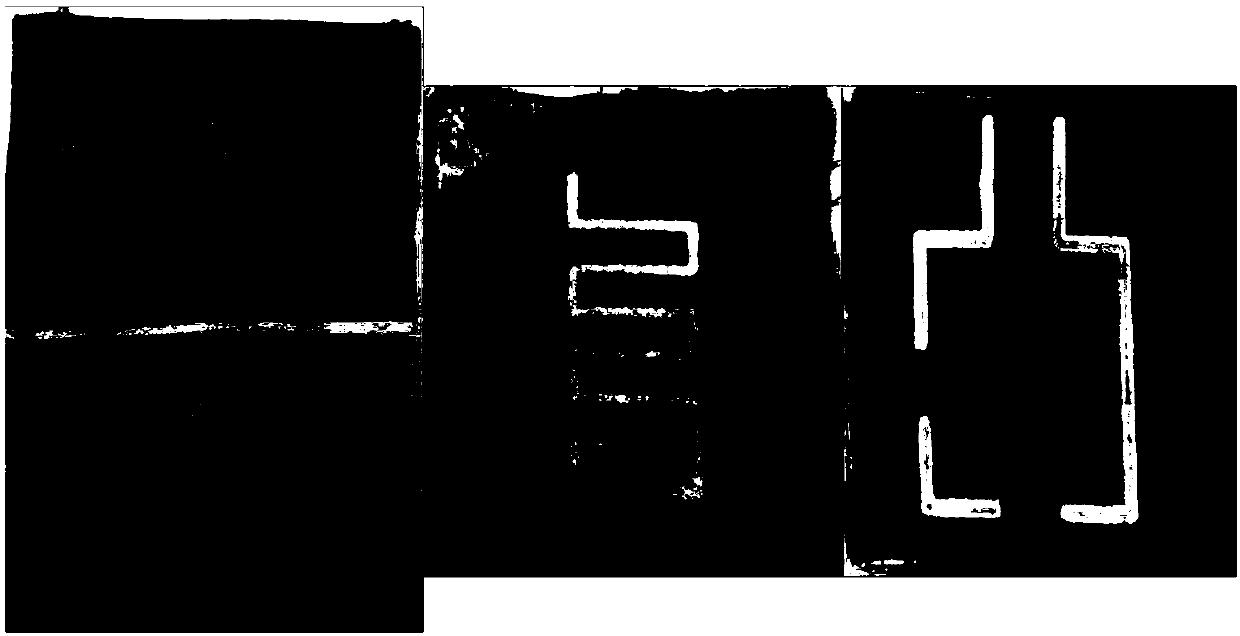

[0042] (2) Print the dopamine-modified slurry obtained in step (1) on the surface of the polyester fabric to form a pattern by screen printing technology, dry at 60°C for 20 minutes, and then repeat printing and drying to obtain a dopamine-modified pattern Polyester base.

[0043] (3) Immerse the dopamine-modified patterned polyester substrate obtained in step (2) in 1% AgNO 3 After 24 hours in the solution, it was taken out, washed with distilled water, and dried at 60° C. for 20 minutes to obtain an activated patterned polyester substrate.

[0044] (4) To 40g / L AgNO 3Add ammonia water dropwise to the solution from cloudy to clear, then add 120...

Embodiment 2

[0047] (1) Adjust the pH value of the dopamine solution with a concentration of 2 mg / mL to 8.5 with tris-hydrochloric acid buffer solution, then gently stir at 25°C for 24 hours to oxidize and self-polymerize to form polydopamine, and add alginic acid Sodium adjusts the viscosity to 5000-10000cP to form a dopamine-modified slurry.

[0048] (2) Print the dopamine-modified slurry obtained in step (1) on the surface of the polyester fabric to form different patterns by screen printing technology, dry at 60°C for 20 minutes, and then repeat printing and drying to obtain dopamine-modified Patterned polyester base.

[0049] (3) Immerse the dopamine-modified patterned polyester substrate obtained in step (2) in 1% AgNO 3 and polyvinylpyrrolidone in a mixed solution for 24 hours, then taken out, washed with distilled water, and dried at 60°C for 20 minutes to obtain an activated patterned polyester substrate.

[0050] (4) To 40g / L AgNO 3 Add ammonia water dropwise to the solution f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com