Recycling method for sodium-alkali-process desulphurization liquid

A treatment method and desulfurization liquid technology, applied in chemical instruments and methods, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of high energy consumption and high suspended solids content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

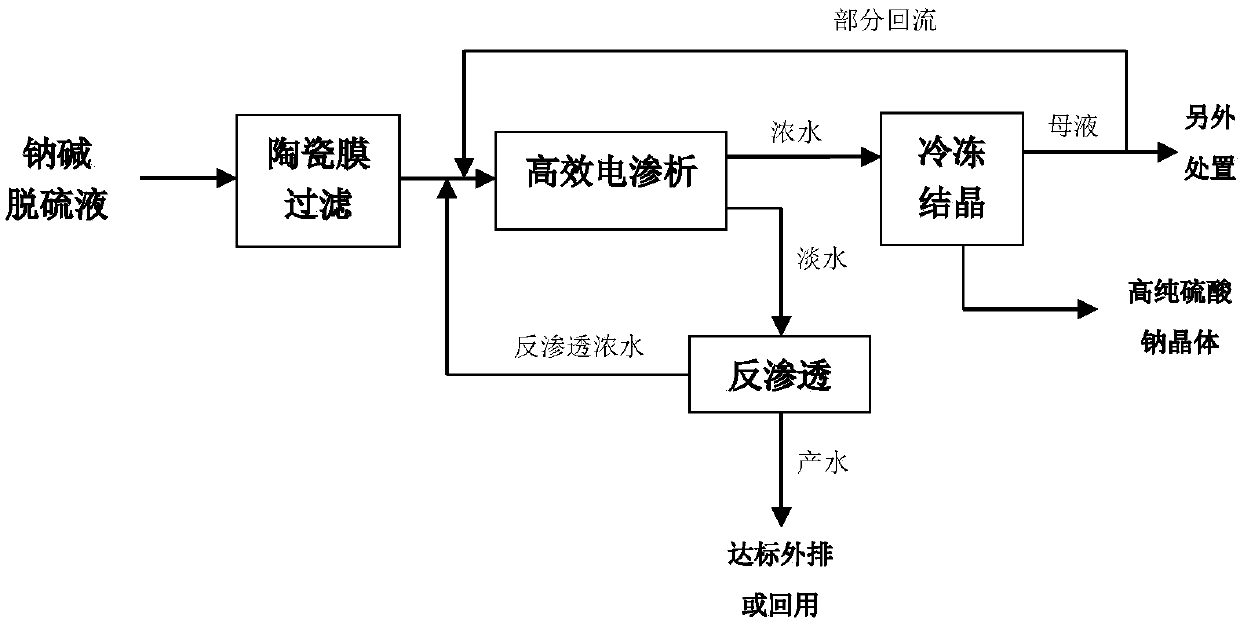

Image

Examples

Embodiment 1

[0076] The main water quality characteristics of sodium-alkali desulfurization liquid are: total dissolved solids 60000mg / L, suspended solids 1000mg / L, oil content 0mg / L, Na + 18000mg / L, Cl - 100mg / L, SO 4 2- 42000mg / L, COD 0mg / L, Mg 2+ 15mg / L, Ca 2+ 100mg / L, soluble silicon 2mg / L.

[0077] The processing steps are as follows:

[0078] The first step is to use ceramic membrane filtration to remove the suspended solids in the sodium-alkali desulfurization solution. The ceramic membrane filter selects a ceramic membrane filter element with a pore size of 50nm, and the filtration pressure is set to 0.08MPa. The content of suspended solids in the water filtered by the ceramic membrane is 1.0mg / L; The suspended solids separated by ceramic membrane filtration are collected and solidified, and then transported outside for treatment;

[0079] In the second step, the water filtered by the ceramic membrane enters the high-efficiency electrodialysis unit for concentration. The high...

Embodiment 2

[0084] The main water quality characteristics of sodium-alkali desulfurization liquid are: total dissolved solids 65000mg / L, suspended solids 1500mg / L, oil content 0.3mg / L, Na + 20000mg / L, Cl - 120mg / L, SO 4 2- 45000mg / L, COD 10mg / L, Mg 2+ 17mg / L, Ca 2+ 110mg / L, soluble silicon 4mg / L.

[0085] The processing steps are as follows:

[0086] The first step is to use ceramic membrane filtration to remove suspended solids in the sodium-alkali desulfurization solution. For ceramic membrane filtration, a ceramic membrane filter element with a pore size of 100nm is selected, and the filtration pressure is set to 0.10MPa. The content of suspended solids in the water filtered by the ceramic membrane is 0.7mg / L; the suspended solids separated by ceramic membrane filtration are collected and solidified, and then transported outside for treatment;

[0087] In the second step, the water filtered by the ceramic membrane enters the high-efficiency electrodialysis unit for concentration....

Embodiment 3

[0092] The main water quality characteristics of sodium-alkali desulfurization liquid are: total dissolved solids 75000mg / L, suspended solids 2500mg / L, oil content 0.8mg / L, Na + 23000mg / L, Cl - 140mg / L, SO 4 2- 52000mg / L, COD 20mg / L, Mg 2+ 23mg / L, Ca 2+ 135mg / L, dissolved silicon 5mg / L.

[0093] The processing steps are as follows:

[0094] The first step is to use ceramic membrane filtration to remove suspended solids in the sodium-alkali desulfurization solution. For ceramic membrane filtration, a ceramic membrane filter element with a pore size of 100nm is selected, and the filtration pressure is set to 0.12MPa. The content of suspended solids in the water filtered by the ceramic membrane is 0.8mg / L; The suspended solids separated by ceramic membrane filtration are collected and solidified and then transported out for treatment;

[0095] In the second step, the water filtered by the ceramic membrane enters the high-efficiency electrodialysis unit for concentration. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com